3-1

3. Operation

3-1 Inspection and Preparation Before Operation

Check the following before starting operation.

(1) Check if connection is correct.

Especially check if the power cables are connected to

inverter output terminals U, V and W and that the

grounding cable is grounded without fail.

(2) Check for short circuits between terminals and exposed

live parts and ground faults.

(3) Check for loose terminals, connectors and screws.

(4) Check if the motor is separated from mechanical equipment.

(5) Turn the switches off so that the inverter does not start or operate erroneously at power-on.

(6) After the power is turned on, check the following.

a. Check if the keypad panel shows an alarm.

b. Check if the fan built in the inverter rotates. (1.5 kW or above)

!

!!

!

WARNING

• Be sure to install the terminal cover before turning the power on.

Do not remove the cover during power application.

• Do not operate switches with wet hands.

Otherwise electric shock could occur.

3-2 Operation Method

There are various operation methods. Refer to chapter 4 "Keypad Panel" and chapter 5 "Selecting

Functions" to select the method most suitable for the purpose and operation specification. Table

3-2-1 shows general operation methods.

3-3 Test Operation

After checking for errors in section 3-1, perform a

test operation.

In the factory shipment state, the inverter is in the

keypad panel operation mode.

(1) Turn the power on and check that the LED

blinks while indicating the 0.00 Hz frequency.

(2) Using the key, set the frequency to a

low frequency such as 5 Hz.

(3) To turn forward: F02 = 2

To reverse: F02 = 3

After setting the above, press the

RUN

key to

start operation. To stop, press the

STOP

key.

(4) Check the following points.

a. Check if the direction of rotation is correct.

b. Check for smooth rotation without motor humming or excessive vibration.

c. Check for smooth acceleration and deceleration.

(5) Referring to function code P04 Motor 1 (auto tuning), tune the motor constant.

When no abnormality is found, raise the operation frequency to check.

After checking for correct operation during the above test operation, start normal operation.

Caution 1: If any abnormality is found to the inverter or motor, immediately stop operation and

determine the cause referring to chapter 7 Troubleshooting.

Caution 2: If voltage is applied to the L1/R, L2/S and L3/T or L1/L and L2/N main circuit power

supply terminals even after the inverter stops, the inverter output terminals U, V and W

are live and you will be hit by electric shock when touching the terminals. As well, the

smoothing capacity is not discharged immediately after the power is turned off and it

takes time for the capacitor to be discharged.

To touch the electric circuit after turning the power off, check that the charge lamp is unlit

and check for safe voltage using a multimeter.

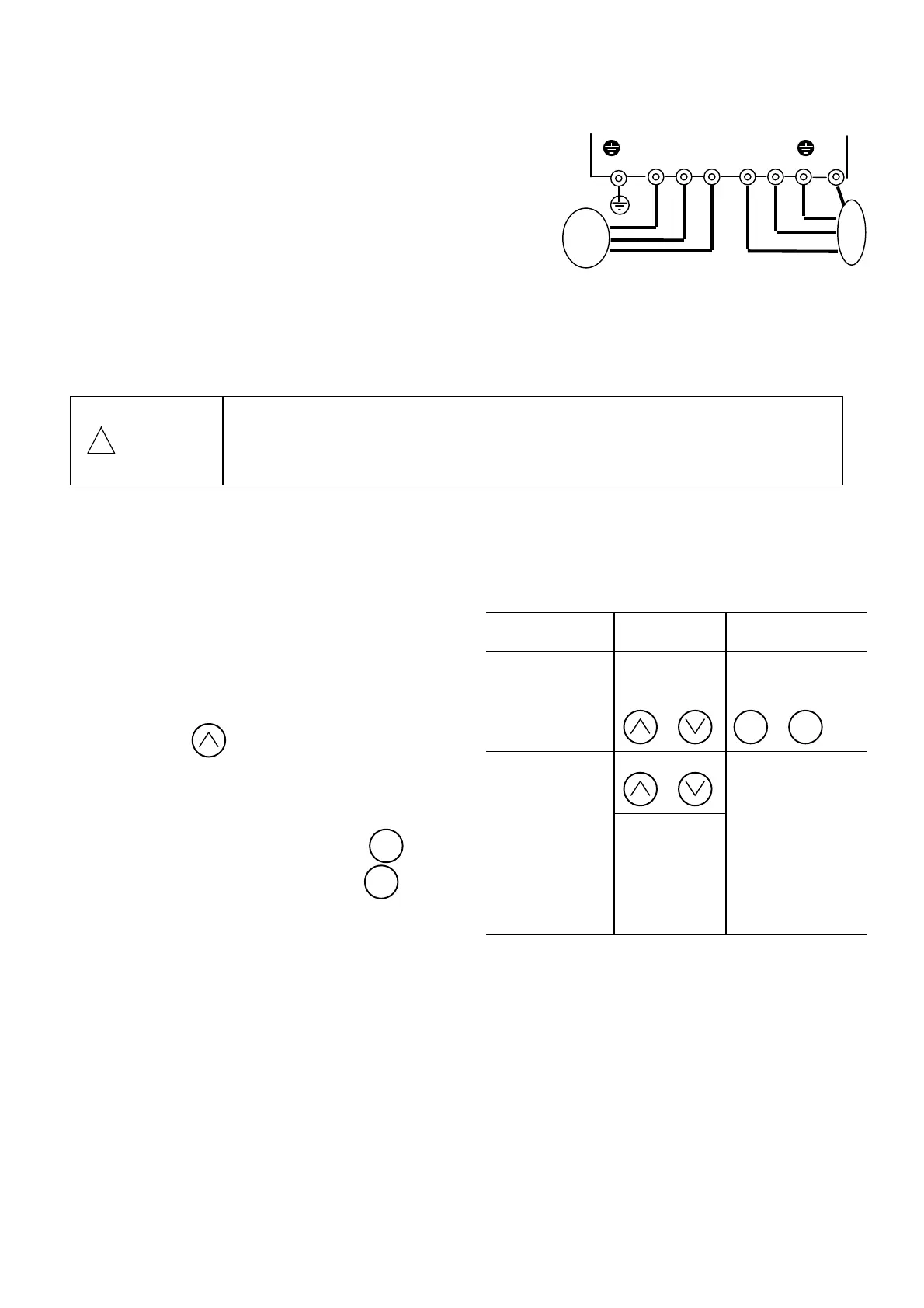

Operation

method

Frequency

setting

Operation

command

Operation

using keypad

panel

Keypad

panel keys

,

Keypad panel

keys

RUN

,

STOP

,

Operation

using external

signal terminal

Potentiometer

or analog

voltage,

current or

multistep

speed

operation

Contact input

(switch),

terminals

FWD-P24,

terminals

REV-P24

Table 3-2-1 General operation methods

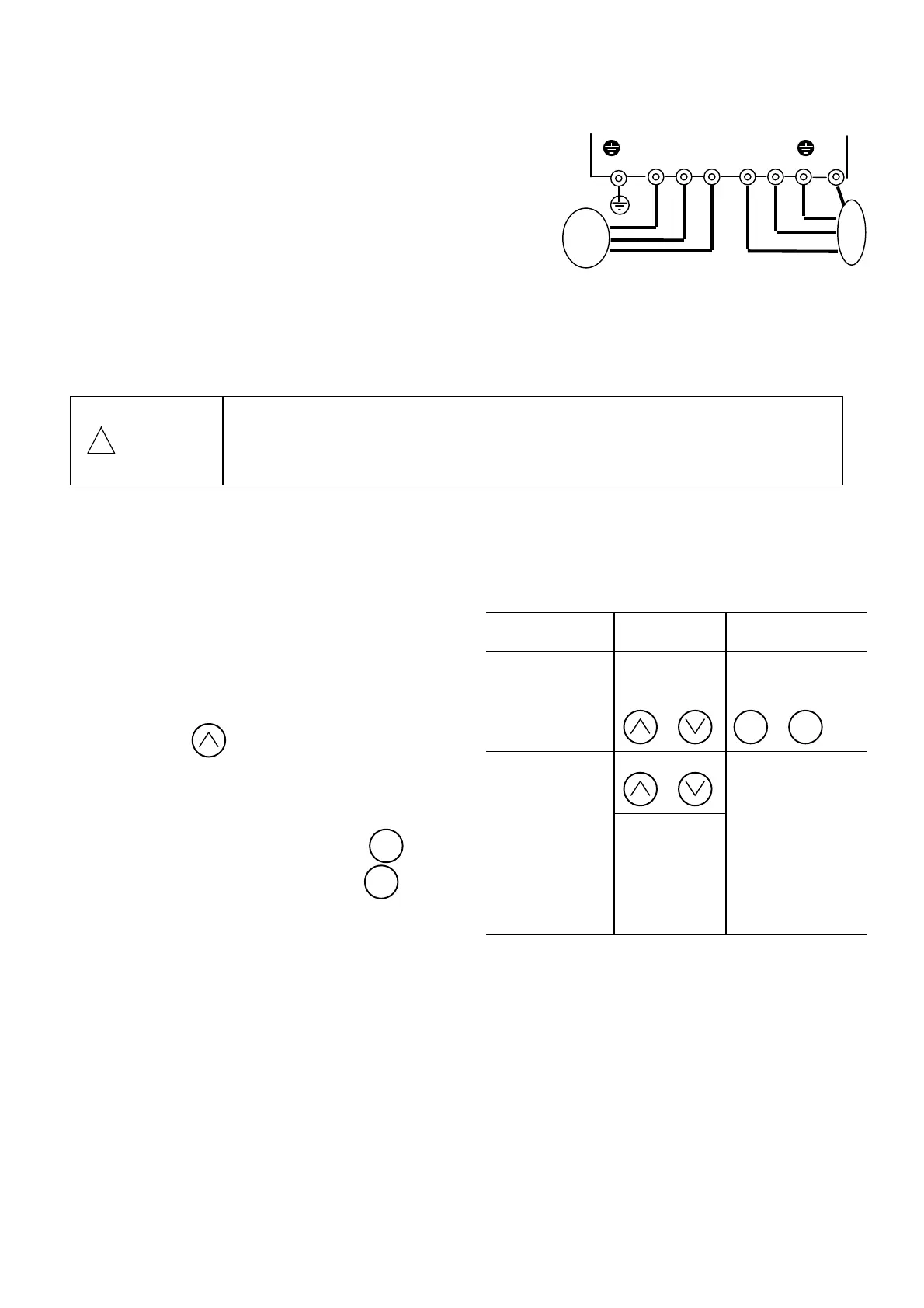

Fig. 3-1-1

Inverter connection diagram

Motor

Power

supply

Inverter

G L1/R L2/S L3/T U V W G

(L1/L) (L2/N)

Loading...

Loading...