5-14

F09

Torque boost 1

This function is for motor 1. The following

options can be selected.

- Selection of load characteristics such as

automatic torque boost, square reduction

torque load, proportional torque load and

constant torque load.

- Correction of magnetic flux shortage of motor

in accordance with the voltage drop in low

frequency zone, and torque boost during low

speed operation (boosting of V/f

characteristics).

Setting range

Description of selection

0 Automatic torque boost characteristics

where the torque boost value of the

constant torque load is automatically

adjusted (refer to function code P04

"Motor 1 (“(Tuning)").

1 Square reduction torque characteristics

for fan and pump loads

2 Proportional torque characteristics for

intermediate load between the square

reduction torque and torque

characteristics.

3 to 31 Constant torque characteristics

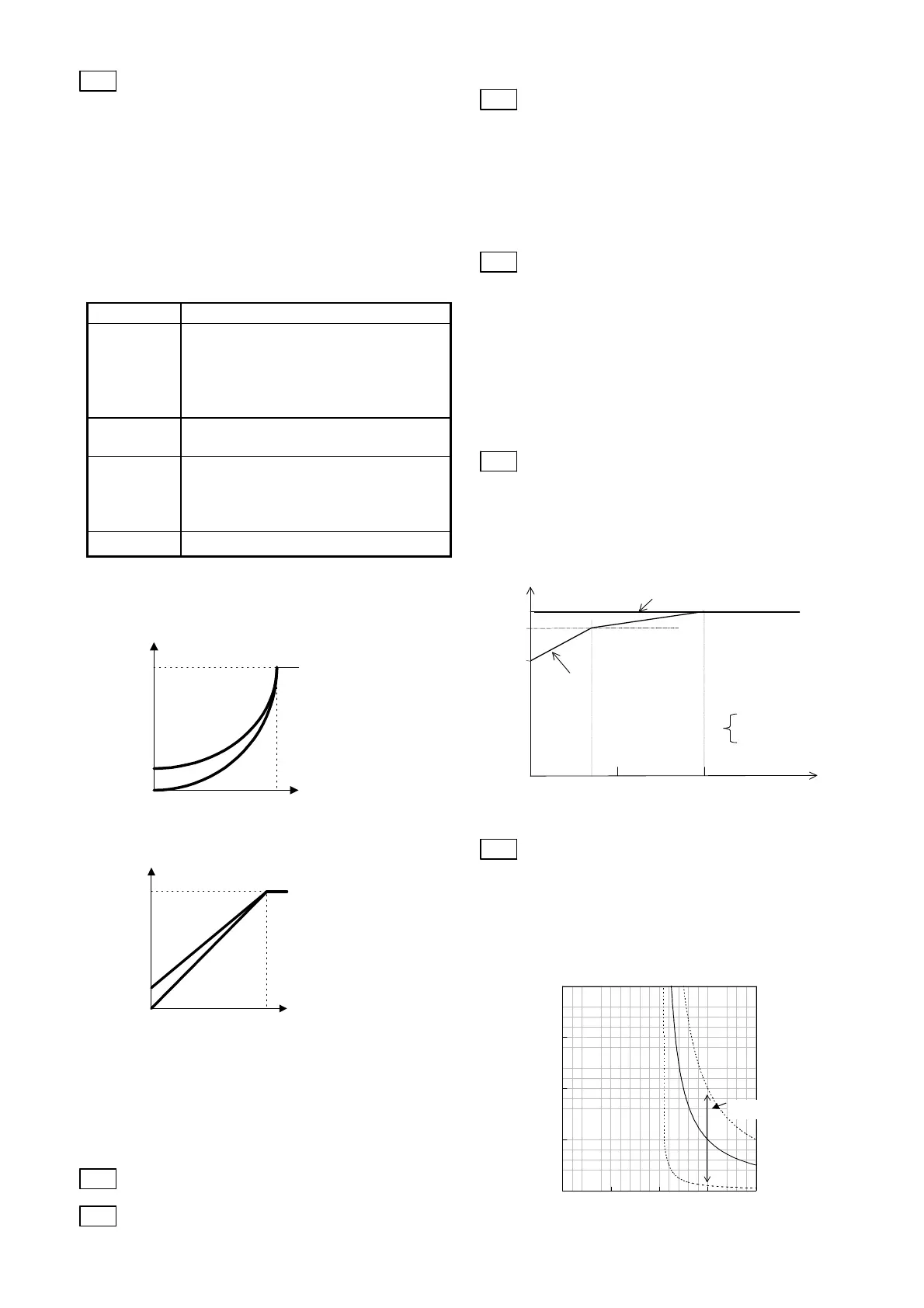

Torque characteristics

<Square reduction torque characteristics>

<Proportional torque characteristics>

100%

Output frequency f

Base

frequency 1

1

2

0

Rated voltage 1

Output voltage V

<Constant torque characteristics>

100%

Output frequency f

Base

frequency 1

3

31

0

19%

Rated voltage 1

Output voltage V

Note) When the torque boost value is excessively

large, the motor is excessively excited in the

low speed zone at all types of characteristics.

If operation continues in such a state, the

motor may be overheated. Set a value

according to the characteristics of the driven

motor.

F10

Electronic thermal overload relay 1

(Select)

F11 Electronic thermal overload relay 1

(Level)

F12

Electronic thermal overload relay 1

(Thermal time constant)

The electronic thermal overload relay watches the

output frequency, output current and operation

time of the inverter to prevent the motor from

overheat. The protective function becomes active

when 150% of the set amperage flows for the time

set at F12 (thermal time constant).

F10

Selection between active and inactive operation of

the electronic thermal overload relay and selection

of the target motor are made. When the general

purpose motor is selected, the operation level is

low at low revolution speeds according to the

cooling characteristics of the motor.

Setting: 0 Inactive

1 Active (for general purpose motor)

2 Active (for forced-ventilated motor)

F11

The operation level of the electronic thermal

overload relay is set in amperage. Enter the

value 1.0 to 1.1 times rated current of the motor.

The setting range is 20 to 135% of the rated

inverter current.

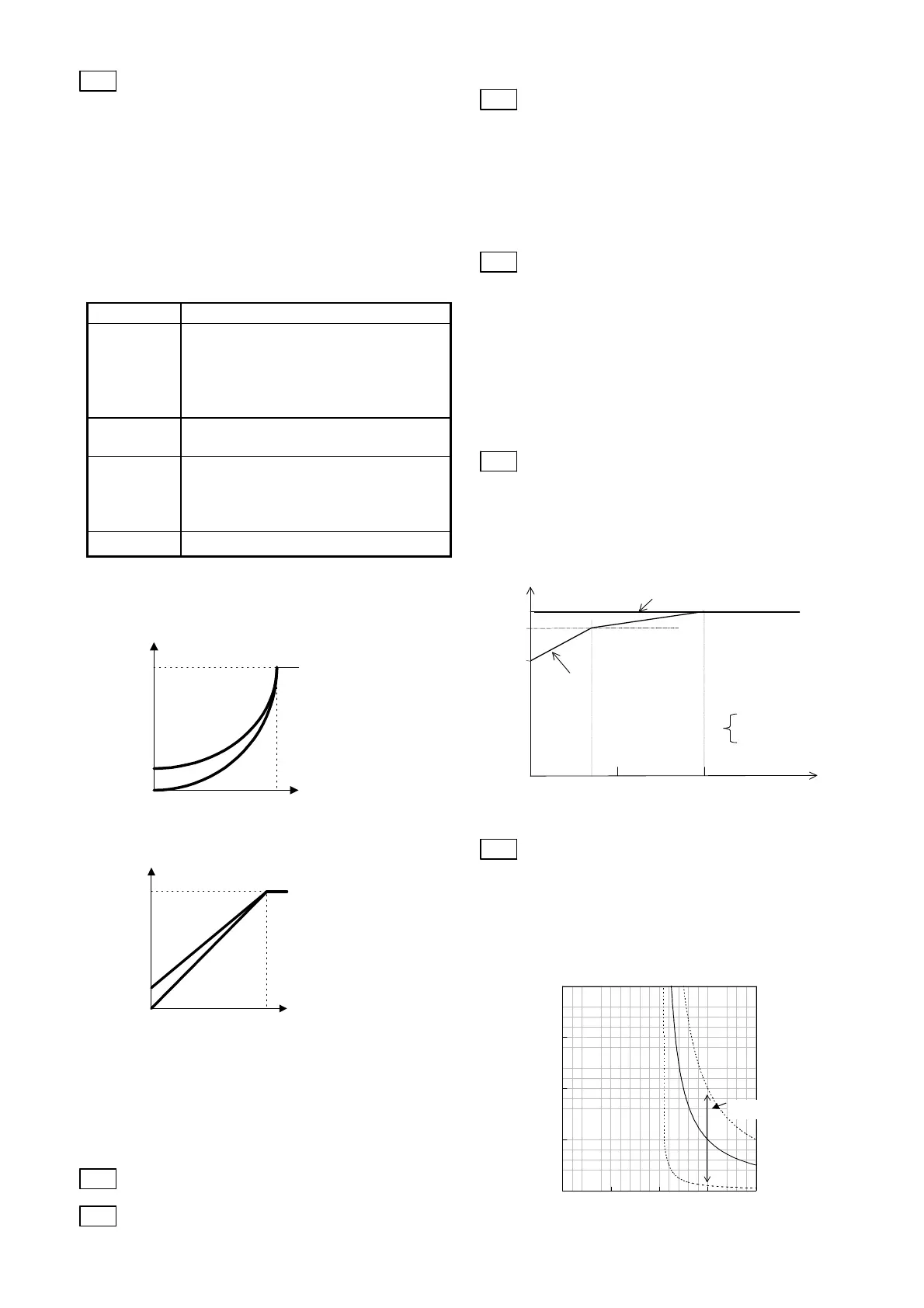

Output frequency f0 (Hz)

fe×0.33

fe

100

When F10 is 2

(%)

(When F10 is 1)

Graph of relationship between operation

level current and output frequency

fe= fb (fb<60Hz)

60Hz (fb≧60Hz)

fb: Base frequency

F12

Set the time since 150% of the operation level

current flows continuously until the electronic

thermal overload relay functions.

Setting range: 0.5 to 10.0 min.

Typical current - operation time

characteristics

0

5

10

15

20

0 50 100 150 200

Operation time (min.)

F12=0.5

F12=10

F12=5

Set by F12

((O utp ut current) / (O peration le vel current)) x 100 (%)

Loading...

Loading...