- 7 -

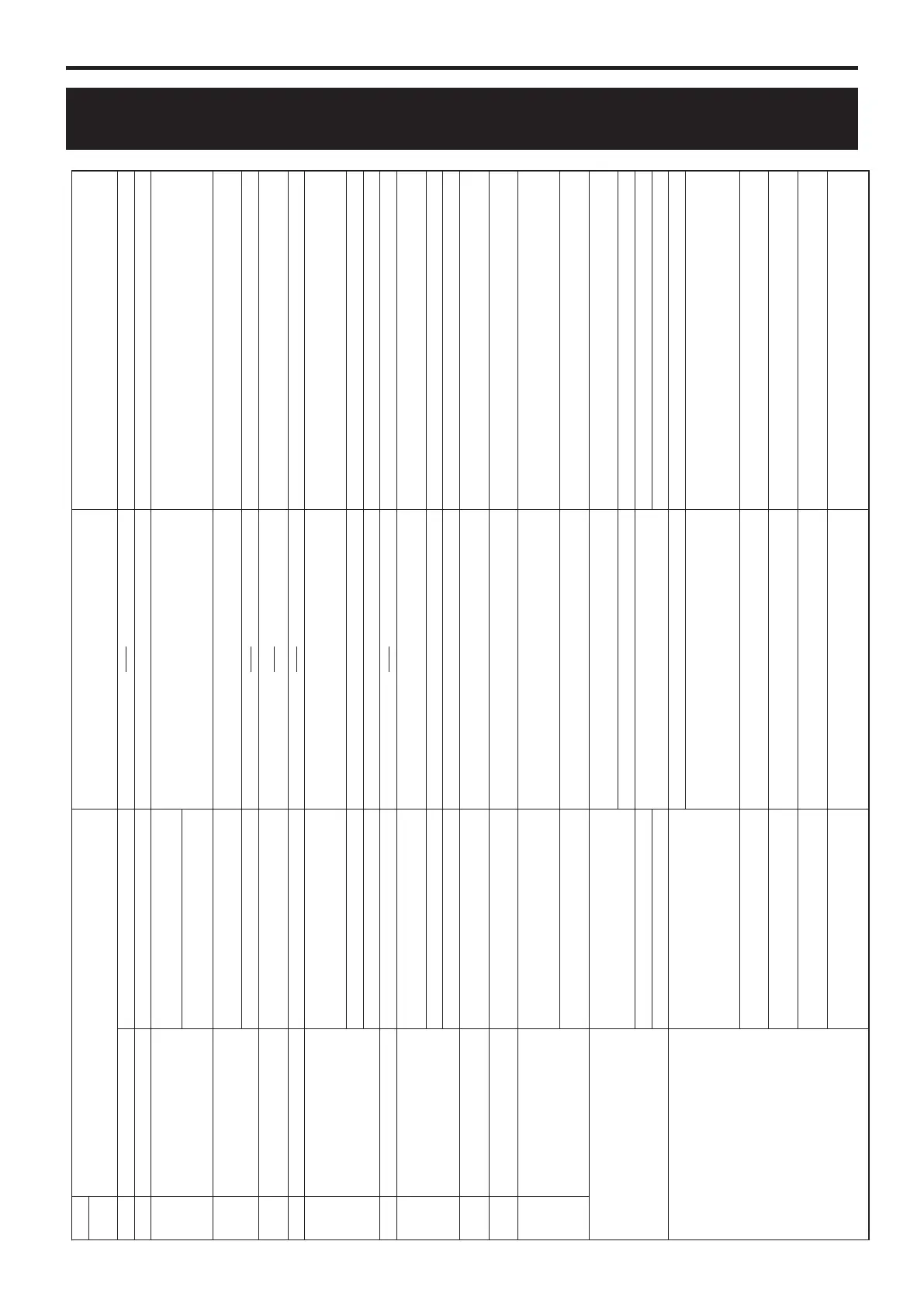

ERROR CODES

TROUBLESHOOTING GUIDE

UNIT

APPEARANCE, PORTION, PARTS SEEMED WRONG METHOD OF CHECK TROUBLESHOOTING

ERROR

CODES

C0 PCB (CONTROLLER) Error PCB (CONTROLLER) PCB(CONTROLLER) should be replaced.

C2 Outdoor temp. sensor Error SENSOR, TEMP. OUTDOOR check the resistance by tester. [see table 1] if the sensor is faulty, it should be replaced.

C3 Fan motor Error

FAN MOTOR

check the voltage of FAN MOTOR

.

[see g. 2]

check the voltage of FAN MOTOR. [see g. 2]

if the voltage is normal, FAN MOTOR should be replaced.

if the voltage is faulty, PCB(CONTROLLER) should be replaced.

PCB (CONTROLLER)

C4

rise of temperature of PCB

(CONTROLLER)

MIS-INSTALLATION

check the place of installation (blockage of air inlet &

outlet).

ensure the installation position to avoid blockage of air inlet &

outlet.

SENSOR, TEMP. PCB (CONTROLLER) PCB(CONTROLLER) should be replaced.

C5

PCB (CONTROLLER) sensor

Error

SENSOR, TEMP. PCB (CONTROLLER) PCB(CONTROLLER) should be replaced.

C6 PCB (CONTROLLER) Error PCB (CONTROLLER) PCB(CONTROLLER) should be replaced.

C7 I/F PCB serial error

MIS-WIRING [ PCB (CONTROLLER ) - I/

F PCB CONNECTING CABLE ] OR RARE

CONTACT

check the wiring connection and rare contact. after correcting mis wiring, restart operation.

I/F PCB other than described above. I/F PCB should be replaced.

PCB (CONTROLLER) other than described above. PCB(CONTROLLER) should be replaced.

C8 PCB (CONTROLLER) error PCB(CONTROLLER) PCB(CONTROLLER) should be replaced.

CC

Heat pump regulator PCB se-

rial error

MIS-WIRING (I/F PCB-HEAT PUMP REGU-

LATOR) OR RARE CONTACT

check the wiring connection and rare contact. after correcting mis wiring, restart operation.

I/F PCB other than described above. I/F PCB should be replaced.

Heat pump regulator other than described above. PCB(CONTROLLER) should be replaced.

E4

Outgoing circulating temp.

sensor Error

SENSOR, TEMP. OUTGOING CIRCULATING

WATER

check the resistance by tester. [see table 3] if the sensor is faulty, it should be replaced.

E5

Return circulating water temp.

sensor Error

SENSOR, TEMP. RETURN CIRCULATING

WATER

check the resistance by tester. [see table 3] if the sensor is faulty, it should be replaced.

P1 Pump Error

PUMP or PCB (CONTROLLER) check the voltage of PUMP. [see g. 3]

if the voltage is normal, PUMP should be replaced.

if the voltage is abnormal, PCB(CONTROLLER) should be re-

placed.

CLOGGED THE CIRCULATION PUMP AND/

OR HEATING CIECUIT

check the pump and heating circuit. remove the clog, then restart operation.

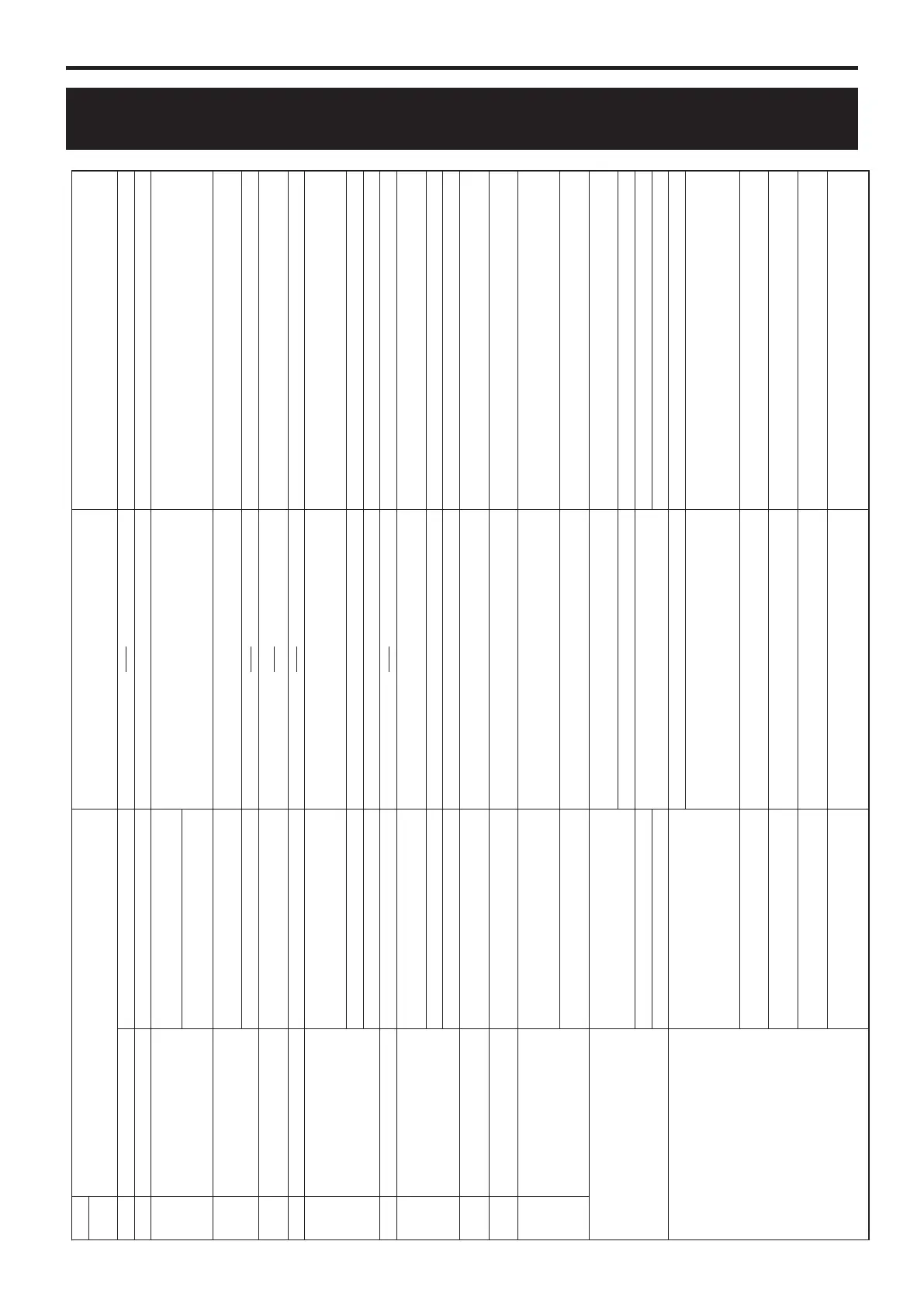

PCB (DISPLAY) cannot be operated

PCB (DISPLAY) does not display any-

thing

Lead wire of PCB(DISPLAY)

check lead wires are connected to the connectors prop-

erly.

connect the connectors to both PCB (DISPLAY) and PCB (CON-

TROLLER) steadily.

ensure that there is no disconnection for the lead wires. lead wires should be replaced.

PCB(DISPLAY)

other than described above.

PCB(DISPLAY) should be replaced.

PCB(CONTROLLER) PCB(CONTROLLER) should be replaced.

not cool down

not warm up

4-WAY VALVE

check the resistance by tester. [see g. 4] if the value is abnormal, the coil should be replaced.

energization during cooling operation is 230V.

if there is no energization, check the electric continuity

of FUSE CF2. [see g.1]

if there is no electric continuity for FUSE CF2, it should be re-

placed.

if there is electric continuity for FUSE CF2, PCB(CONTROLLER)

should be replaced.

SHORT CYCLE (INSUFFICIENT AIR CIRCU-

LATION)

check the blockage of air inlet & outlet.

ensure the installation position to avoid blockage of air inlet &

outlet.

SENSOR,TEMP. OUTGOING AND RETURN

CIRCULATING WATER

check the resistance by tester. [see table 3] if any of these sensors is faulty, it should be replaced.

GAS LEAKAGE check the service valve and refrigerant circuit (pipe).

after xing the leakage point, collect the refrigerant once, then

recharge with prescribed mass.

CLOGGED HEATING CIRCUIT

check temperature dierence heating ow/return. [see

page 15]

large dierence means ow rate is too low.

remove the clog, then restart operation.

Loading...

Loading...