FT-C Vertical Electric Thermal Fluid Heater Manual 12 2013 ISSUE 1

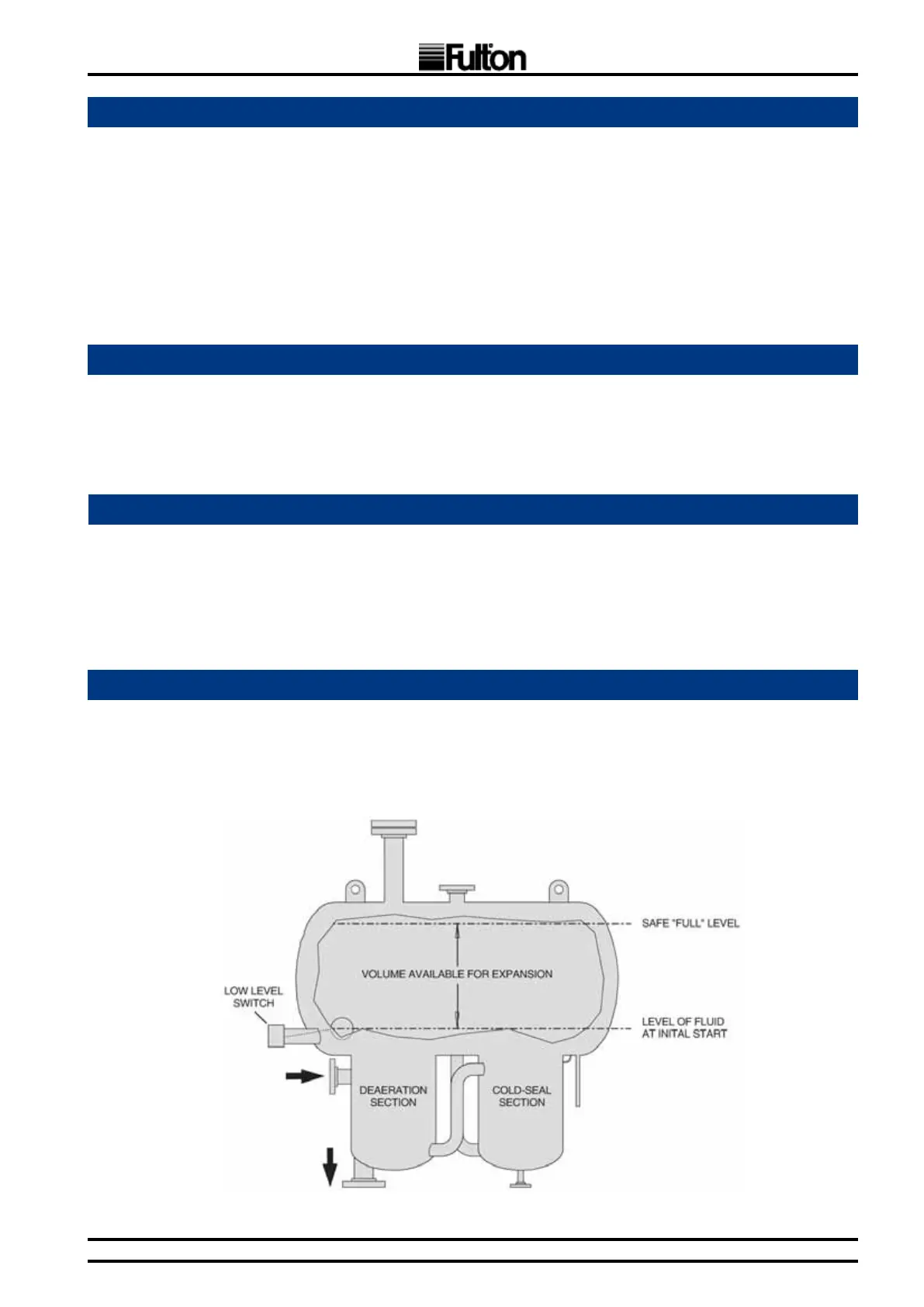

Fulton Ltd's efcient design combines the operation of the expansion, deaerator, and thermal buffer

tanks. Installation is considerably simplied by virtue of this arrangement.

The tank will be constructed of carbon steel. It shall be supplied with expansion section liquid level

switch and PN16 anged connections.

The tank may be built to BS EN 13445: 2009 upon request. Non-coded tanks should not be

pressurised above 0.5 barg.

The expansion section is vital to the thermal uid system. From ambient to operating temperature,

the thermal uid in the system will typically expand in the range of 25%-50%, and a vessel capable

of handling this expansion is mandatory. The customer should conrm the expansion rate of the

chosen uid and system volume.

At start up the primary purpose of the deaerator section is to remove all volatiles from the system to

avoid pump cavitation. The deaerator section also allows oxygen to be vented from the system on a

continuous basis during operation to avoid oxidation of the thermal uid, and removes other volatile

particles generated by the uid itself during system operation. This section of the tank should be

insulated.

A system of interconnecting pipe work in the thermal buffer tank section prevents the movement of

any oil that has not cooled sufciently into the expansion section. This avoids contact of very high

thermal uid temperature with oxygen contained in the atmosphere, which causes uid breakdown.

DO NOT insulate this section.

Please see

Loading...

Loading...