13-8-621 Page 34

12. Install the minimum pressure/check valve assembly and tighten the bolts alternately for even

tightness.

13. Open the air service valve.

14. Run the unit and check for leaks.

COMPRESSOR OIL SYSTEM CHECK - The following readings are based on ambient temperature of

80° F (27° C) with the system in good condition. The compressor should be at operating temperature at

the time of the checks. One-half hour of loaded operation is usually sufficient to reach level-out

operating temperatures.

Air and Oil Discharge Temperature - 160° F to 180° F (71°C to 82° C) - Check with a thermometer at

the discharge housing.

Compressor Oil Inlet Temperature - 150° F to 165° F (66° C to 74° C) - Install a tee at the oil filter outlet

and check with a thermometer.

Oil Inlet Pressure - Check at the fitting in the line near the compressor oil inlet. With air receiver

pressure at 100 psi (6.9 Bar), oil inlet pressure should be 80 to 90 psig (5.5 to 6.2 Bar).

Oil Cooler Oil Pressure Differential (Air-Cooled Radiator) - Check differential across the oil system by

measuring oil inlet pressure as described above.

Oil Cooler Temperature Differential (Air-Cooled Radiator) - The oil temperature differential depends

on the temperature of the air at the oil cooler fan and cleanliness of the core faces. As ambient

temperatures and core restrictions increase, the oil cooler outlet temperature will increase. The oil inlet

temperature is approximately the same as the air discharge temperature.

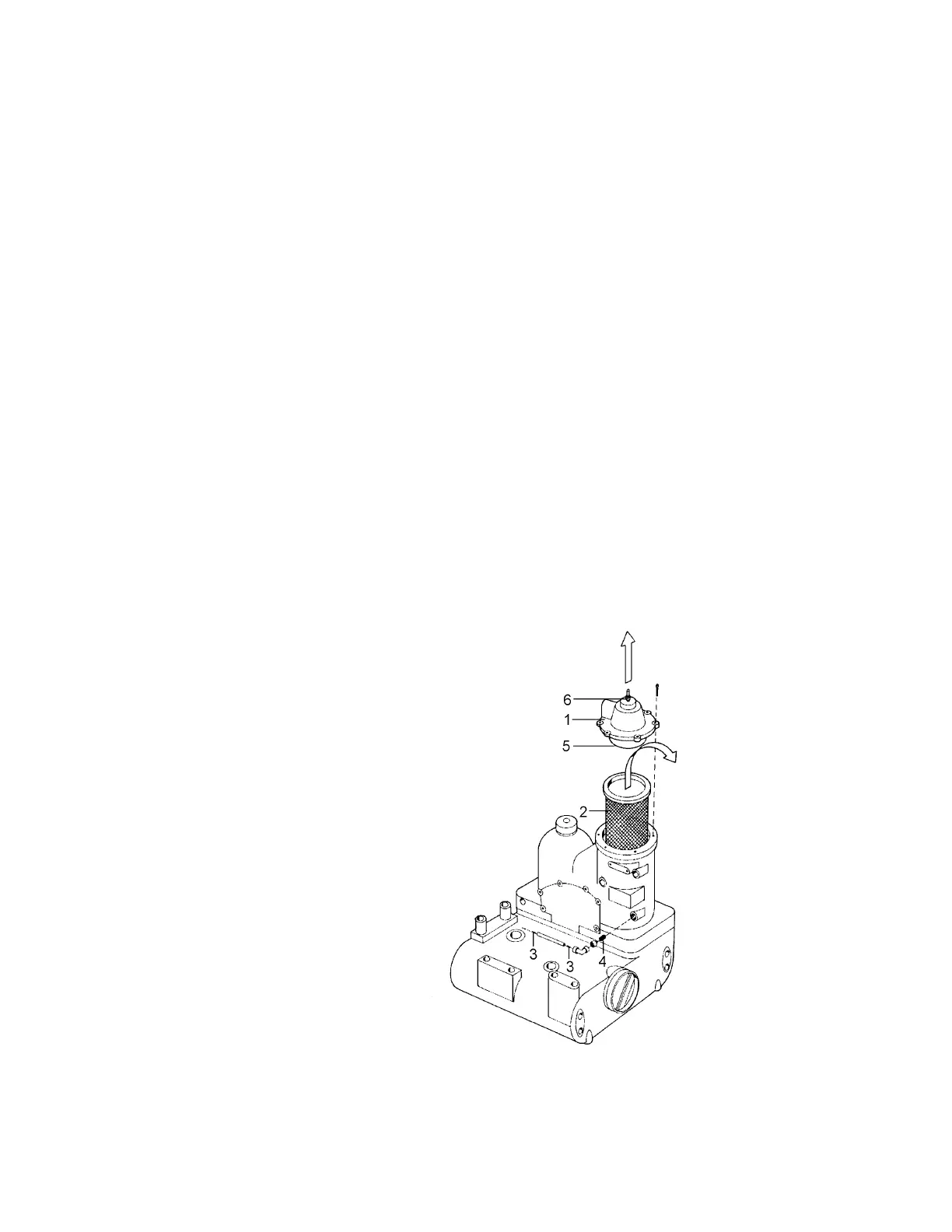

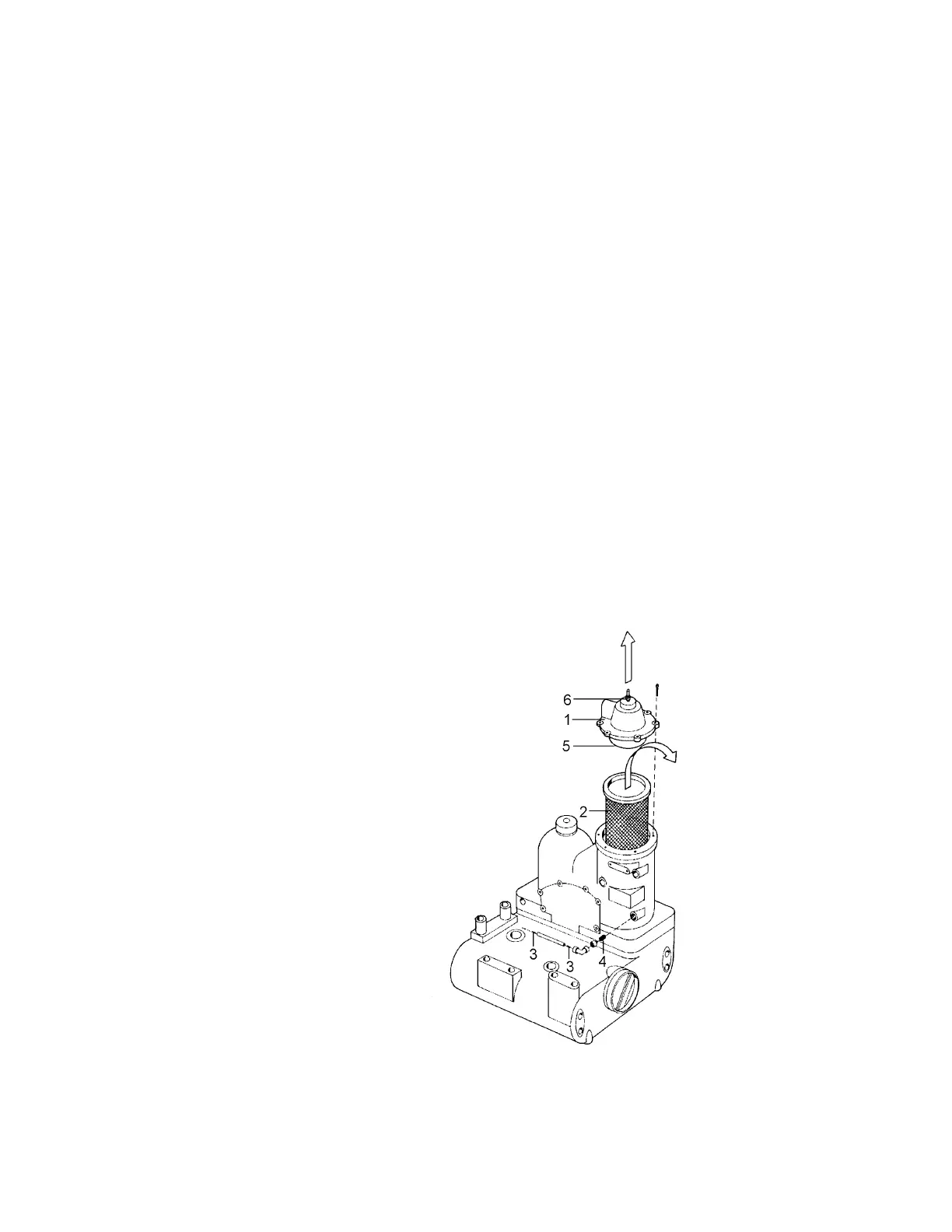

Figure 5-6 – OIL SEPARATOR

Ref.

No. Description

1 Minimum Pressure/Check Valve

2 Air/Oil Separator Element

3 Oil Scavenge Line Orifices

4 Oil Scavenge Line Strainer

5 O-Ring

6 Minimum Pressure/Check Valve

Adjusting Nut

Loading...

Loading...