Low Voltage Power Circuit

Breakers

GEK-7303

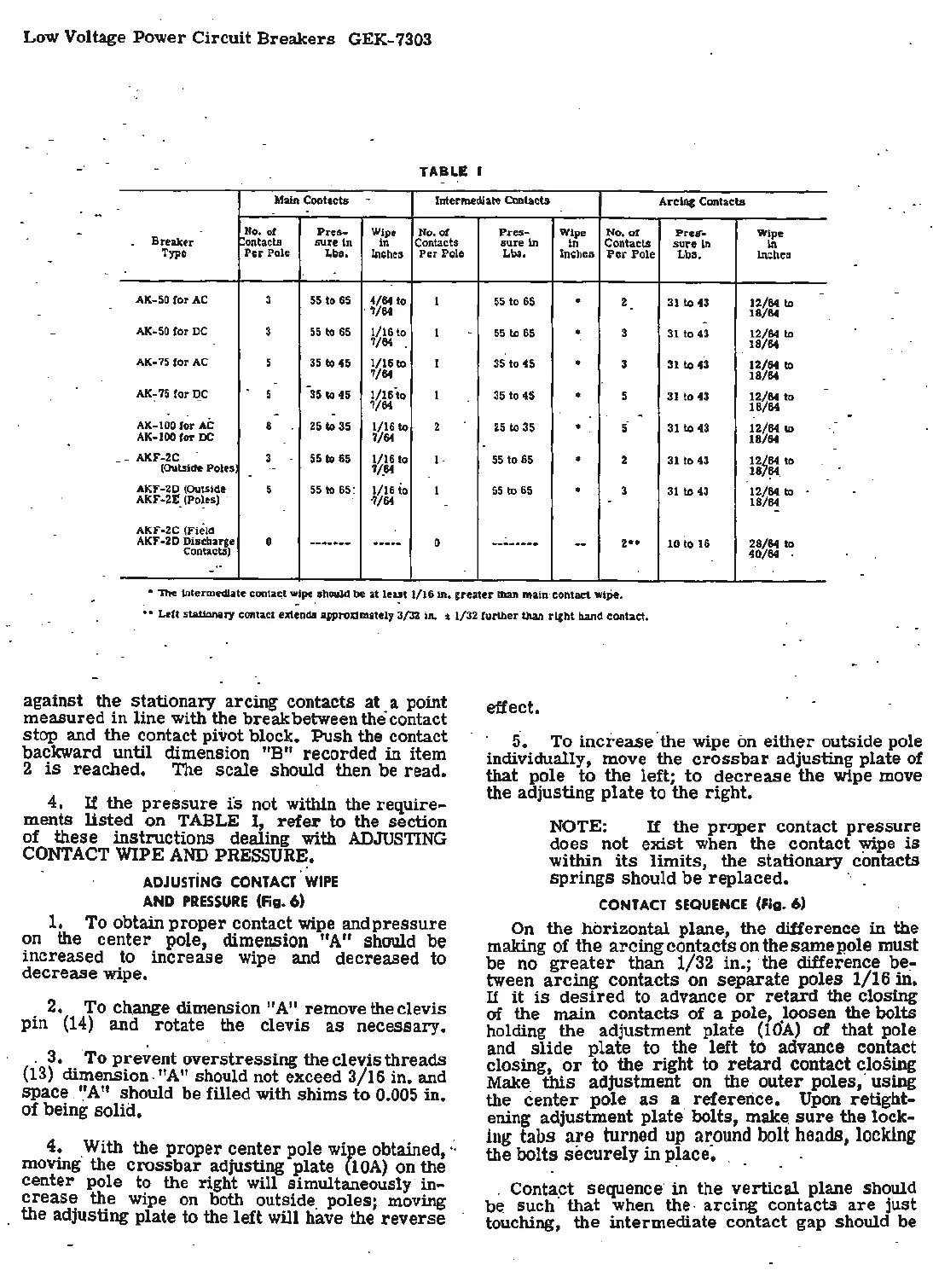

TABLE

Main Contacts - Intermediate Contacts

Arcing Contacts

No.

or

Pres-

Wipe

No.

of

Pres-

Wipe No.

of

Pre=r-

Wipe

Breaker ontacts

sure

In In

Contacts

sure

In

ln Contacts

sure

In

Ill

Type

Per

Pole

Lba,

Inches

Per

Pole Lbs,

Inches

Per

Pole

Lb

s,

lnches

-

AK-SO

tor

AC

3 55

to

65

4/64 to

1 55 to

65

.

2 31 to 43

12/64 to

. '1/64

18/64

-

AK-SO

tor

DC

3

55

to

65

1/16 to

'1/64 .

1

55 to

65

'

•

3

31

to

43 12/64 to

18/64

AK-75

tor

AC

5 35 to

45

1/16 to

7/64

1

35 to 45

.

3

31

to

43 12/64 to

18/64

-

"

35

to

45

1/16

to

12/64

to

-

AK-75

tor

DC

5

I 35

to

45

•

5

31

to

43

?/64

18/64

-

.

-

AK-I

00

for

AC

8

25

to

35

1/16 to

2

25

to 35

•

5·

31

to

43

12/64

to

AK

-100

tor

DC

?/64

18/64

_ AKF-2C

3 55 to

65

1/16 to

.

1,

55

to

65

•

2 31

to

43

12/64

to

-

(Oulside Poles

.•.

'1/.

64

.

187?4.

.

AKF-2D (Outside

5 55 to 65:.

1/16 io

I

55

to

65

• ·

3

31

to

43

12/64 to

AKF-2£' (Poles)

·:

'1/64

.

.

18/64

-

AKF•2C (Field

AKF-2D Discbarge

0

-------

-----

Contacta)

0

-----··--

--

2

..

10

io

16

28/64

to

40/64

..

-

• The intermediate conta~t

wipe

should be

at

le~t

1/16

in.

greater

than main·contact wipe.

~

•

Ldt

stationary contact ext;nda approximately 3/32 in.

~

1/32 further than right band contact.

against the stationary arcing contacts at . a point

measured

in

line with the breakbetweenthecontact

stop and the contact pivot block. Push the contact

backward until dimension ."B" ·recorded in item

2

is

reached. The

scale

should then be read.

4.

If

the

pressure

is

not within the

require-

ments

listed

on TABLE

I,

refer

to

the section

of these instructions dealing with

ADJUSTING

CONTACT

WIPE

AND

PRESSURE.

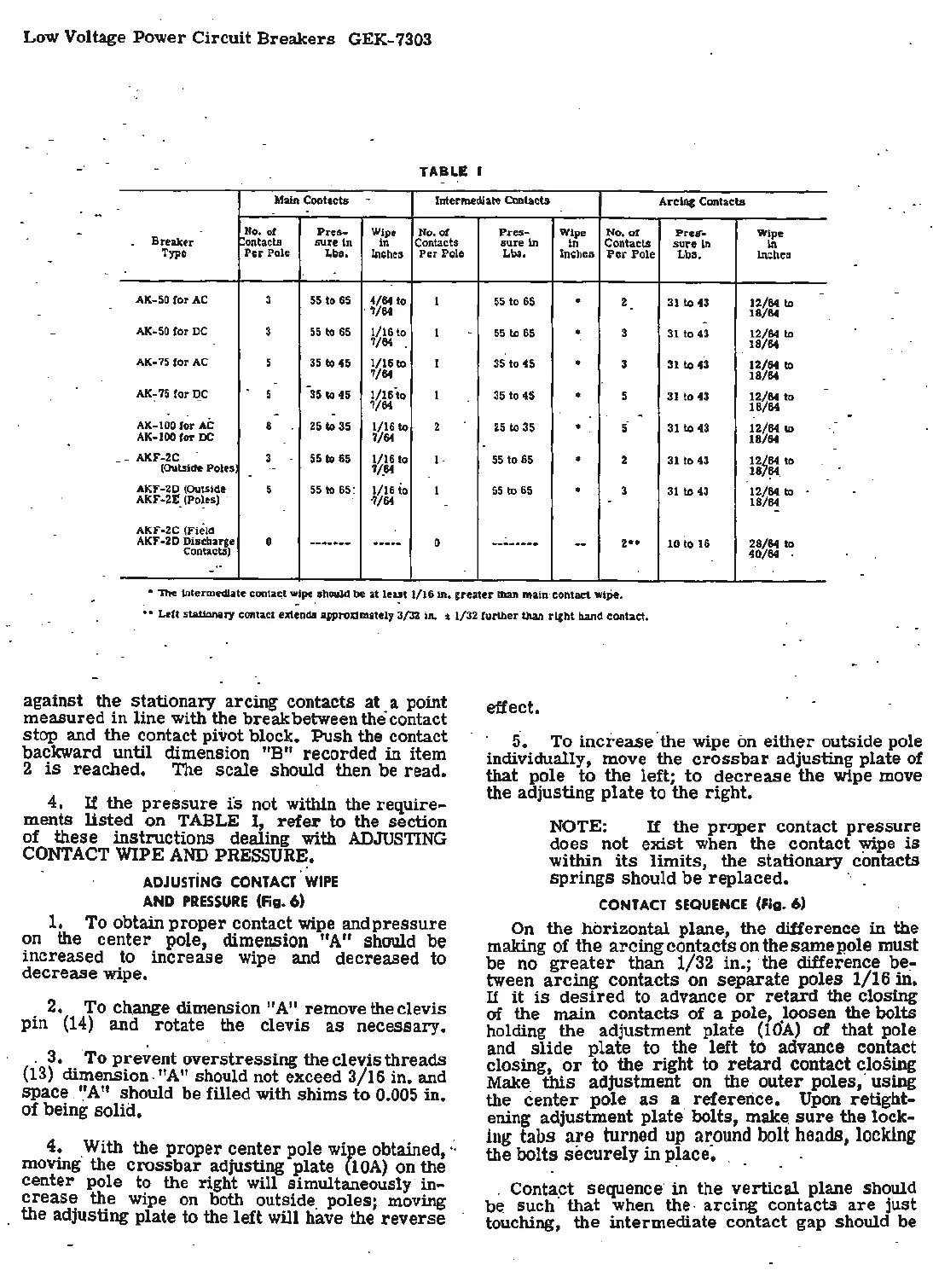

ADJUSTiNG

·coNTACT .

WIPE

AND

PRESSURE

(Fig.

6)

1. To obtain

proper

contact wipe andpressure

on the

center

pole, dimension "A" should be

increased to increase wipe and decreased to

decrease wipe.

· 2. To ch.ange dimension "A" remove the clevis

pin

(14)

and rotate the clevis

as

necessary.

. 3. . To prevent overstressing the clevis threads

(13)

dimension. "

A"

should not exceed 3/16 in. and

space.

'.'A"

should

be

filled with shims to 0.005 in.

of being solid.

·

4.

With the proper

center

pole

WiJ>e

obtained,:.

moving·

the

crossbar

adjusting plate

{lOA)

on the

center pole to the right will simultaneously

in-

cre

a

se

the wipe on both outside. poles; moving

the adjusting plate to the left will have the

reverse

effect.

5.

To

increase

·the wipe on

either

outside pole

individually, move the

crossbar

adjustin~ plate of

that

pole

to

the

left;

to

decrease

the wipe move

the adjusting

plate

to

the

right.

NOTE:

If

the

proper

contact

pressure

does not

exist

when

the

contact

y.,ipe

is

within

its

limits,

the

stationary contacts

springs

should be replaced. ·.

CONTACT

SEQUENCE

(Fig. 6)

On

the

horizontal plane,

the

difference in the

making

of the arcing contacts

on

the same pole must

be

no

greater

than 1/32 in.; the difference

~e~

tween

arcing

contacts on

separate

poles 1/16

m.

If

it

is

desired

to advance

or

retard

the closing

of the main contacts of a pole .loosen the bolts

holding the adjustment plate

(10A)

of

that pole

and

slide

plate

to

the left to advance

con~ct

closing,

or

to

the right to

retard

contact

~los~g

Make

this

adjustment on the

outer

poles, usmg

the

center

pole

as

a reference.

Upon

retight-

ening adjustment plate· bolts,

make.

sure

the lock-

ing

tabs

are

turned

up

a:r:ound

bolt

heads,

locking

the bolts

securely

in

p~ace. . . .

. Contact sequence·

in

the

vertical

plane should

be such·

that

when the. arcing contacts

are

just

touching,

the

intermediate contact gap should be

Loading...

Loading...