ÄKTA start Maintenance Cue Card, 29-0240-43 AC 10

Cleaning the Fraction collector

Maintenance interval

Clean the Fraction collector when required, for example in

case of liquid spill in the Bowl assembly.

Required solutions

Water

20% ethanol

Cleaning cloth

•

•

•

Note: The inlet lters are mounted on the inlet tubing at the

ending that will be immersed in the buer solution.

Replace the inlet lters

Note: An Inlet Filter Set containing inlet lters and support

nets is included in the accessories kit.

Instruction

Pull o the inlet lter and the support net from the inlet

lter holder.

Fit the new support net and inlet lter, and press the

lter in position into the inlet lter holder.

1.

2.

Replace the tubing and connectors

Maintenance interval

Replace tubing and connectors when the tubing is

clogged or bent so that the ow is obstructed, or when

leaking.

Note: Before starting to replace tubing and connectors,

clean the system ow path with DM water, then remove

the inlet tubing from water.

Instruction

Unscrew the connectors, and disconnect the tubing.

If the tubing has labels, remove the labels and use

them with the new tubing later. Discard the old tubing

and connectors.

Cut the new tubing to the same length as the original

tubing. Use a tubing cutter to get a straight angle cut.

Mount the connectors on the tubing.

Insert the tubing with connector into the port. Make

sure to insert the tubing all the way into the bottom of

the port.

Tighten the connector fully.

Note: To replace the Pump tubing (Part No. 29-0240-

12), follow the instructions presented in the ÄKTA start

Maintenance Manual.

1.

2.

3.

4.

5.

6.

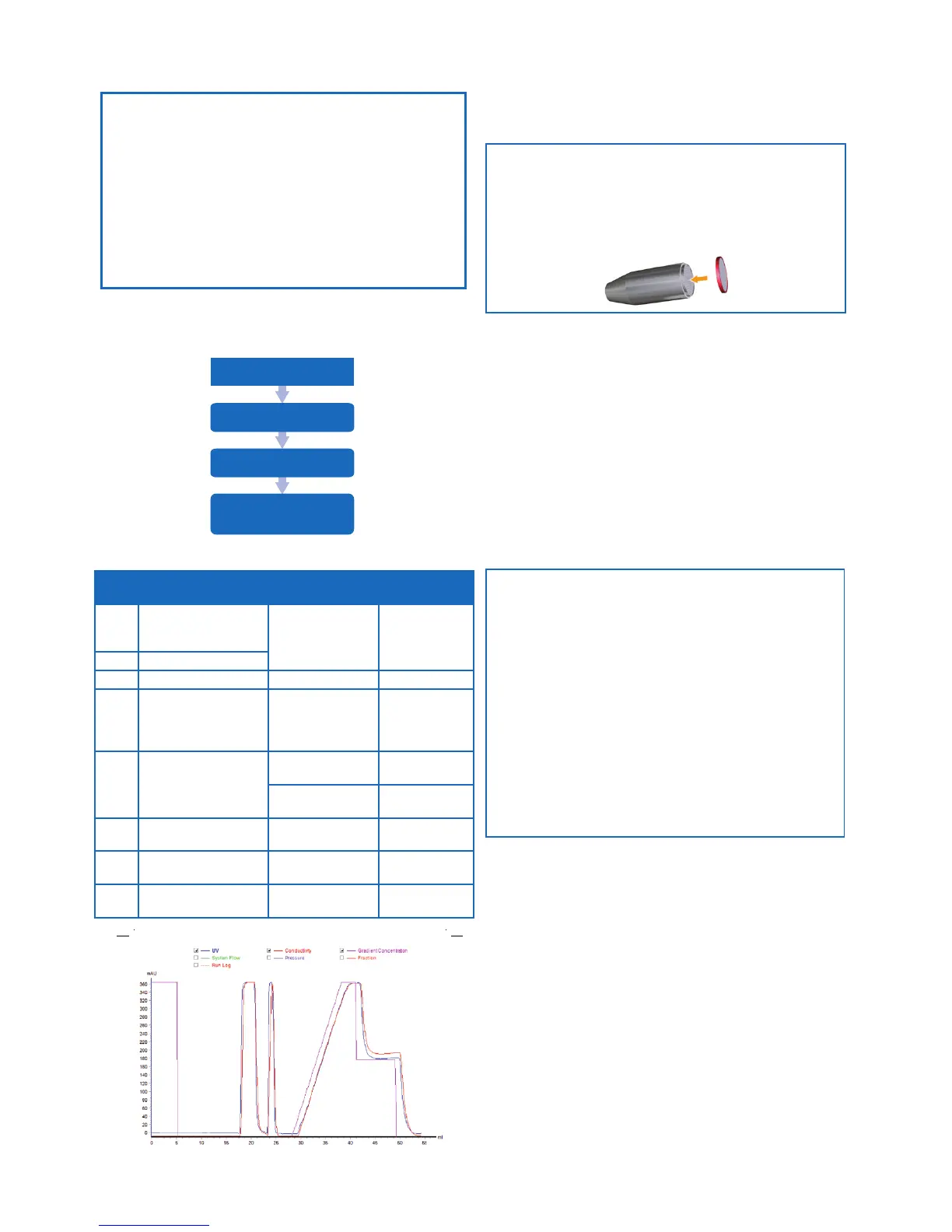

A typical System performance test result le:

Operation from UNICORN start

Instruction

Select method based on the Fraction Collector

conguration: a) Performance method with Frac: when

Fraction collector is enabled; b) Performance method

without Frac: when Fraction collector is disabled.

Read the method notes before starting the run.

Make a note of the result le location.

Run the performance method.

The test report states whether the performance test

passed or failed.

Note: Verify Pressure limits, Fractionation/collection

volumes, gradient levels and all connections for leakage

during the test, using the Acceptance criteria below.

1.

2.

3.

4.

5.

Acceptance criteria

Time

(min)

Activity Check Aproved

interval

1 1 ml/min, 0 %B, ow

through Outlet valve,

Waste position

Back pressure =< 0.05 MPa

2 Repeat UV Auto Zero

3 5 ml/min Back pressure 0.06 - 0.2 MPa

15 Start gradient,

0-100 %B in 10 min,

start fractionation/

collection

19 End fractionation

(with Fraction

collector)

Weigh fraction no

2, 3 and 4

0.8 - 1.2 g

Max di. between

fractions

0.1 g

20

End collection (with-

out Fraction collector)

Weigh beaker 4.2 - 5.8 g

25

End gradient, stay at

100 %B

Gradient (UV 50%

B / UV 100% B)

Straight, no

negative dips.

41 End Check all connec-

tions for leakage

No leakage

Loading...

Loading...