ÄKTA start Maintenance Cue Card, 29-0240-43 AC

4

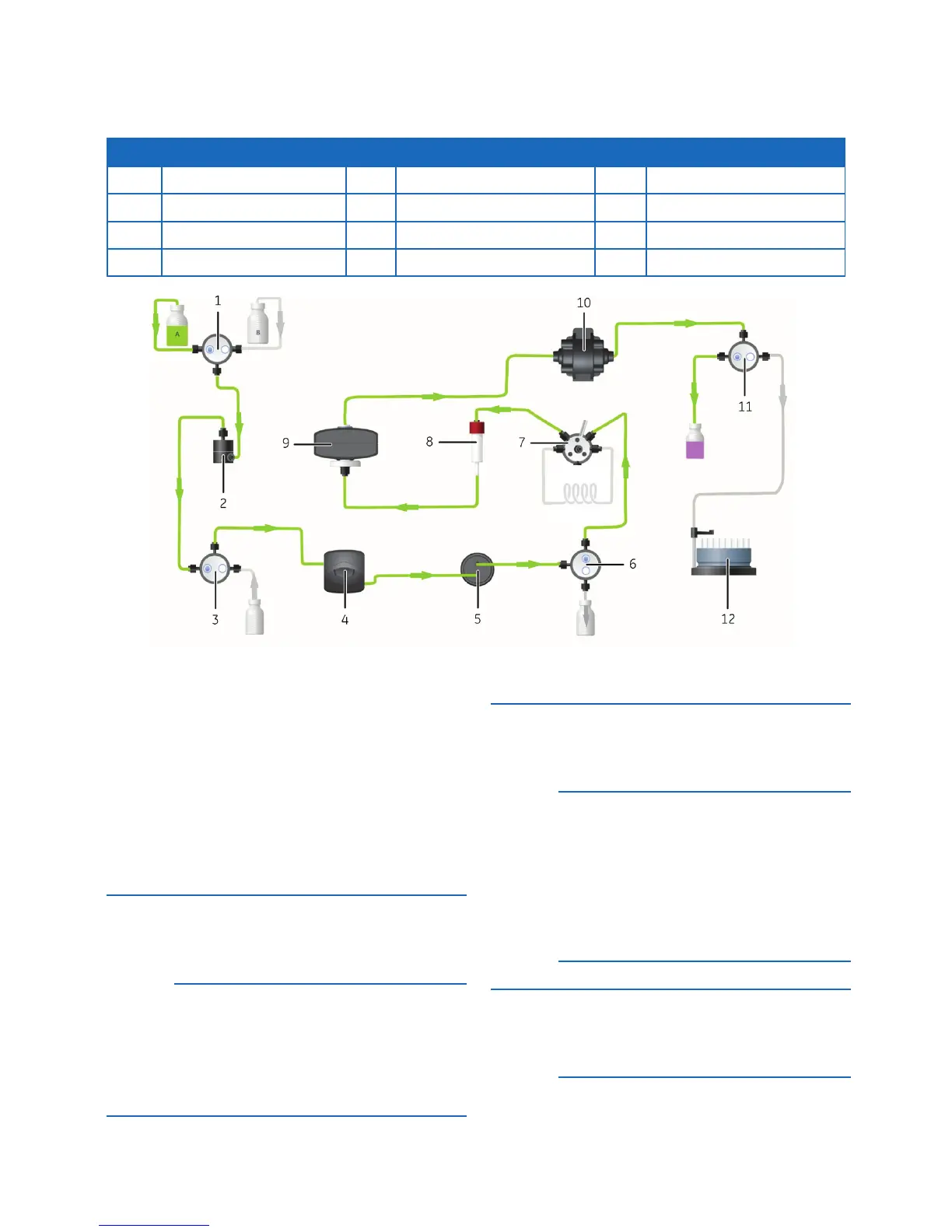

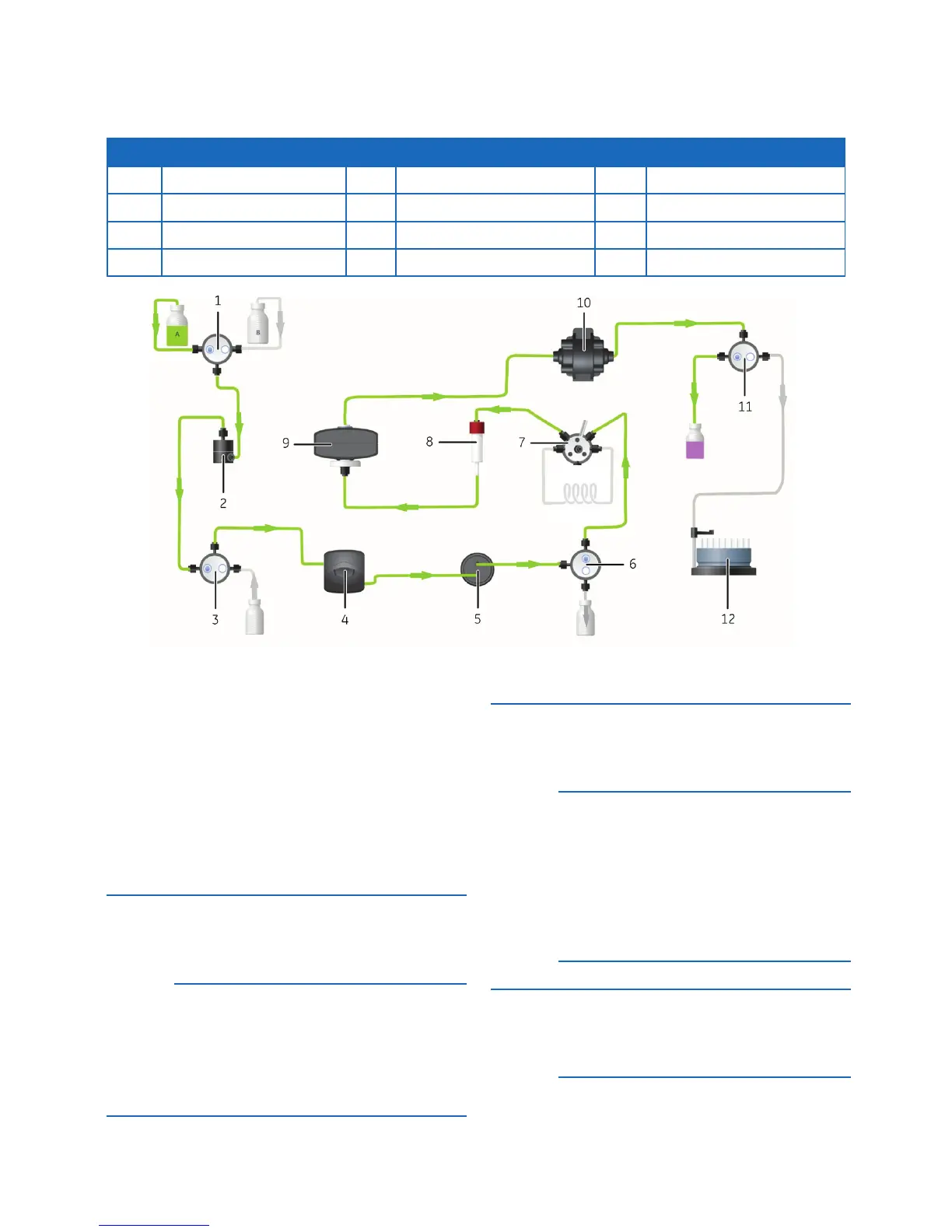

Flow path overview

The illustration below shows the ow path for ÄKTA start.

Part Description Part Description Part Description

1 Buer valve 5 Pressure sensor 9 UV Monitor

2 Mixer 6 Wash valve 10 Conductivity Monitor

3 Sample valve 7 Injection valve (manual) 11 Outlet valve

4 Pump 8 Column 12 Fraction collector

Regular maintenance

Regular maintenance is important for safe and trouble-

free operation of ÄKTA start. The user should perform

maintenance on a daily, weekly and monthly basis.

Periodic maintenance schedule

The periodic maintenance schedule provides a guide to

the user to ensure proper maintenance of the ÄKTA start

and Frac30.

Interval Maintenance action

Daily Visually inspect the instrument for leakages

in the ow path.

If there are signs of liquid leaking, check

integrity of tubing and tubing connections.

Clean the column and ow path after use

and leave the system lled with DM water.

Note: If the instrument is not going to be used

for 1-2 days, prepare the system for storage.

Note: Open the pump cover after switching

o the instrument.

Interval Maintenance action

Weekly,

or when

required

Visually inspect the inlet lters and clean

them if necessary.

Cleaning procedure: immerse and leave the

inlet lters in 1 M NaOH for about 2 hours.

Clean the system ow path with 0.5-1 M

NaOH and rinse with demineralized (DM)

water.

Note: Do not leave the system in NaOH for

more than 20 min.

Note: Cleaning may be necessary more or

less frequently, depending on the system

usage and the nature of the samples.

Calibrate the Pump.

When

required

Clean the instrument externally.

Cleaning procedure: Wipe the surface with

a damp cloth. Wipe o stains using a mild

cleaning agent or 20% ethanol.

Loading...

Loading...