FHSD700C Series Product Guide

GE Security

3.3 Connection of Sampling Tubes

There are several common guidelines that should be followed when attaching the pipe network to the

FHSD700C detector:

Pipes must NEVER be glued to the inlets of the detector

Pipe network itself MUST be glued together

Use removable unions where necessary

Unused inputs on FHSD7215DC detectors should be looped to one another using short lengths of

microbore. For example, if an FHSD7215DC has unused inputs 9 to 15, one way of connecting the

unused inputs would be to use short pieces of microbore to connect inputs 9 to 12, 10 to 13, 11 to 14

and have input 15 capped off. Ensure that these short lengths of microbore do not kink.

Do not insert ANY object into the inlet ports other than the correct size of piping. This is

to avoid damage to delicate electronic flow sensor components mounted just inside

each port opening.

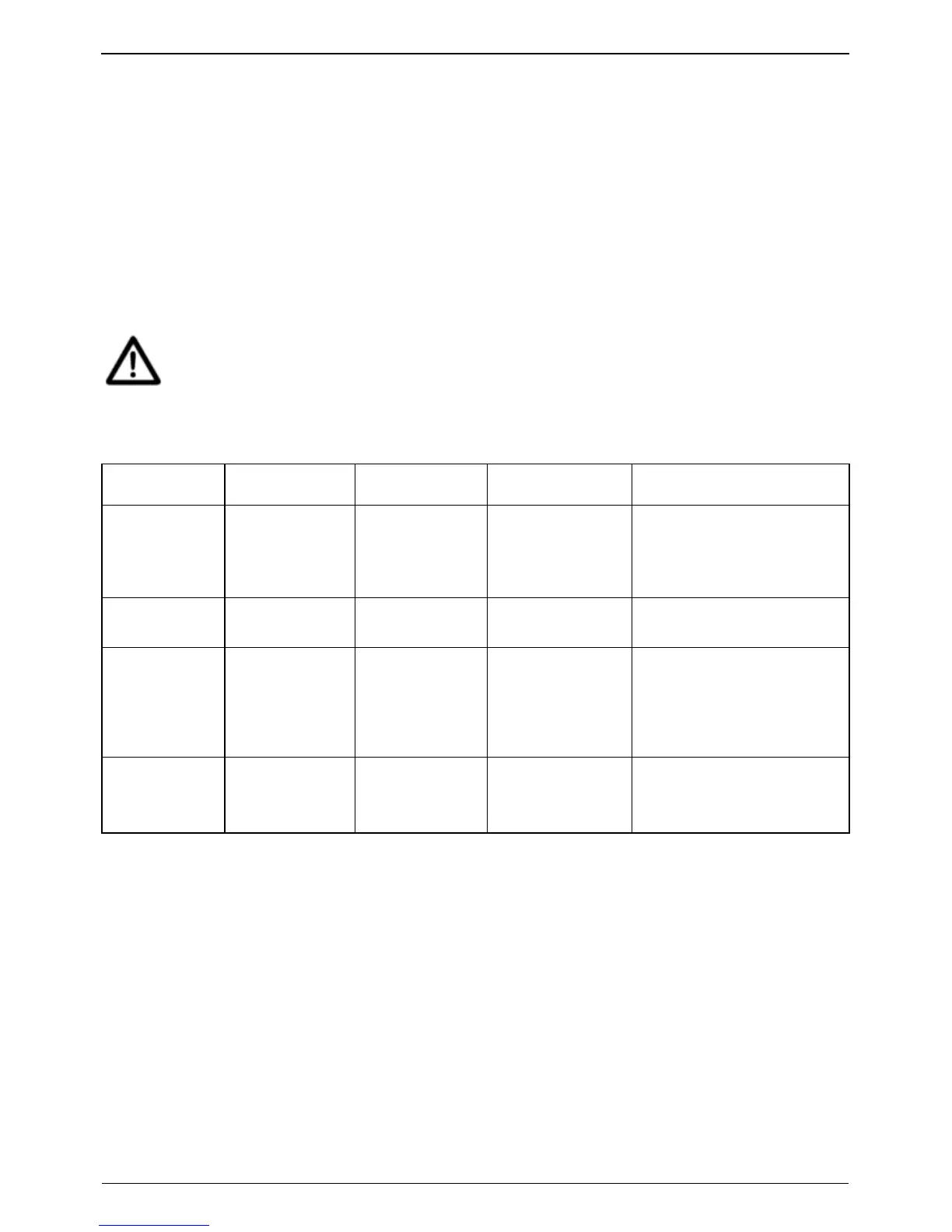

Other pipe and inlet specifications are addressed in the following table.

Table 3-6: Detector Inlet to Pipe Network Termination Specifications

Detector Inlet Port Acceptable Pipe

or Adapter

Maximum Pipe

Length

Other Considerations

FHSD720C 25mm outer-

diameter UPVC

tubes

25mm; or

26.7mm (0.75in.)

with 25 to 26.7mm

(0.75in.) adaptors

2 x 100m -

FHSD721C /

FHSD721DC

Tapered push-fit 26.7mm (0.75 in.)

to 25mm

4 x 100m -

FHSD724DC &

FHSD726DC

Tapered push-fit

25mm; or

26.7mm (0.75in.)

with 25mm to

26.7mm (0.75in.)

adaptors

4 x 100m

or 6 x 100m

-

FHSD7215DC - 6mm outer-

diameter, 4mm

inner-diameter

flexible nylon tube

50m

Note: Tube lengths

should be equal

Other materials may be used

e.g. FEP/ Stainless Steel with

suitable adaptors for harsh

environments

14

www.gesecurity.net

Loading...

Loading...