– 28 –

(Continued next page)

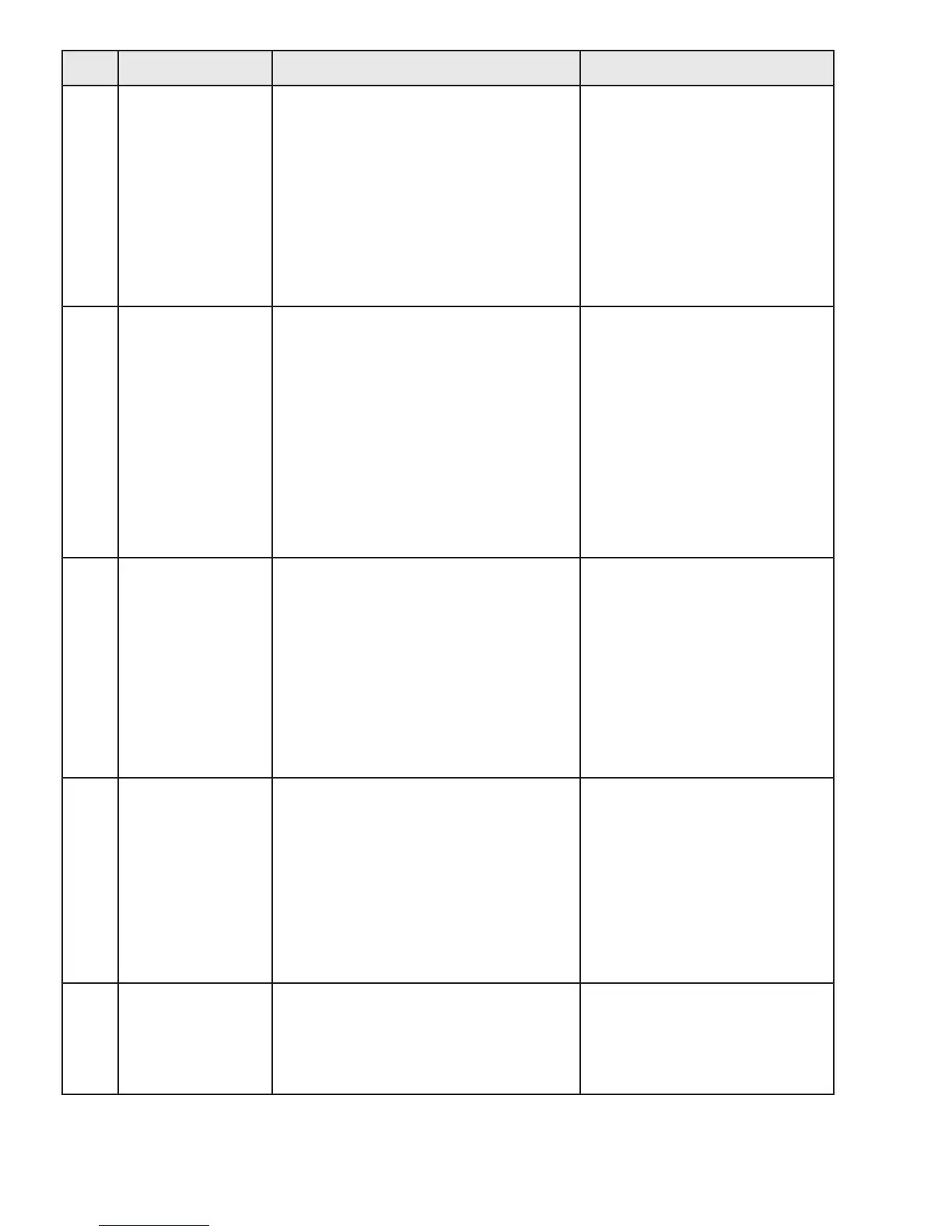

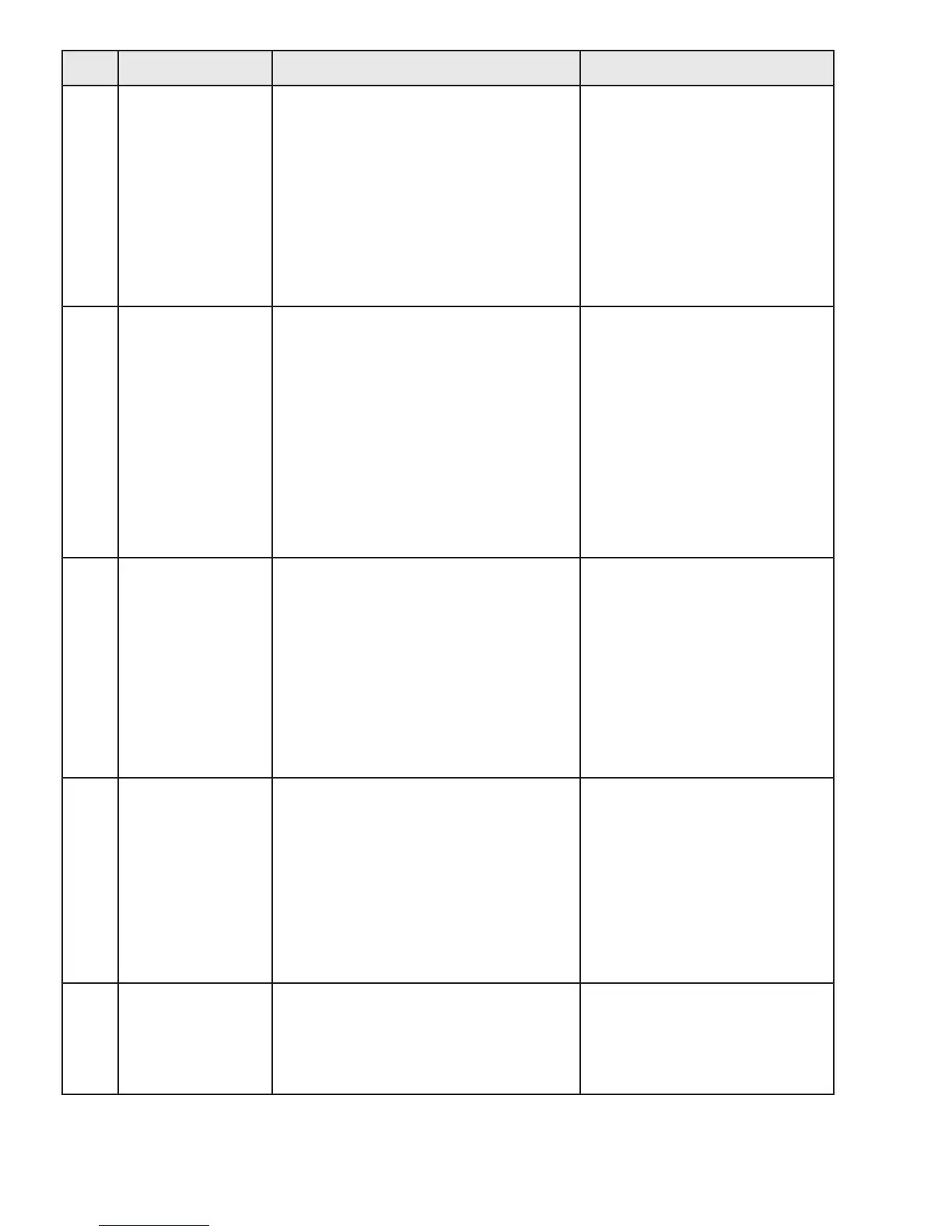

Fault

Code

Fault Name Description Repair Action

5 Mode Shifter Control didn’t see the transition from Agitate

to Spin or vice-versa in the time required.

Could mean the shift didn’t occur or Control

didn’t get the signal because of lack of

connection.

Check mode shifter coupler for

damage and the ability to slide

in and out freely.

Using an ohm meter, check to

ensure mode shifter switch is in

the open position.

Check resistance of mode

shifter motor (approximately

5.7k ohms).

Check for 120 VAC to the mode

shifter motor at the control J512

connector.

If voltage is present, replace the

mode shifter.

6 Critical Flood

Level by Pressure.

Pressure level

exceeds 17.5 inches

above pressure port.

Control received an extended period of

pressure readings that is nearing over-flow

levels. Pressure 17.5”.

Voltage output must be present. Could

mean water did get that high due to briefly

stuck water valve. Voltage output of sensor

too high for actual water level because of

sensor or water in pressure tube increasing

pressure.

Check pressure tube for

pinches where it goes through

top cover grommet.

Check pressure tube for

trapped water.

Check for any leaking water

valves.

Check the output voltage from

the pressure sensor to ensure

it matches the water level in

the basket according to the

pressure sensor chart. If it

does not, the control will need

to be replaced as the pressure

sensor is mounted directly to

the control.

7 Flood Warning

Level by Pressure.

Pressure level

exceeds 16.5 inches

above pressure port.

Main micro received and extended period

of pressure readings that is greater than

maximum allowable fill volume. Pressure

16.5”. Voltage output must be present.

Could mean water did get that high due to

briefly stuck water valve. Voltage output

of sensor too high for actual water level

because of sensor or water in pressure

tube increasing pressure.

This can happen if a large wet

load is placed in the washer.

Check pressure tube for

pinches where it goes through

top cover grommet.

Check pressure tube for

trapped water.

Check for any leaking water

valves.

Check the output voltage from

the pressure sensor to ensure

it matches the water level in

the basket according to the

pressure sensor chart.

8 Pressure Sensor

Loss

This determines if there has been a too

great of a difference in the pressure sensor

reading and the expected pressure sensor

reading for the amount of water the control

calculated it has put in. It assumes there

is a pressure leak, a clog in the pressure

hose/system delaying the increase in

pressure, or a significant amount water

leaking out.

Check house water supply

vales are turned on.

Check pressure tube for

pinches where it goes through

top cover grommet.

Check pressure tube for

trapped water.

Check water valve operation.

Check the output voltage from

the pressure sensor to ensure

it matches the water level in

the basket according to the

pressure sensor chart.

9 Lid Switch

Redundancy

Start attempted for a fourth cycle when

the previous three cycles have completed

with backup micro seeing lid open. Could

mean the switches didn’t occur or backup

processor didn’t get the signal because of

lack of connection. See Fault Code 2 as

well.

Open and close the lid to clear

the fault.

Check harness and connectors

that go to the lid switch.

If the fault will not clear, replace

the lid switch.

Loading...

Loading...