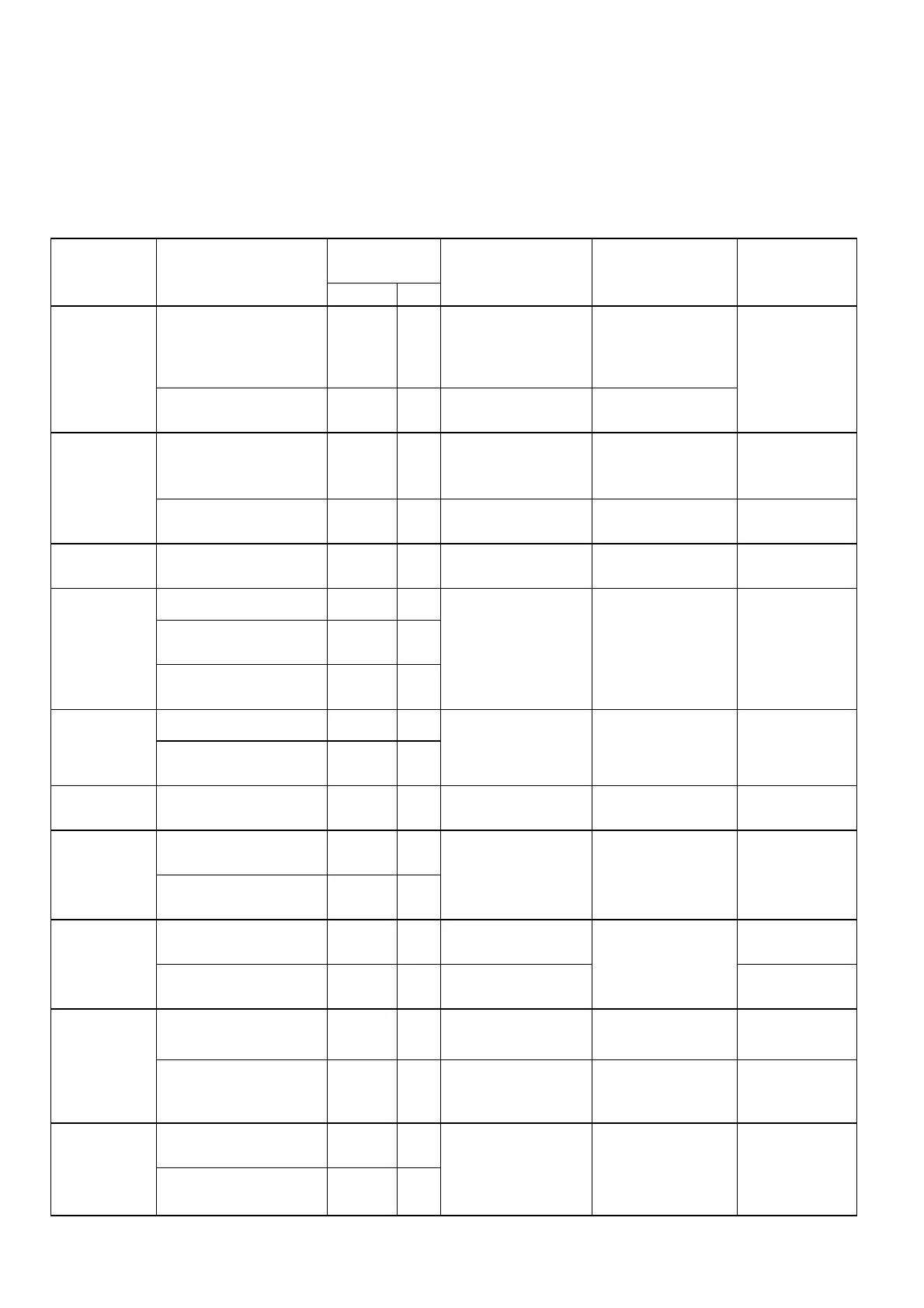

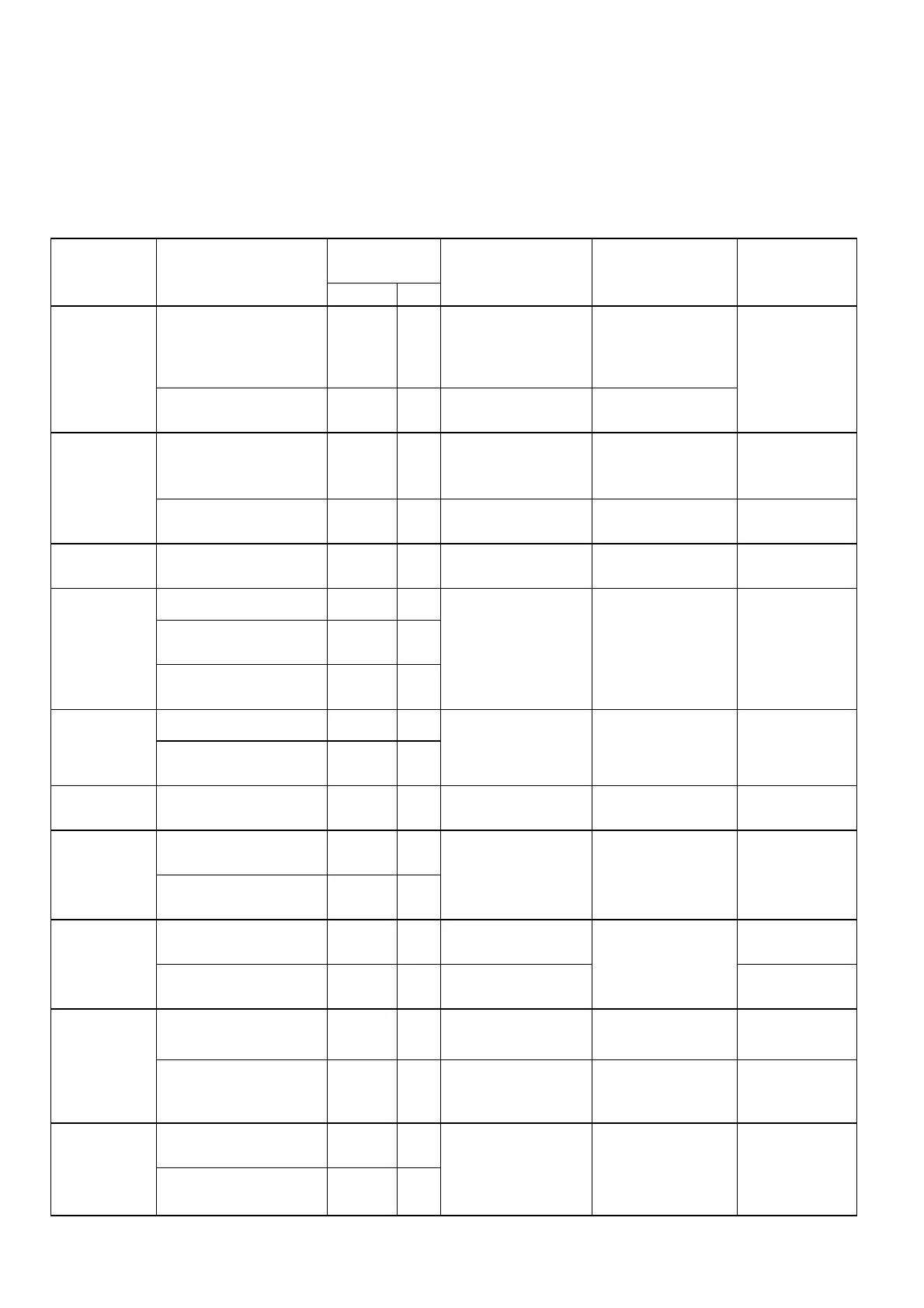

46

Routine examination and periodical examination

Inverter requires routine and periodical examination and maintenance for a more stable and safer operation.

Refer to following table for required examination item for a more stable and safer operation.

Carry out examination after the “ Power LED ” indicator goes off for 5 minutes to prevent the maintenance

personnel injury caused by the remaining charges in the capacitor of inverter.

Examination

period

Maintenance

item

Maintenance

description

Routine 1 Year

Examination

method

Criterion

Countermeasure

Reconfirm environment

temperature and humidity

°

Refer to installation

instructions and measure

with thermometer and

hygrometer

Temperature: -10~40

OC Humidity: under 95%

without condensing

Installation site

environment

Check and remove any

flammable material nearby

°

Visual inspection No foreign object

Improve installation

site environment

Is there any abnormal

vibration on the installation

site?

°

Visual and audio

inspection

No foreign object Tighten loose

screw

Inverter

Installation anf

grounding

Is the grounding resistance

within acceptable range?

°

Measure resistance by

multi-meter

200V class under 100

ohm

Improve grounding

Input power

source voltage

Is the voltage of the primary

circuitry normal?

°

Measure voltage by

multi-meter

Voltage level conforming

specification

Improve input

power source

Is the tighten parts secured?

°

Is there any sign of breakage

on the terminal panel?

°

Inverter

external

terminal

mounting

screw

Is there any obvious rusty

condition?

°

Visual inspection. Use

screwdriver to verify

screw tightness

No abnormality

Tighten loose screw

or return for repair

Is it deformed or skewed?

°

Internal wiring

of inverter

Is the insulation of wire

broken?

°

Visual inspection

No abnormality

Replace or return

for repair

Heat-sink Is it accumulating dust or

dirt?

°

Visual inspection No abnormality Clean up dust or dirt

Is it accumulating conductive

metal or oil stain?

°

PCB

Is there any over-heated or

burnt component?

°

Visual inspection

No abnormality

Clean up or replace

PCB

Is there any abnormal

vibration or noise?

°

Visual and audio

inspection

Replace cooling fan Cooling fan

Is it accumulating dust or

dirt?

°

Visual inspection

No abnormality

Clean up

Is it accumulating dust or

dirt?

°

Visual inspection No abnormality

Clean up Power

component

Examine resistance between

each terminal

°

Measure by multi-meter No short-circuit or

open-circuit on the

three-phase output

Replace power

component or

inverter

Is there any sign of strange

odor or leakage?

°

Capacitor

Is there any sign of swelling

or bulging?

°

Visual inspection

No abnormality

Replace capacitor

or inverter

Loading...

Loading...