28

D

GB

F

E

I

Ru

09790-02.2018-DGbFEIRu

7.2 Work to be carried out

7| Maintenance

In order to guarantee optimum operational reliability and service life of the compressor, we

recommend carrying out servicing and inspection work at regular intervals:

Oil change:

- not mandatory for factory-produced series systems.

- foreldinstallationsorwhenoperatingneartheapplicationlimit:forthersttimeafter100

to 200 operating hours, then approx. every 3 years or 10,000 - 12,000 operating hours.

Dispose of used oil according to the regulations; observe national regulations.

Annual checks: Oil level, leak tightness, running noises, pressures, temperatures, function of

auxiliary devices such as oil sump heater, pressure switch.

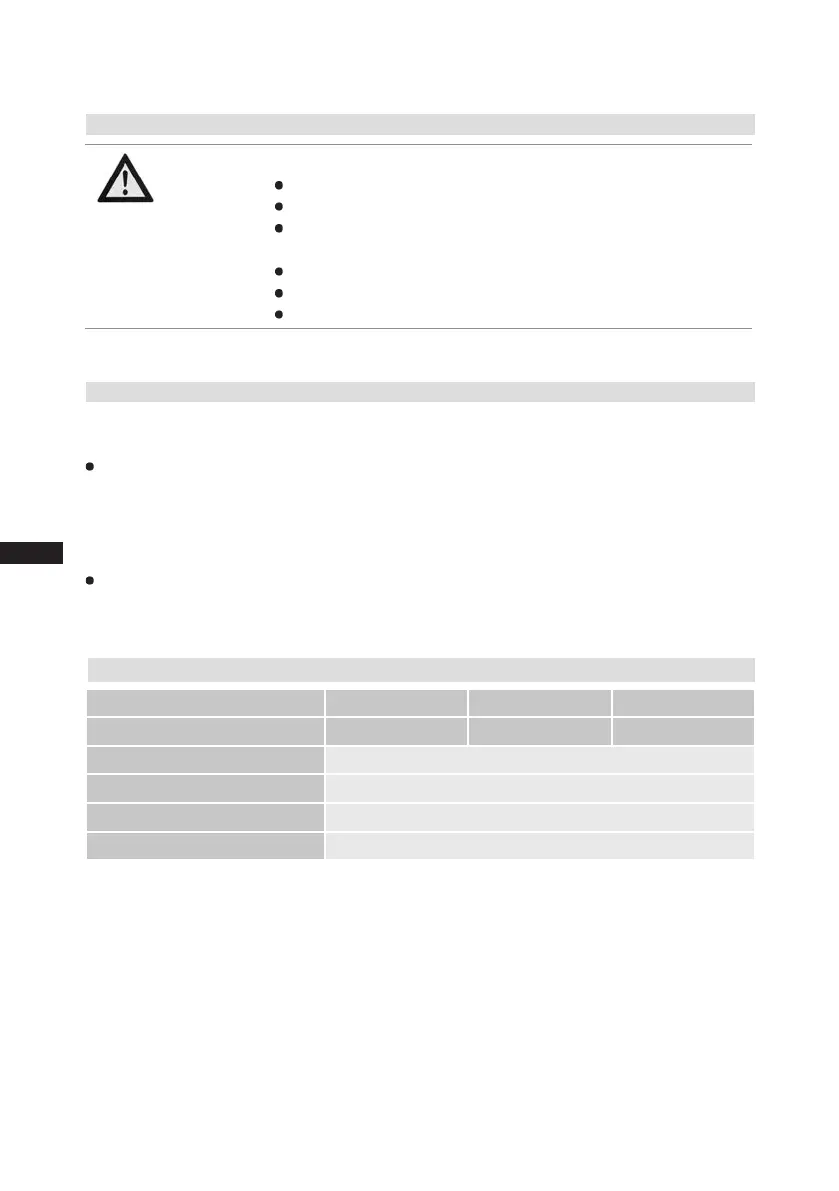

HG8 / ...

2470-4 (S) 2830-4 (S) 3220-4 (S)

Designation

Item No. Item No. Item No.

Set of gaskets kit 80235

Valve plate kit 80199

Oil pump kit 80290

Oil sump heater kit (220-240 V) 80237

Only use genuine GEA spare parts!

7.3 Recommended spare parts

7.1 Preparation

WARNING Before starting any work on the compressor:

Switch off the compressor and secure it to prevent a restart.

Relieve compressor of system pressure.

Preventairfrominltratingthesystem!

After maintenance has been performed:

Connect safety switch.

Evacuate compressor.

Release switch lock.

Loading...

Loading...