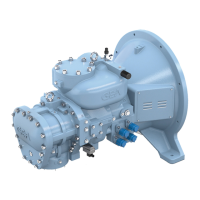

Why is the discharge pressure too high in my GEA Grasso 5 Air Compressor?

- MmarciamillerAug 16, 2025

If the discharge pressure of your GEA Air Compressor is too high, it might be due to several reasons: * The discharge stop valve may not be fully open. In this case, open it fully. * The discharge pressure gauge could be defective, requiring repair or replacement. * There might be non-condensables in the system. Purge the system using an automatic purger.