Do you have a question about the GEA HG7 Series and is the answer not in the manual?

Explains the meaning of various safety symbols and warning levels used in the document.

Specifies the required expertise and training for safe operation and maintenance.

Provides essential general safety guidelines for handling and operating the compressor.

Defines the proper applications and usage scope for the compressor.

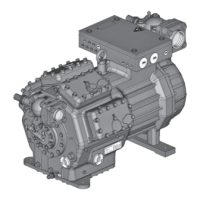

Provides a brief overview of the compressor's key features and design.

Explains the information presented on the compressor's name plate.

Details how to interpret the compressor model designation and its components.

Lists compatible refrigerants for use with the compressor.

Specifies the correct oil type and level for compressor lubrication.

Defines the operating boundaries and conditions for safe compressor performance.

Instructions on how to properly position and install the compressor.

Guidance on making secure and correct pipe connections to the compressor.

Details regarding pipes, cleaning, and vibration compensation.

Best practices for routing suction and pressure lines for optimal performance.

Procedures for opening and closing the compressor's service shut-off valves.

Explains the function and operation of the compressor's lockable service connections.

Guidance on selecting appropriate contactors and motor protection devices.

Electrical schematic for part winding motor starting configurations.

Details on wiring for standard motors in direct or part winding starts.

Wiring instructions for special motors in direct or star-delta starting configurations.

Electrical schematic for star-delta motor starting configurations.

Overview of the electronic trigger unit and its operational functions.

Instructions for correctly wiring the electronic trigger unit MP 10.

Procedure for testing the functionality of the MP 10 trigger unit.

Information on the oil sump heater accessory and its electrical connection.

Essential checks and preparations before compressor start-up.

Procedure for testing the system's pressure resistance.

Method for performing a leak test on the refrigeration system.

Steps for evacuating the system to remove air and moisture.

Instructions for correctly charging the system with refrigerant.

Detailed steps for the initial start-up of the compressor.

Guidance on preventing liquid slugging to protect the compressor.

Instructions on how to connect an oil level regulation system.

Safety precautions and preparation steps before performing maintenance.

General tasks for regular servicing and inspection of the compressor.

List of recommended spare parts and their corresponding item numbers.

Information on available accessories for the compressor.

Recommended oils and alternatives for compressor lubrication.

Procedures for safely removing the compressor from service.

| Brand | GEA |

|---|---|

| Model | HG7 Series |

| Category | Air Compressor |

| Language | English |

Loading...

Loading...