47

09665-08.2018-Gb

8

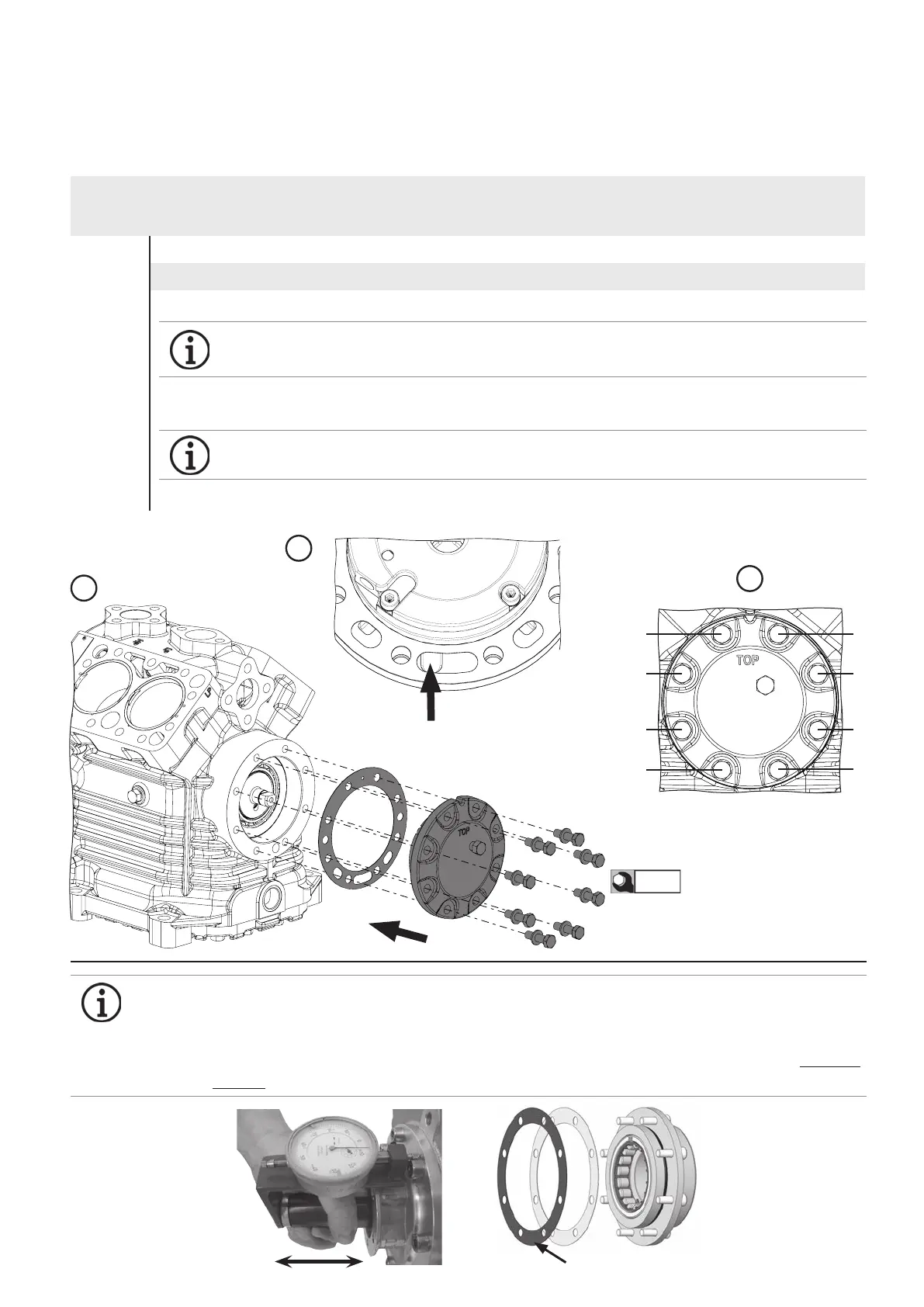

Install of the oil pump

Position in

parts list

Parts list position: 2020

Tools: Spanner SW 13

Working course

40, 41

460, 470

- The sealing surfaces have to be clean. Slightly oil seals

- Install the oil pump with gasket into the body with the inscription „TOP“ facing upwards!

- Screw oil pump tightly. Tighten the screws (M8x30) crosswise

12 I Assembly of compressor

34 Nm

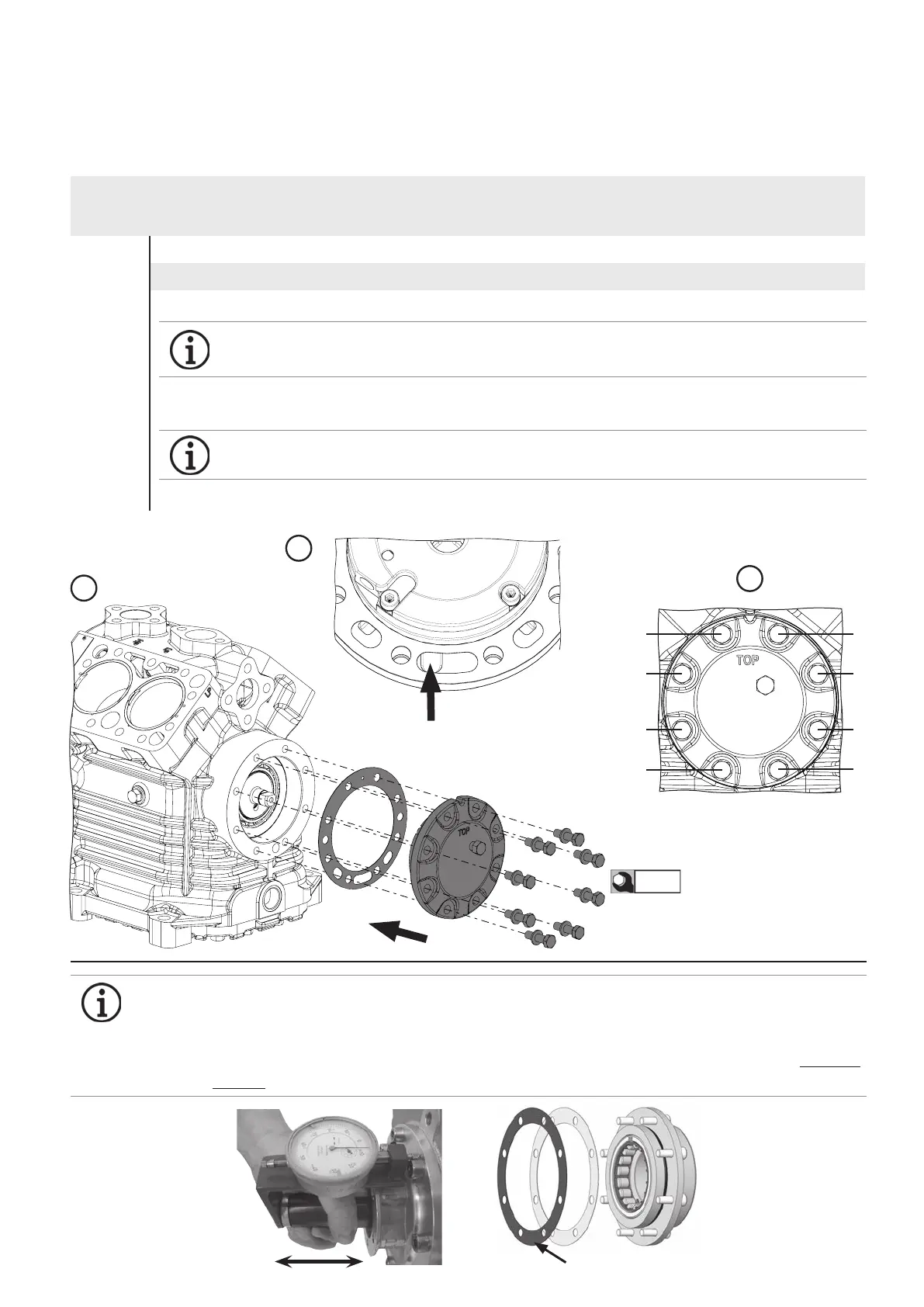

INFO Adjust axial clearance!

The axial clearance of the crankshaft must be at least 0.15 mm. When parts of the driving unit of the

compressor have been repaired or replaced, an accurate measurement of the axial clearance is neces-

sary. The measurement has to be at the disassembly shaft seal cover. If the axial clearance is less than

0.15 mm, the bearing ange must be disassembled and a second seal must inserted.

second seal

INFO Pay attention to the position of the holes in the gasket!

1

2

3

INFO Observe the tightening torques!

Pay attention to the tightening sequence of the screws!

1

4

6

8

2

3

5

7

Loading...

Loading...