20

Jointing methods

Geberit Drainage Systems

4.2 Electrofusion coupling

Available from Ø 40 to 315mm.

Connection properties

a Simple, reliable joint.

b Rigid, non-removable.

c Tension-resistant.

Application

On-site welding, slip coupling for adding fittings or

repairing sections.

The heat required to make the joint comes from flowing

a constant electrical current through the embedded

heater wires within the fitting. The pressure required

to make the joint is obtained from the shrinking of the

fitting under welding conditions. The shrinking does not

alter the internal bore of the joint because the ends and

the centre of the fitting are deliberately kept cold during

the welding process.

The joint obtained is simple, quick and strong once made.

The heater wires remain encased in the HDPE so there is

no chance of corrosion. The use of Geberit approved

equipment and fittings is essential to ensure a good weld

is made.

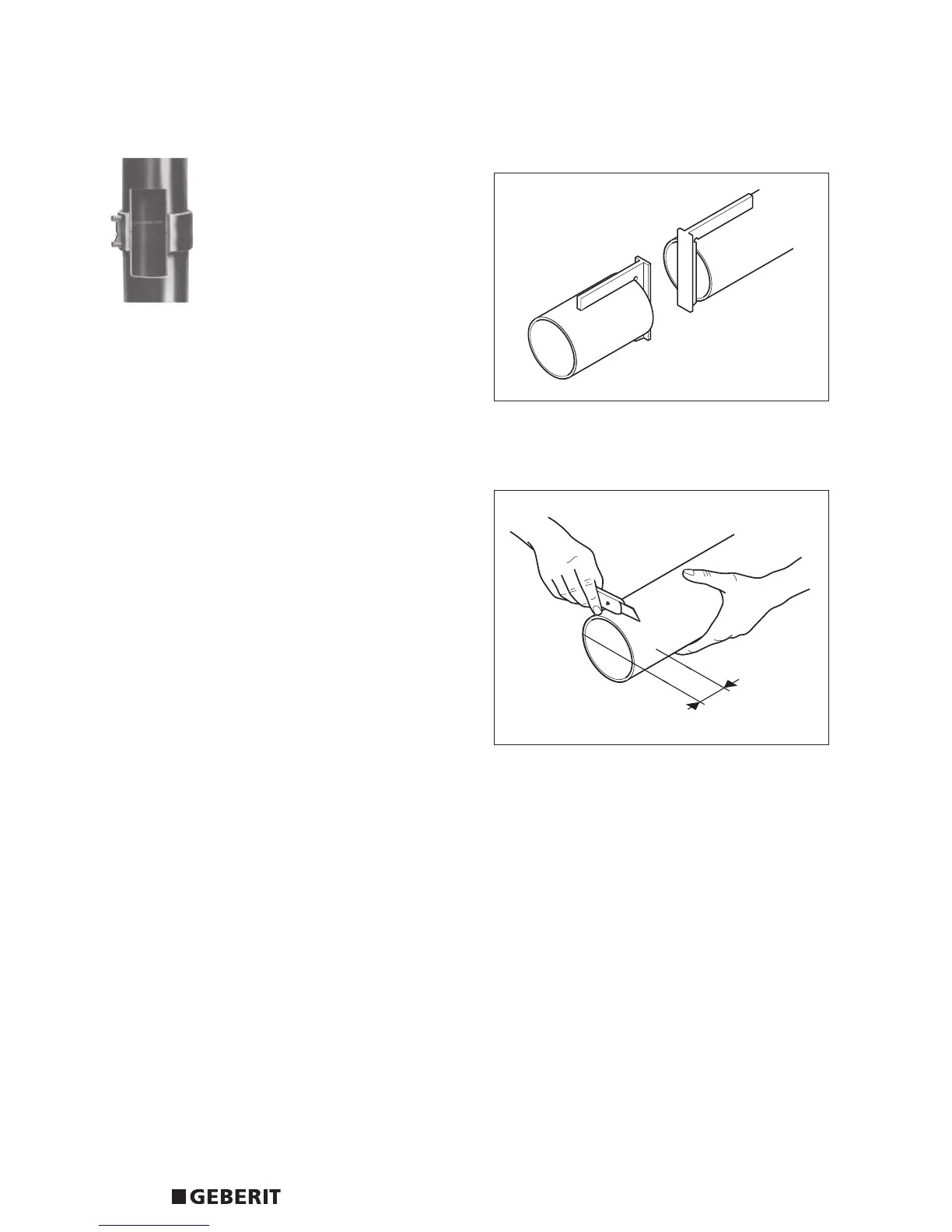

Preparation for electrofusion

Cut the pipe square.

Remove burr. Welding ends must remain dry during the

whole welding process. Mark 30mm insertion depth of the

electrofusion coupling on the pipe with a grease pencil.

Dry, clean and scrape welding ends. Scraping or abrading

of the pipe surface in the area to be fused is necessary

to remove oxide layer and ensure an effective weld.

Loading...

Loading...