62

Geberit Drainage Systems

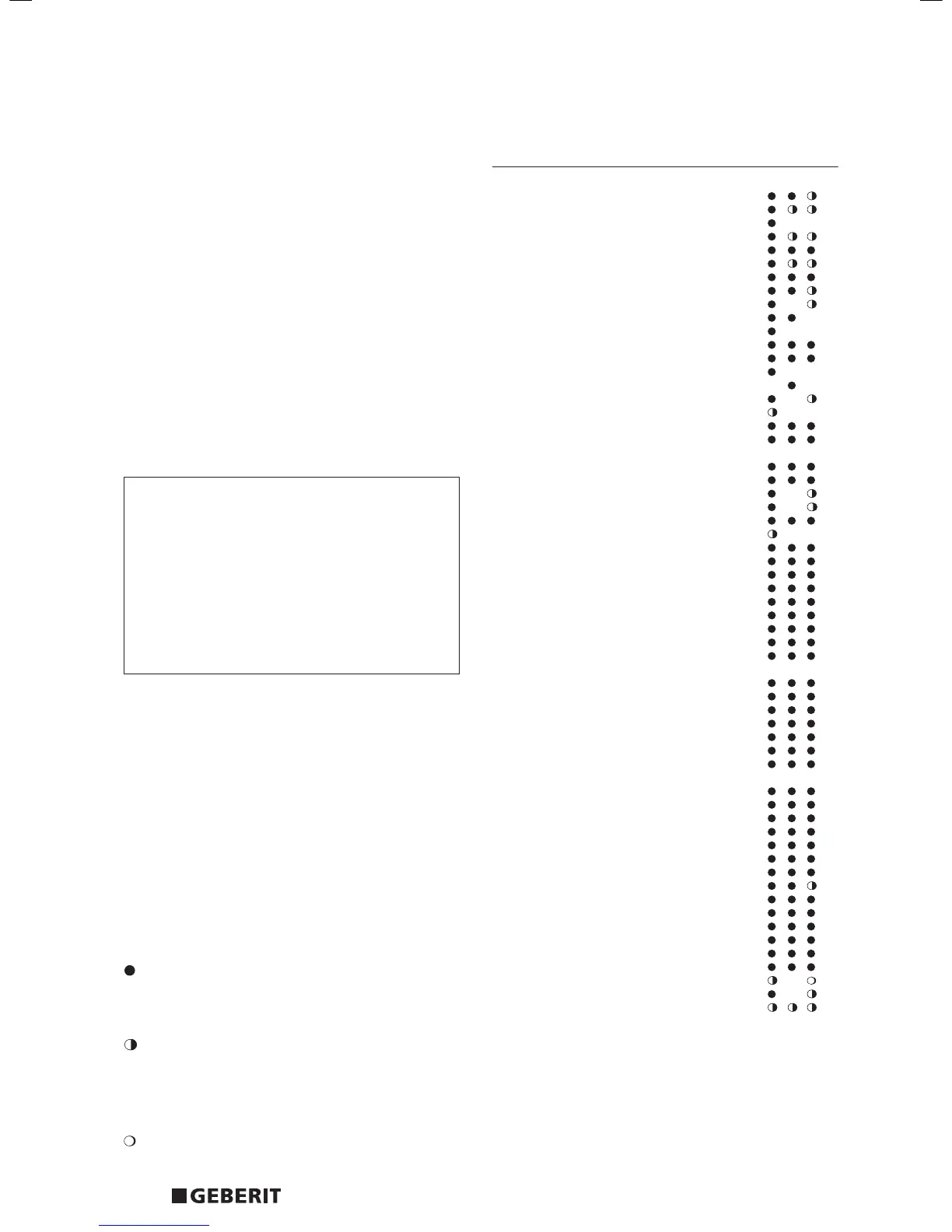

The following symbols and abbreviations are used to

indicate the composition of the flow substances:

% Percentages refer to mass proportions in %.

VL Aqueous solution, mass proportion <= 10%.

L Aqueous solution, mass proportion > 10%.

GL Aqueous solution saturated at 20°C.

TR Chemical is at least technically pure.

H Normal commercial composition.

S Traces < 0.1%.

G Usual mass proportion of any saturated

solution or dilution.

Data is based on immersion tests without mechanical load

and reflects current levels of knowledge. No claims under

guarantee may be made on the basis of this information.

Chemical resistance

Appendix: Chemical Resistance

The following data is required for a declaration

of chemical resistance:

• Corrosion medium, composition (chemical

description), DIN safety data sheet.

• Temperature.

• Proportion (concentration).

• Information on reaction time, frequency, flow quantity.

• Other flow media.

Acetic aldehyde 40

Acetic aldehyde TR

Acetic aldehyde+acetic acid 90:10

Acetanhydride (acetic anhydride) TR

Acetamide TR

Acetanhydride TR

Acetic acid 70

Acetic acid 100

Acetic acid butyl ester

Acetic ether (ethylacetate) 100

Aceto-acetic acid

Acetone VL

Acetone TR

Acetophenone TR

Acetylene

Acronal dispersions H

Acronal solutions H

Acrylonitrile TR

Acrylic acid-emulsions

Acrylic acid ethylester 100

Activine (chloramine 1%)

Adipinic acid GL

Adipinis acid ester

Allyl acetate

Allyl alcohol 96

Allyl chloride

Alum (potassium aluminium sulphate) any

Aluminium chloride VL

Aluminium chloride GL

Aluminium chloride, solid

Aluminium fluoride GL

Aluminium hydroxide

Aluminium metaphosphate

Aluminium sulphate any

Aluminium sulphate, solid

Amidosulphates

(amido-sulphonic acid salts) any

Amido-sulphonicacid any

Amino acids

Ammonia, gaseous 100

Ammonia, liquid 100

Ammonia solution (ammonium hydroxide) any

Ammonium acetate any

Ammonium carbonate

and bicarbonate of ammonium GL

Ammonium carbonate any

Ammonium chloride (sal-ammoniac) any

Ammonium dihydrogen phosphate GL

Ammonium fluoride L

Ammonium hydrosulphide any

Ammonium metaphosphate

Ammonium nitrate any

Ammonium phosphate any

Ammonium sulphate any

Amonium sulphide any

Ammonium thiocyanate

Amyl acetate TR

Amyl alcohol TR

Amyl chloride 100

Amyl phthalate

Anilin (phenylamine) GL

Geberit HDPE

thrFlow ough substance

Proport. Performance at

% 20˚C 40˚C 60˚C

Explanation

When the pipe wall material comes into contact with

substances flowing through the pipe, different processes

can take place, such as the absorption of liquid (swelling),

the extraction of soluble elements in the material

(shrinkage) or chemical reactions (hydrolysis, oxidation

etc), that can sometimes cause the properties of the pipe

or pipeline parts to change.

The performance of pipes and pipeline parts when in

contact with effluent substances can be classed as follows:

NB: Does not cover systems incorporating EPDM seal rings.

Resistant

The pipe wall material is generally regarded

as being suitable.

Limited resistance

The suitability of the pipe wall material must be

checked in each individual case and, if necessary,

further tests should be carried out.

Not resistant

The pipe wall material is general

ly regarded

as being unsuitable.

Loading...

Loading...