1S9STOEN_26-5-17_ADL300_STO_STO Pag. 8/30

4 Safety system description

Safe Torque Off safety function is integrated into the drive family ADL300, and is managed by

means of two enable signals “ENABLE” and “SAFETY ENABLE”.

4.1 Device functionality and architecture

The system herein examined are Power Drive Systems (PDs) also called Inverter. A PDS is power

device connected one side to the mains (three-phase system) and on other side to the motor

power lines. Motor and other devices which are related to the system functionalities (relays, cables

The PDS makes the motor move according to the settings operator has defined.

From the electrical point of view PDS takes power from mains to the motor lines.

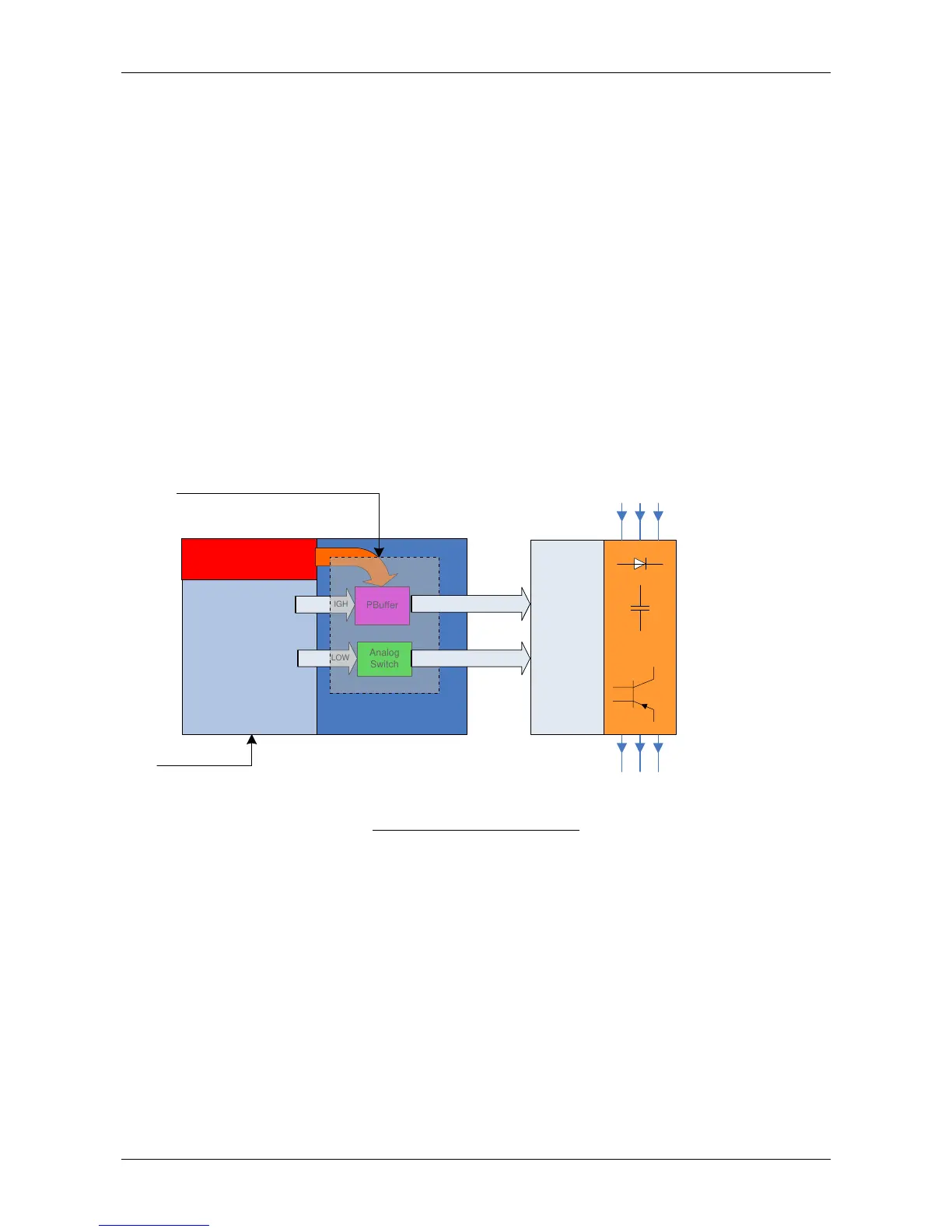

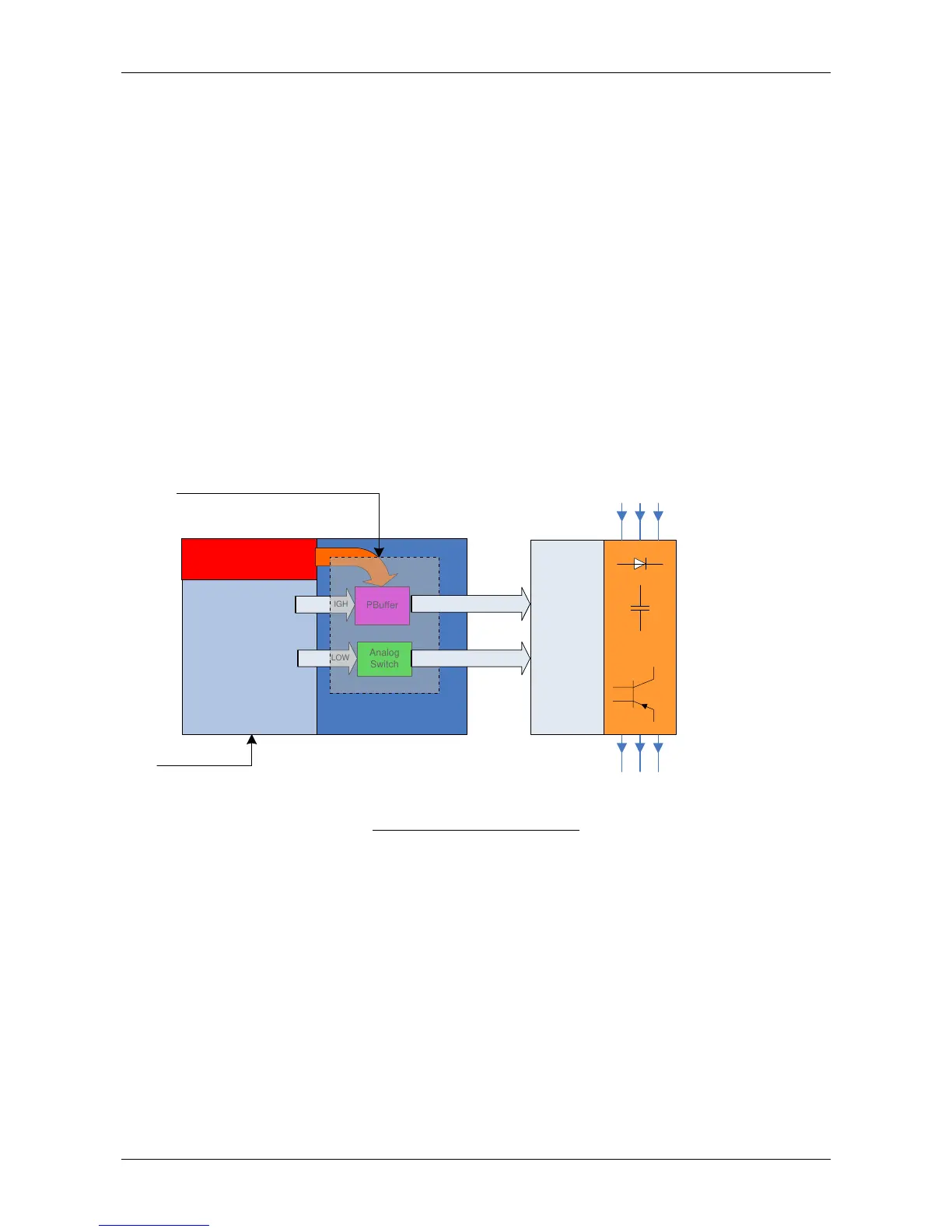

Inverter device family called ADL300 is subject of this document. From the safety and main

functionality points of view all devices of the family can be modeled as the same thing, herein

represented in Figure 1.

Figure 1 block diagram of PDs ADL300.

All ADL300 PDs are integrated PD devices featuring different power ratings, dimensions as well as

enclosures. Though from the functional and electrical points of view all devices are made up of the

same fundamental four parts:

1. Regulation board

2. Driver board

3. IGBT power module

4. Safety part

Follows a brief description of four parts:

Regulation board: exists as separate PCB, main purpose of this board is to generate

coordinated PWM pulses going to the IGBT gates. PWM pulses are controlled and

generated by the software according to the settings to provide given voltage, current,

motor speed, motor acceleration, etc options. PWM pulses can be cancelled out

directly onto the regulation board by means of a PWM inhibit signal which acts directly

Loading...

Loading...