116 918496/GP0313

Fuel System

Use only proper types and grades of diesel fuel

(See “Fluid Capacities/Lubricants” on

page 31). Diesel fuel is flammable. Keep the machine away from

open flames. Do not smoke when refueling or when working on the

engine. Stop the engine before fueling. Failure to follow instructions

can cause fire and result in injury or death.

Important: The fuel tank is filled at the factory with United States off-road grade

diesel fuel, which is dyed red for identification. It may take several fillings of the

fuel tank before the red dye is purged from the fuel system.

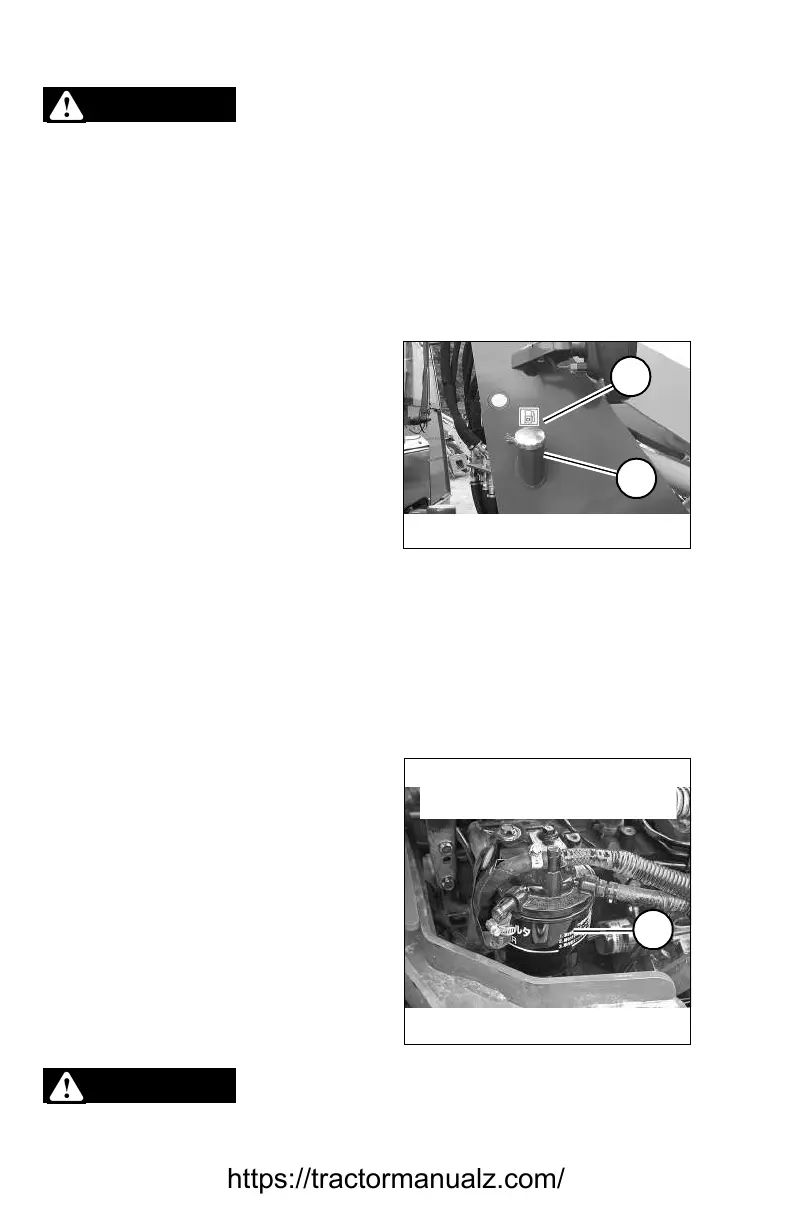

Adding Fuel

1. Perform the “Mandatory Safety Shut-

down Procedure” on page 10.

2. Remove fuel cap (M, Fig. 82).

3. Inspect the wire-mesh fuel strainer

located in the filler neck and remove

any accumulated residue that may be

present. Replace the strainer if dam-

aged.

4. Add fuel into fuel filler neck (N).

Important: The engine requires low

sulfur or ultra-low sulfur diesel fuel (below 500 PPM recommended). BioDiesel

mixtures of up to a 5% (B5) are acceptable. Ultra-Low Sulfur Diesel (ULSD) fuel

lubricity must have a maximum scar diameter of 0.45 mm, as measured by ASTM

D6079 or ISO 12156-1, or a minimum of 3100 grams, as measured by ASTM

D6078. Contact your fuel supplier for details.

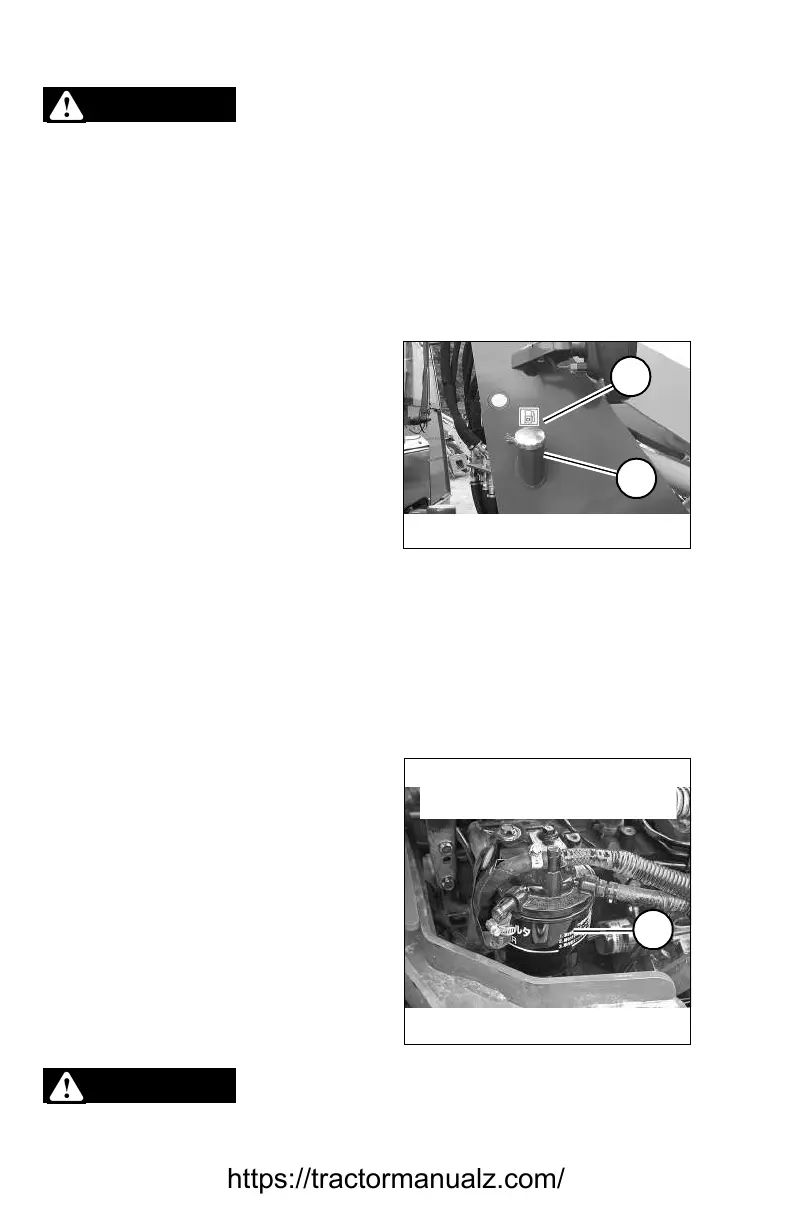

Changing Fuel Filter

The fuel filter (P, F i g . 8 3 ) is located in the

fuel line before the fuel pump. Access the

fuel filter by opening the engine cover and

tilting the platform. See “Tilting Up the

Platform” on page 107. Replace the fuel

filter at the interval specified in the

“Maintenance Schedule” on page 104

The fuel filter is located on the left side of

the loader.

1. Perform the “Mandatory Safety Shut-

down Procedure” on page 10.

2. Allow the machine to cool completely.

Fuel spilled on hot components can cause fire

and severe burns. Allow the machine to cool

completely before removing the fuel filter.

Figure 82 – Fuel Fill Neck

N

M

AL 500 Series shown

(other machines similar)

https://tractormanualz.com/

Loading...

Loading...