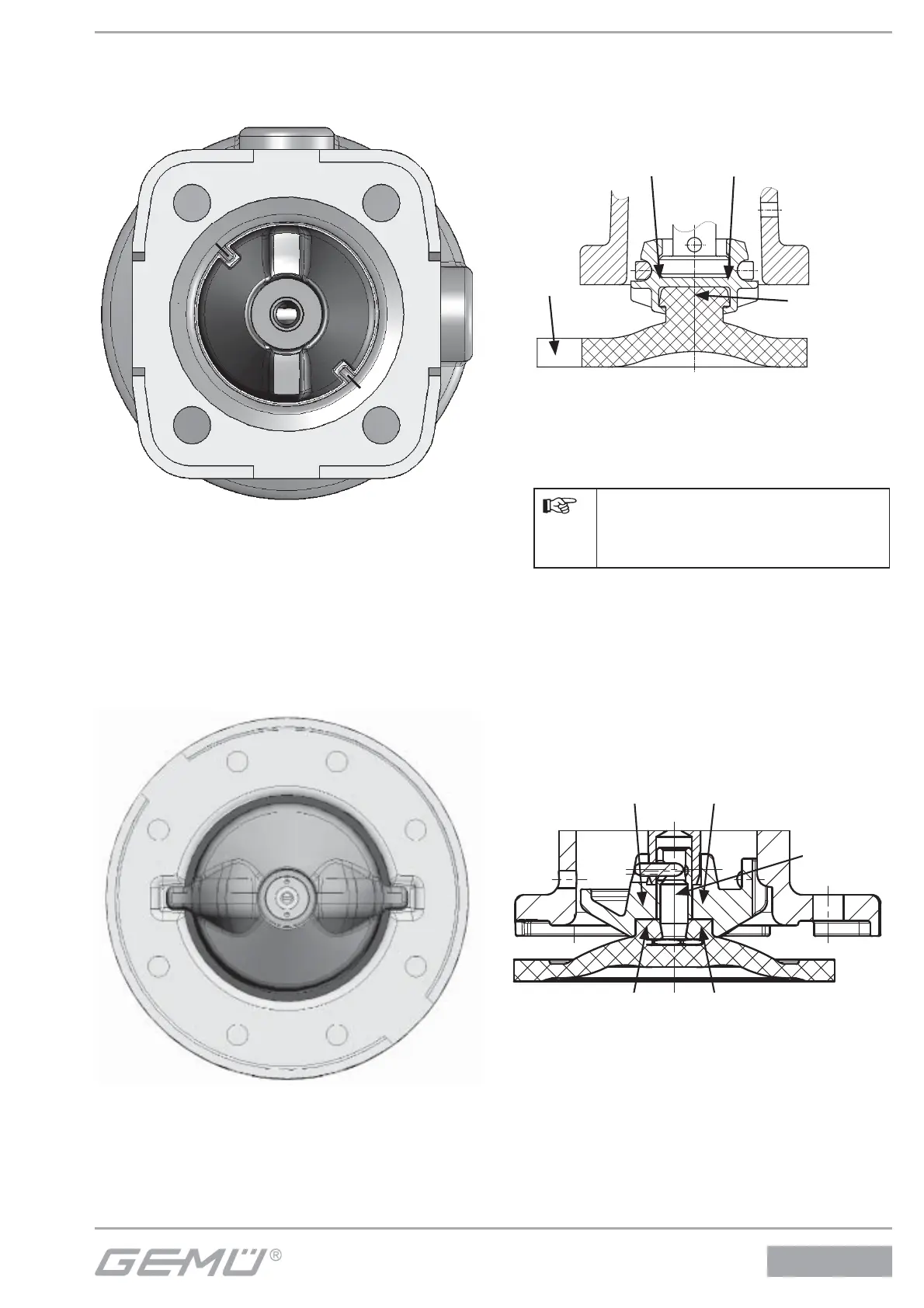

Diaphragm size 25 - 80:

Compressor and actuator flange seen from

below:

D

C

C

D

Place the compressor loosely on the

actuator spindle, fit the recesses D into the

guides C. The compressor must be able to

be moved freely between the guides!

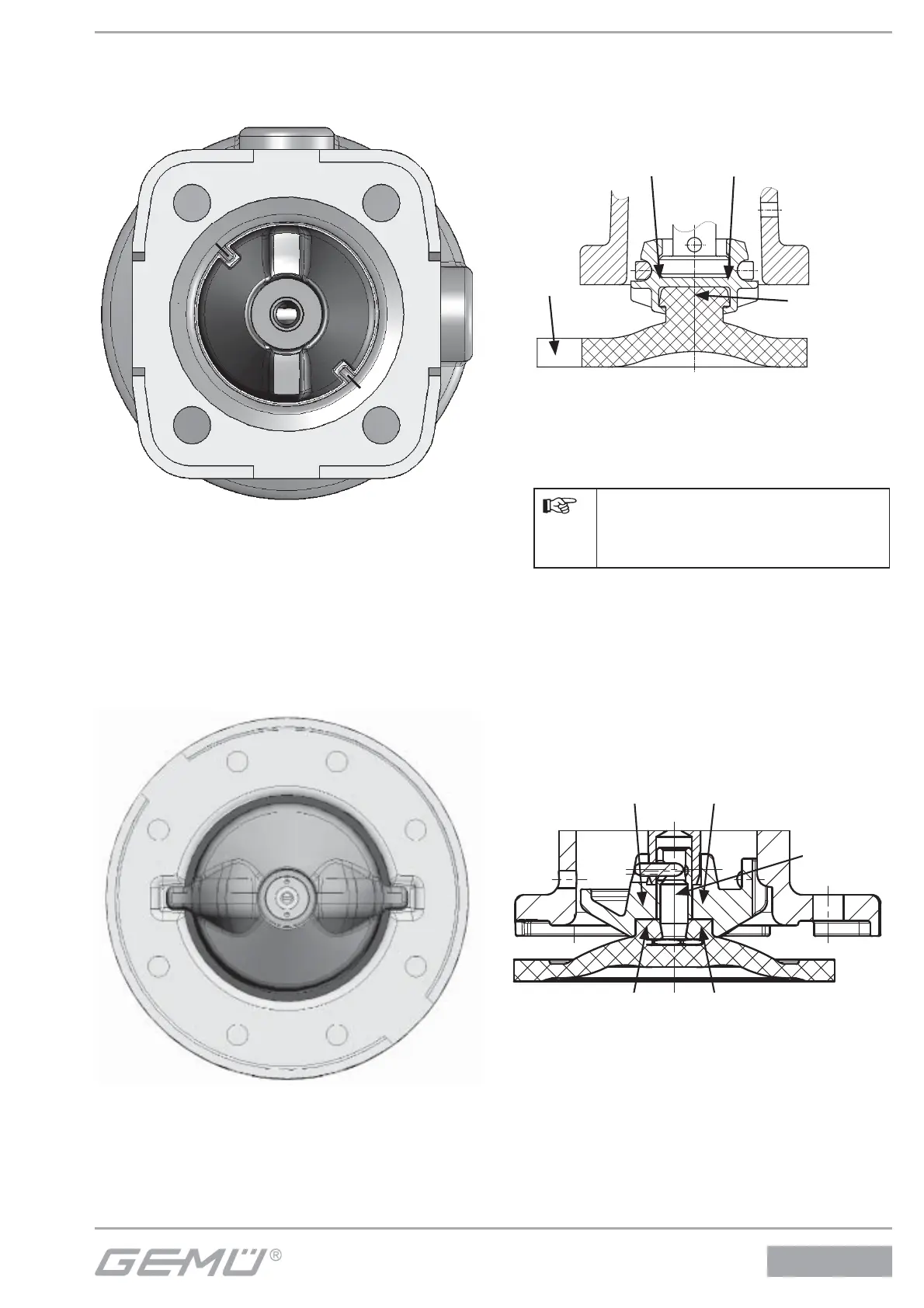

Diaphragm size 100:

Compressor and actuator flange seen from

below:

11.3.2 Mounting a

concave diaphragm

Diaphragm size 8

Push-fit diaphragm:

Ta b

Fastening

spigot

Recess of compressor

1. Move actuator A to the closed position.

2. Place the diaphragm 2 with the fastening

spigot in an inclined position at the

recess of the compressor.

Important:

Do not use greases or

lubricants!

3. Turn the diaphragm as manual force is

applied to push the spigot into the

compressor.

4. Align diaphragm tab with identifying

manufacturer and material in parallel to

compressor weir.

Diaphragm sizes 10 - 100

Threaded pin type diaphragm:

Diaphragm boss

Recess of compressor

Diaphragm

pin

1. Move actuator A to the closed position.

2. Diaphragm size 10: Ensure that the anti-

twist system is engaged.

Diaphragm sizes 25 - 80: Place the

compressor loosely on the actuator

spindle, fit the recesses into the

guides (see chapter 11.3.1 "General

information")

41 / 52

650

Loading...

Loading...