Section 4 AC Diagnostic Tests

Diagnostic Repair Manual 53

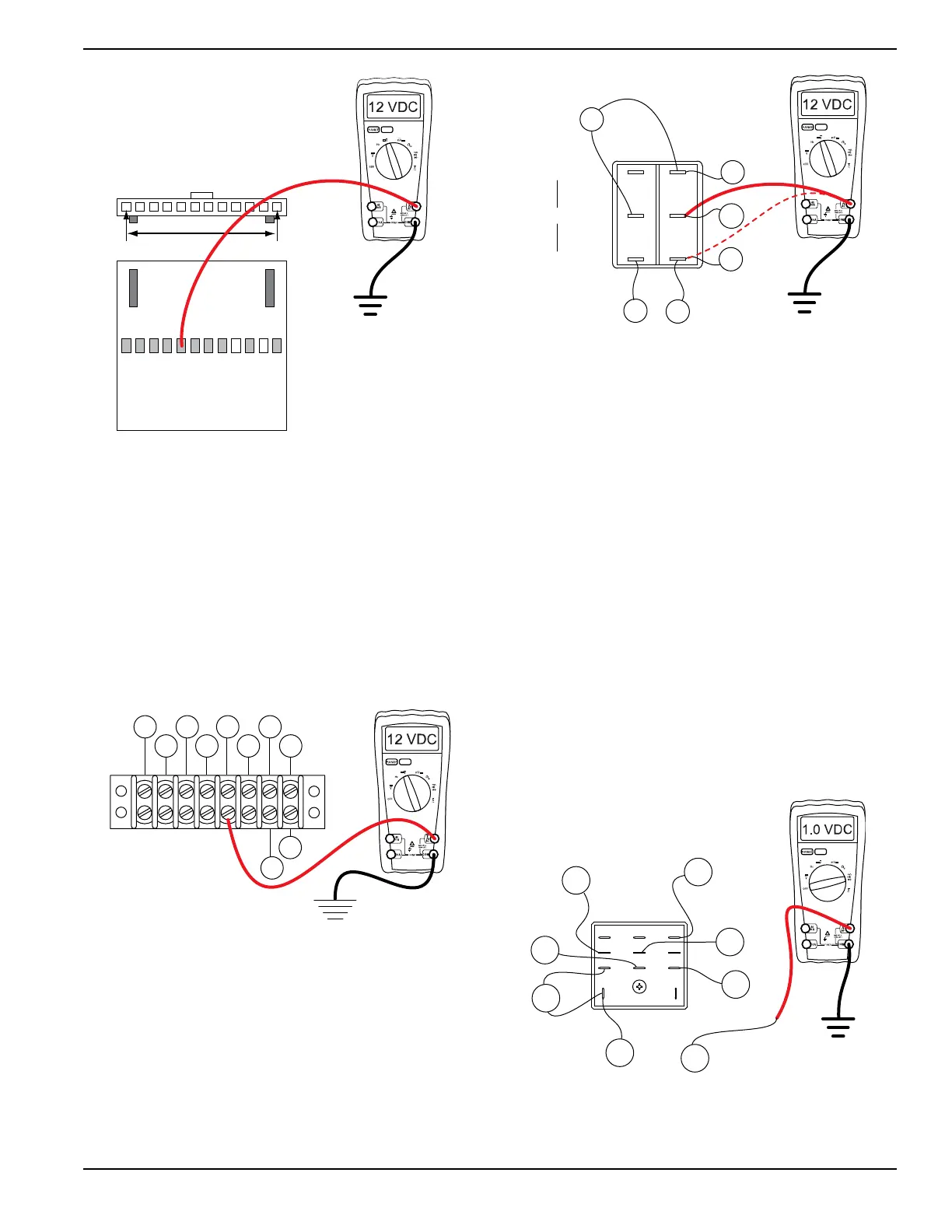

Figure 4-43. Test Wire 167, Steps 2-5

7. Connect the negative meter test lead to frame

ground.

8. Set the start-run-stop switch (SW1) to START. 12

VDC should be measured.

a. If 12 VDC is measured, replace wire 167

between TB1 and the J2 connector.

b. If 12 VDC is not measured continue testing.

9. Connect the positive test lead to wire 167

connected at the start-run-stop switch (SW1).

10. Connect the negative meter test lead to frame

ground.

Figure 4-44. Test Wire 167, Steps 6-8

11. Set the start-run-stop switch (SW1) to START. 12

VDC should be measured.

a. If 12 VDC is measured, repair or replace wire

167 between SW1 and the TB1.

b. If 12 VDC is not measured continue testing.

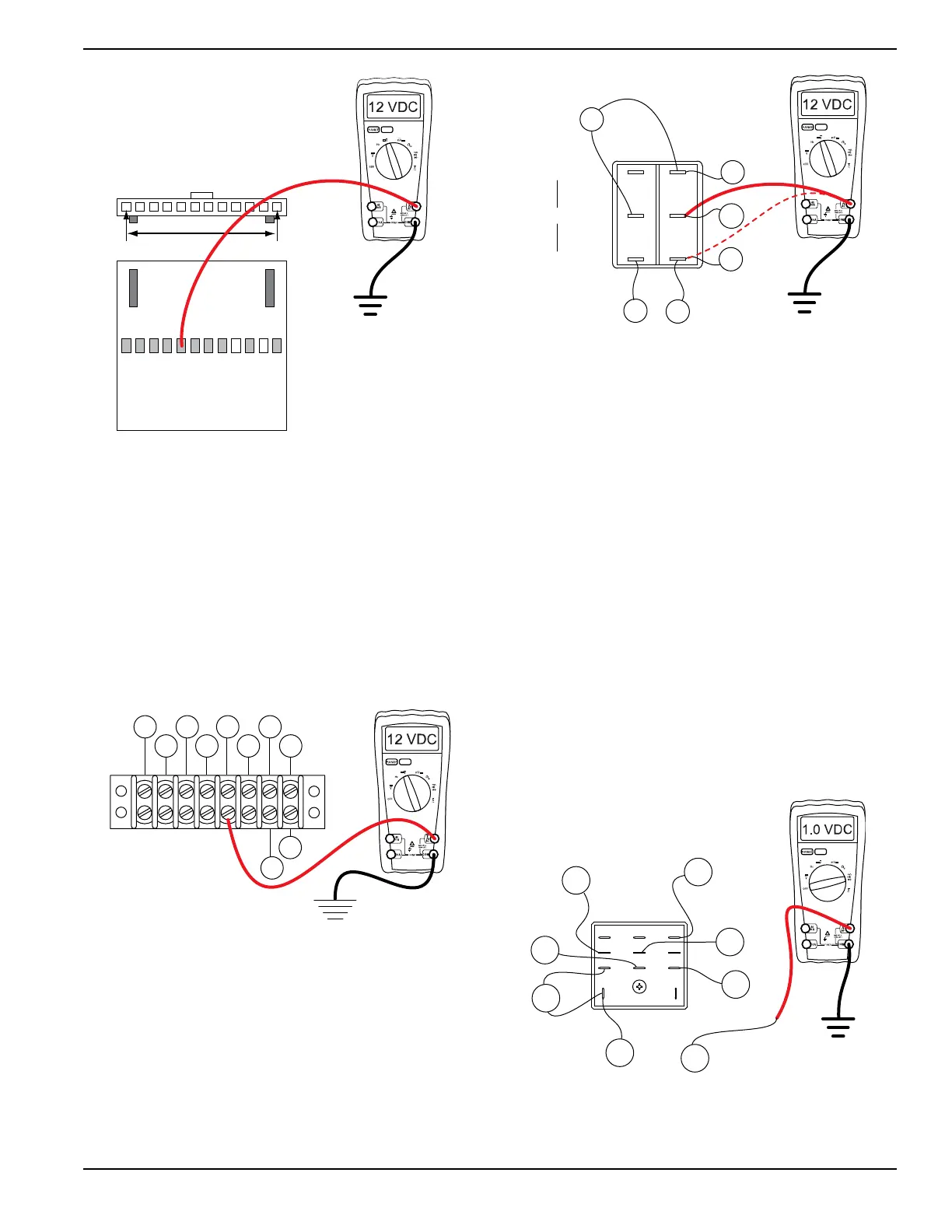

12. See Figure 4-45. Connect the positive meter test

to wire 15 at SW1.

Figure 4-45. Test Wire 167, Steps 9-13

13. Connect the negative meter test lead to frame

ground. 12 VDC should be measured.

a. If 12 VDC is measured, replace SW1.

b. If 12 VDC is not measured repair or replace

wire 15 between SW1 and the Starter

Contactor Relay (SCR).

Test 34 – Test Start Stop Relay Wiring

Procedure

1. Set DMM to the diode test range.

2. Disconnect wire 229 from the start stop relay

(SSR).

3. Connect the positive meter test lead to wire 229

removed in step 2.

4. Connect the negative meter test lead to frame

ground.

5. See Figure 4-46. Set the start-run-stop switch

(SW1) to START. The meter should read

approximately 1.0 VDC.

a. If the correct voltage is indicated, stop testing.

Figure 4-46. Testing Wire 229 to Ground

6. Set DMM to measure resistance.

J2 HARNESS CONNECTOR

J2-1 J2-12

TERMINAL

BLOCK

(TB1)

86 15B

167

BLK

0 229

83

BLK

TR2

TR1

167

STOP

0

15

15

17

4

5

6

1

2

3

RUN

START

STEP 4

STEP 5

0

SSR

15B

1413

9 10 12

5

1 2

6

4

8

229

0

18

14

15

15

15

Loading...

Loading...