12-2

SECTION 12: PISTON, RINGS & CONNECTING ROD INSPECTION & ASSEMBLY

Figure 12-4. Checking Ring End Gap

Figure 12-5. Check Piston Pin Bore

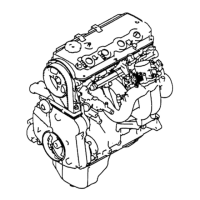

CHECKING PISTON PIN AND CONNECTING ROD

1. Check piston pin, Figure 12-6.

a. Replace if less than 19.97mm (.7862") or if it is .01mm

(.0005") out of round.

2. Check connecting rod bearings.

Note: If crankpin bearing is scored or worn the connect-

ing rod must be replaced.

Figure 12-6. Check Piston Pin

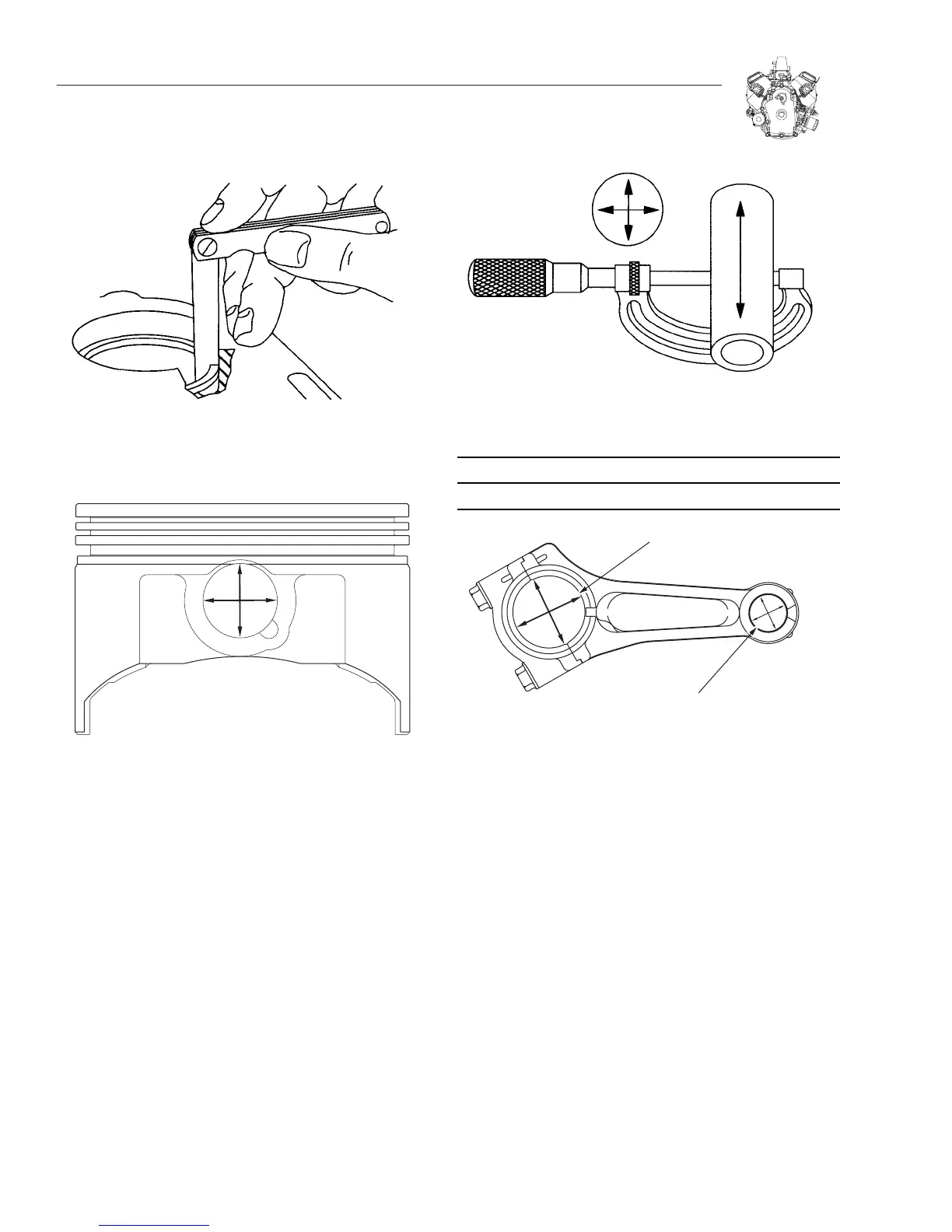

CONNECTING ROD REJECT SIZE

Crankpin Bearing Piston Pin Bearing

39.09mm (1.539") 20.05mm (.7894")

Figure 12-7. Check Rod Bearings

ASSEMBLE PISTON AND CONNECTING ROD

Lubricate parts with engine oil and assemble #1 piston and

connecting rod, Figure 12-8.

1.Notch or casting mark on piston must be on flywheel side.

2.Number "1" on connecting rod must face PTO side (oppo-

site notch or casting mark on piston).

a. Install piston pin locks with needle nose pliers.

Lubricate parts with engine oil and assemble #2 piston and

connecting rod, Figure 12-9.

1.Notch or casting mark on piston must be on flywheel side.

2.Number "2" on connecting rod must face PTO side (oppo-

site notch or casting mark on piston).

a. Install piston pin locks with needle nose pliers.

Loading...

Loading...