14

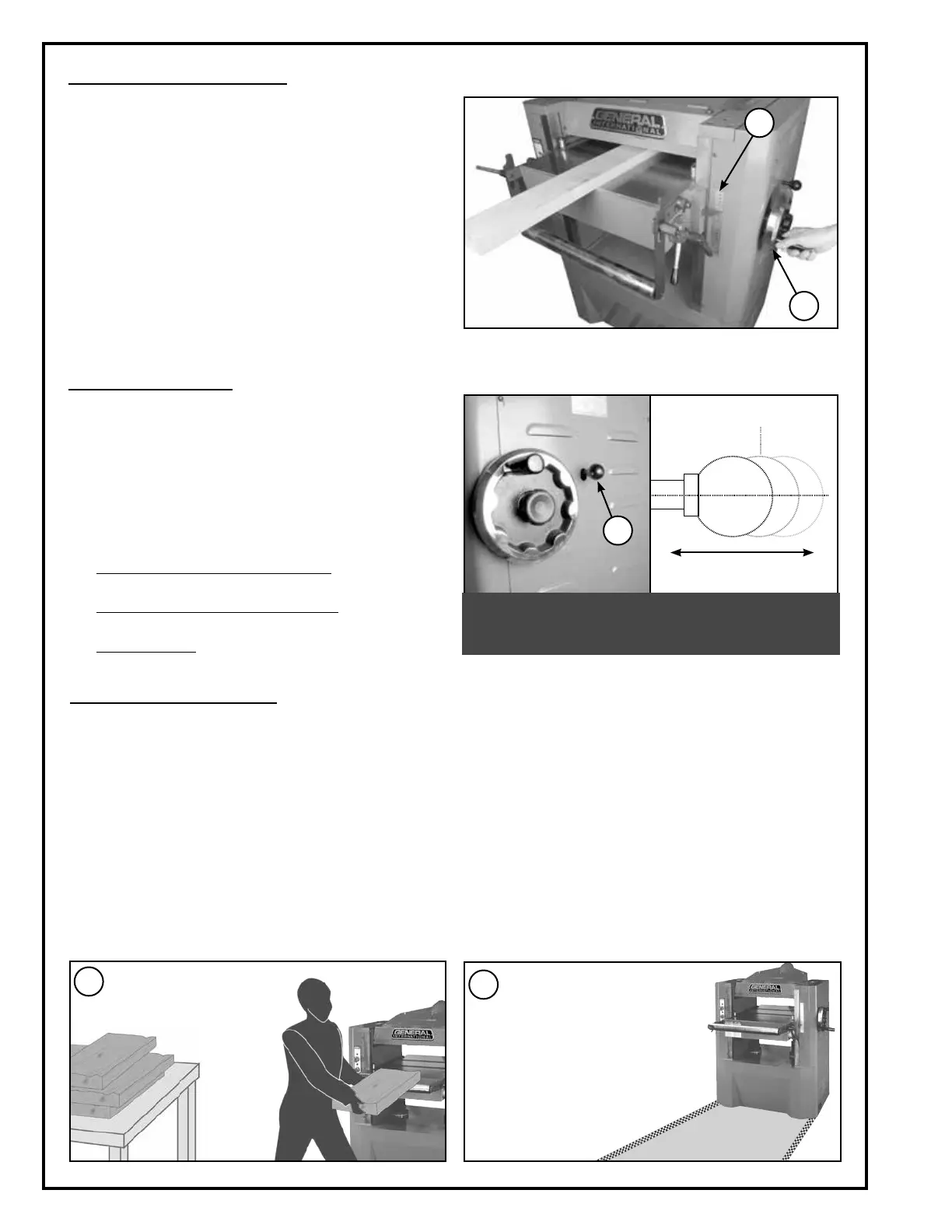

CHECKLIST BEFORE STARTING

• Make sure the board has been inspected and is suitable for planing as explained in section “Selecting boards

suitable for planing”.

• Make sure you and any assistants are wearing safe appropriate workshop attire. Roll up long sleeves, secure

long hair and remove any jewelry: watches, rings, bracelets or anything that could become caught in the mov-

ing parts, potentially causing serious injury.

• Make sure to have on safety glasses as well as hearing and respiratory protection at all times when using the

planer.

• To reduce the risk of damage to the planer or the workpiece, as well as a potential for personal injury, after initial

set-up as well as before each use, make sure that everything is securely installed and that all fasteners and mov-

ing parts on this machine are locked in place before starting the machine.

• If multiple boards are to be planed, collect all workpieces together and set them nearby on a table or bench

within easy reach D. To limit the potential for injury in the event of a kickback, avoid having to step or reach in

front of the machine to pick up the next workpiece E.

D

E

AVOID HAVING TO STEP

OR REACH IN FRONT OF

THE MACHINE!

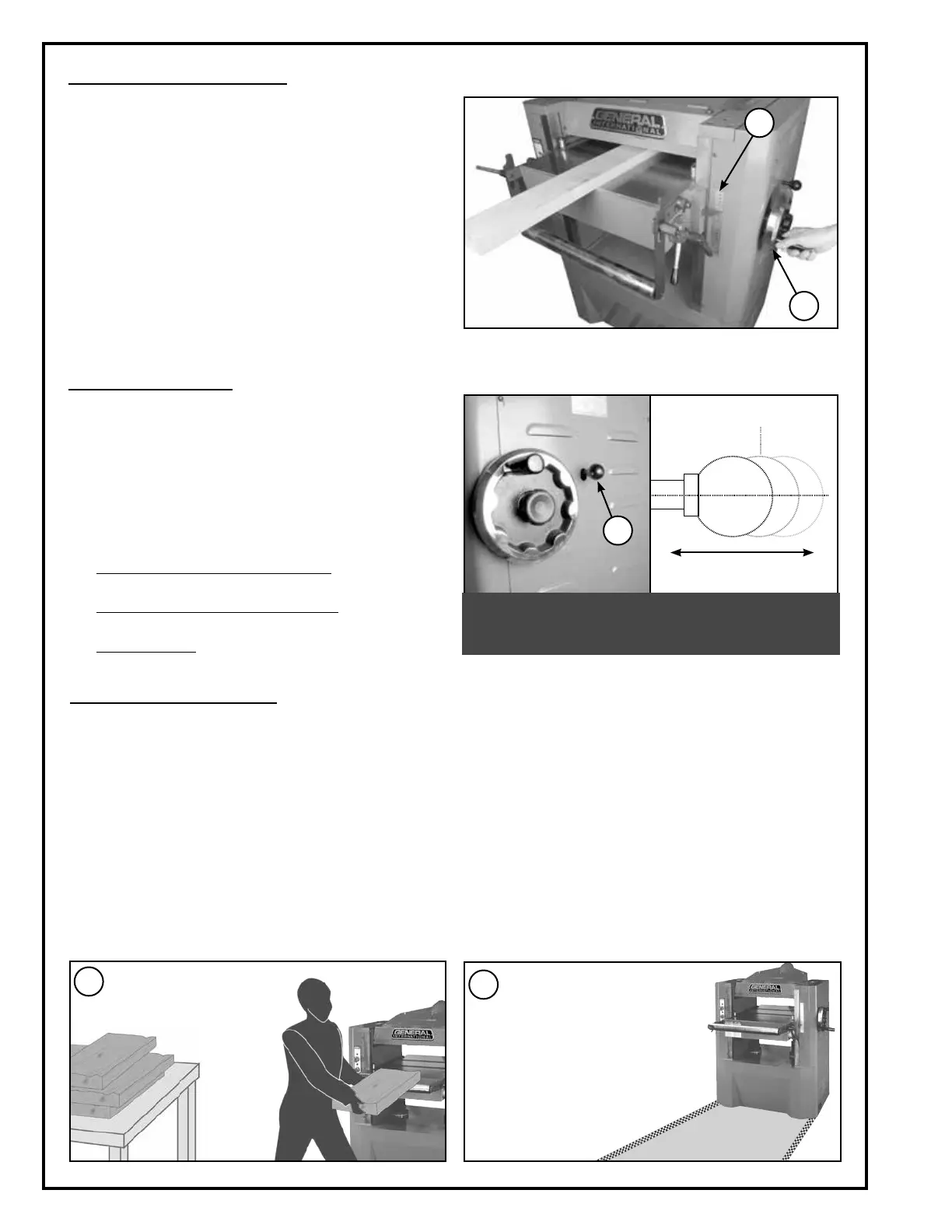

ADJUSTING THE DEPTH OF CUT

The depth of cut is adjustable by using the handwheel

A. Remind that the maximum depth of cut on full

width planing is 1/8” and lowering the head assem-

bly. It is recommended that for both hard and soft wood:

removing less material per pass and taking multiple

passes is always preferred to more aggressive planing.

1. turn off the machine.

2. Position the board under the infeed roller and ad-

just the position of the table work with the hand-

wheel A so that the infeed roller is in contact with

the board.

3. Remove the board and adjust the cutting depth us-

ing the scale B by turning the handwheel A clock-

wise.

B

A

ADJUSTING FEED SPEED

Two rollers turn and feed the stock. The feed motor

speed ranges from 22 to 28 fpm (feet per minute). The

feed speed adjustment knob is located on the right

hand side of the machine.

Select appropriate feed speed for the stock being

plane: high speed for softwood and slow for hardwood.

Experiment with feed speeds based on the workpiece

material and its width as well as the depth of cut, to find

which setting work best for your needs.

- To increase the feed rate at 28 fpm, pull the knob C

out.

- To decrease the feed rate at 22 fpm, push the knob

C back.

- For zero speed, set the knob C in neutral position.

22 fpm

0

28 fpm

NOTE: TO AVOID DAMAGE TO THE GEARBOX, SPEED CHANG-

ES SHOULD ONLY BE MADE WHILE THE MACHINE IS RUNNING.

C

Loading...

Loading...