MAKE SURE THE MACHINE HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORM-

ING ANY MAINTENANCE OR ADJUSTMENTS.

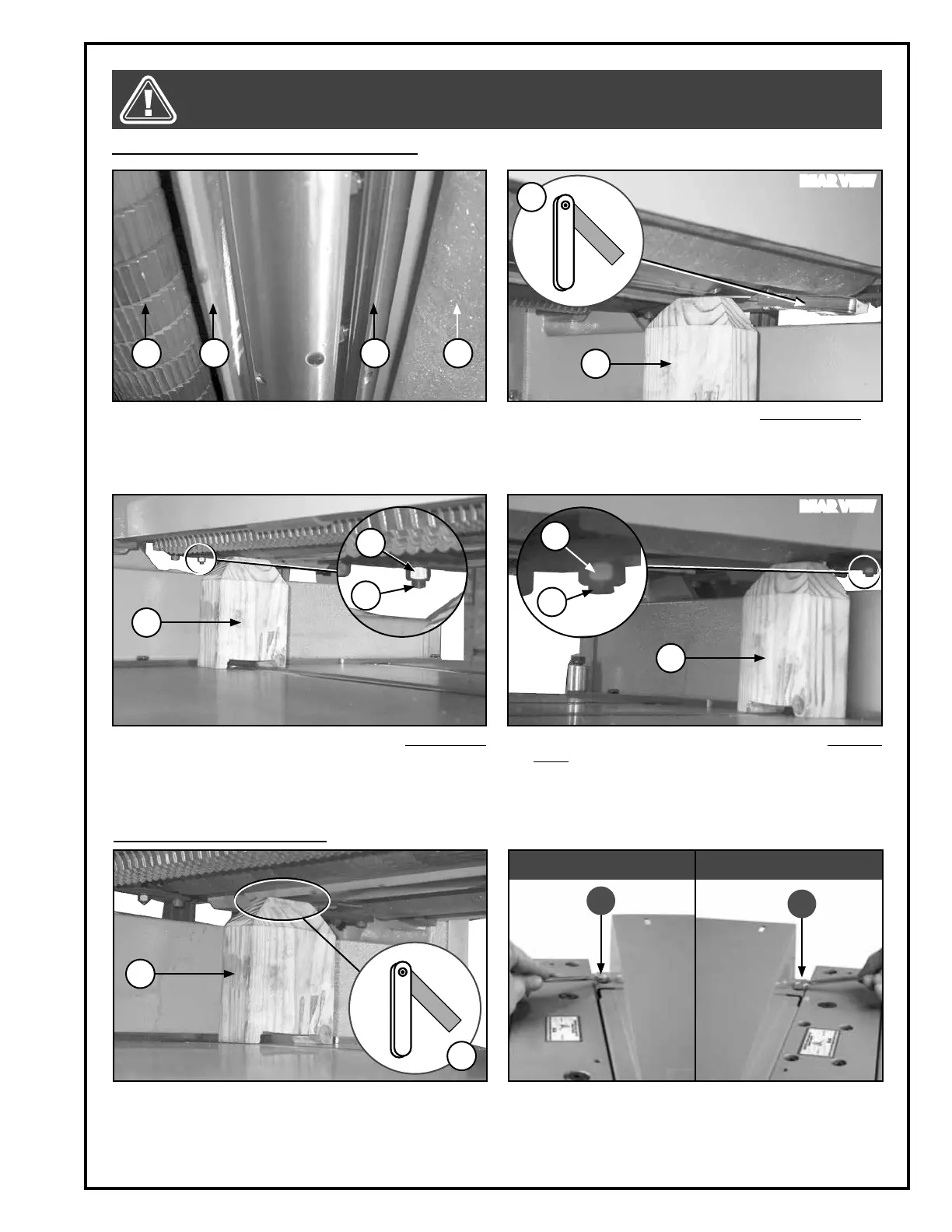

ADJUSTING THE INFEED & OUTFEED ROLLERS

1. Begin by take note of all the components in order

to make required adjustments: A infeed roller; B

chipbreaker; C cutter head with knife/insert; D out-

feedroller.

2. Place the gauge block E under the knife/insert C,

adjust the table height until you can only slide a

0.02” feeler gauge F between the block and the

cutter. Once finished, do not move the height of the

table.

A B

C

D

E

F

ADJUSTING THE CHIPBREAKER

3. Place the block E under the end of the infeed roller

A as shown. Loosen the nut G, turn the screw H until

the roller touches the top of the block, and then re-

tighten the nut G. Repeat for the other end.

4. Place the block E under the end of the outfeed

roller D. Loosen the nut I, turn the screw J until the

roller touches the top of the block, and then re-

tighten the nut I. Repeat for the other end.

E

E

G

H

I

J

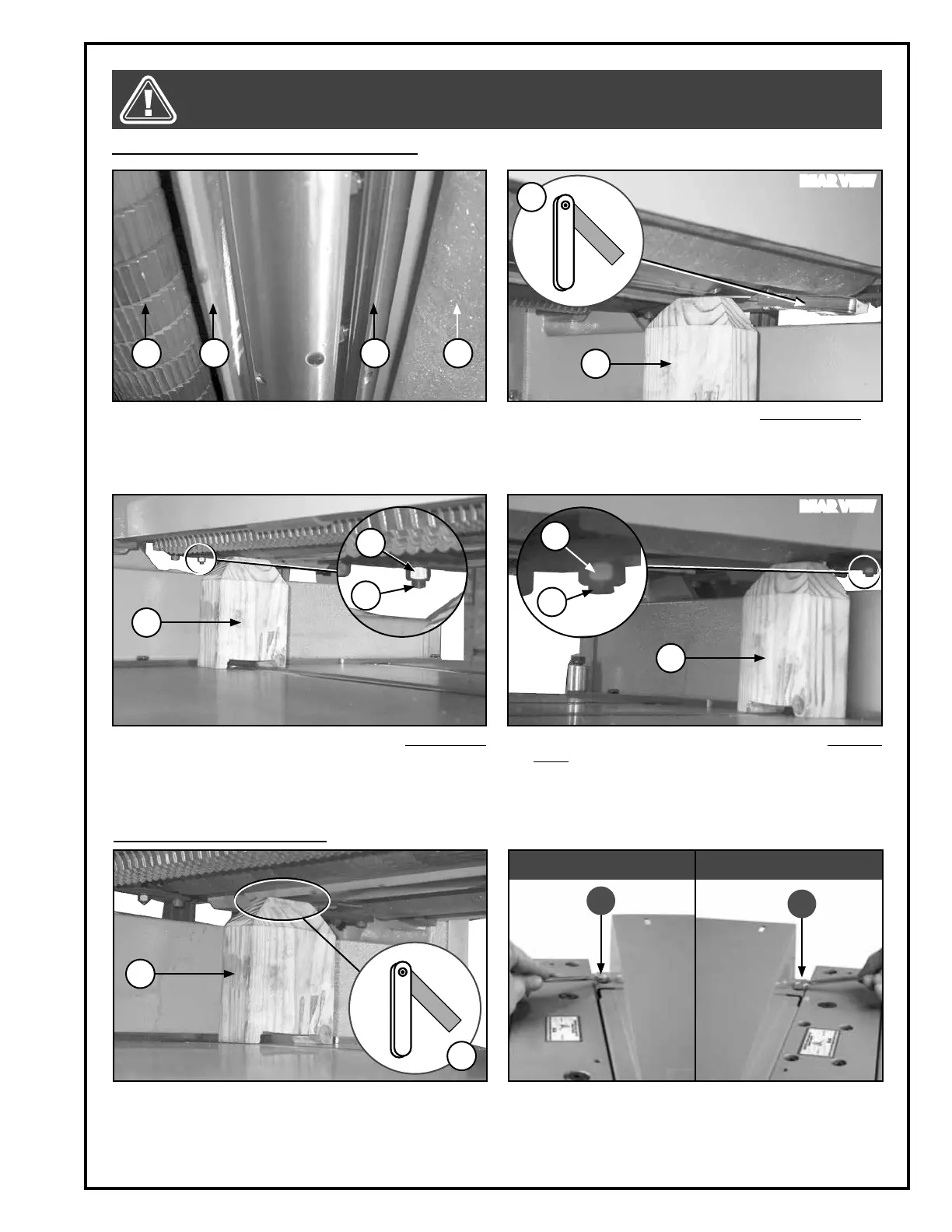

1. Place the block E under a knive/insertion and ad-

just the table height until you can slide only a 0,004”

feeler gauge K between the block E and the knive/

insertion. Then place the block under the chip-

breaker B.

E

K

2. Remove the dust chute, remove the two bolts L with

a 10 mm wrench, and then lift the chip deflector

cover in order to access the cutter head.

L

L

LEFT SIDE RIGHT SIDE

REAR VIEW

REAR VIEW

17

Loading...

Loading...