BRAIN 15

ENGLISH

Guide for the installer

Page 15

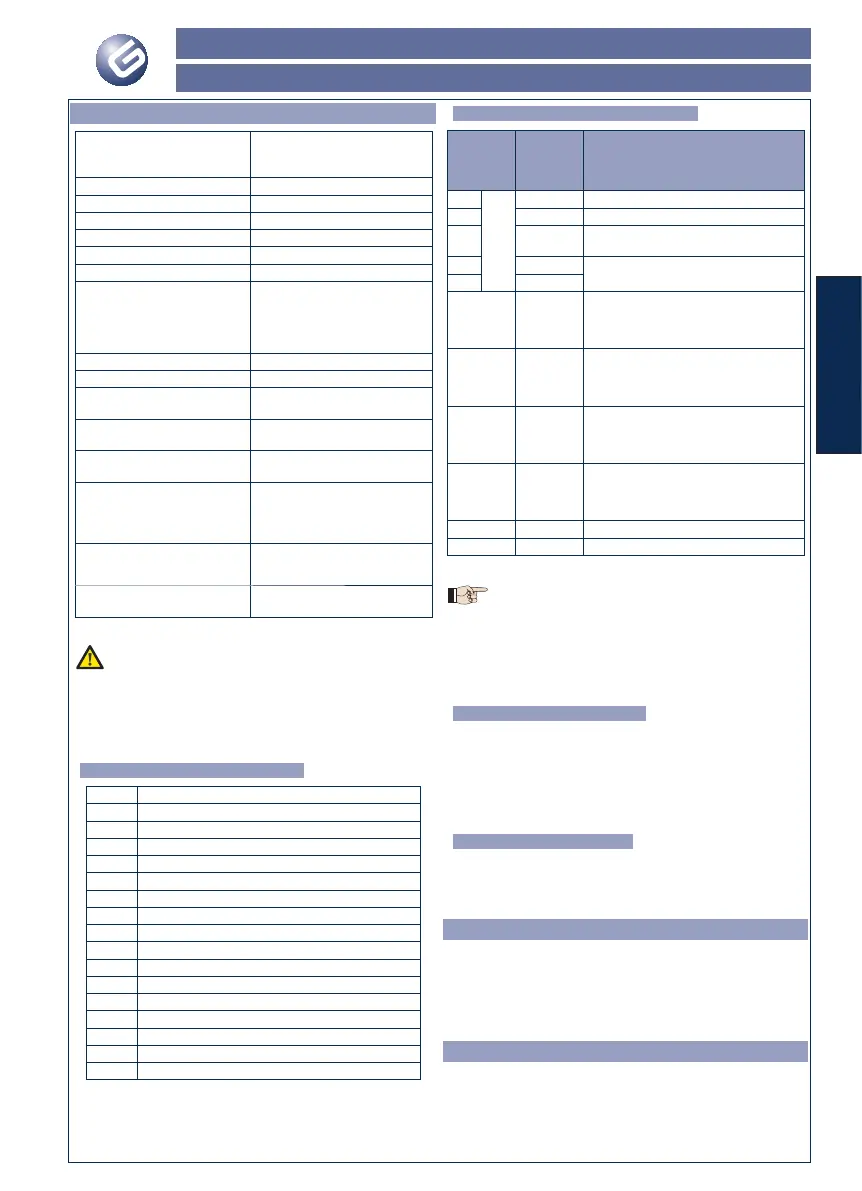

3. TECHNICAL SPECIFICATIONS

Power supply voltage

230Vac (+6% -10%) - 50Hz

or

115Vac (+6% -10%) - 60Hz

Supply voltage of control unit

24 Vac nominal

Absorbed power 4W

Motor max. load 150W x 2

Accessories max. current (+24V) 250 mA

BUS Accessories max.current 400 mA

Operating ambient temperature -20°C... +55°C

Fuses

F1 = self-resetting;

F2 = T2A-250V

or

T4A-120V

Function logics A, E, AP, EP,A1,B,C

Work time (time-out) 1 minute (maximum)

Pause time

Varies according to learning

(max. 10 min.)

Terminal board inputs

Open A, Open B, Stop, BUS

(I/O)

Connector inputs

Power supply, battery radio

module 3 pins

Terminal board outputs

Motors, fl ashing lamp, power

supply to accessories, electric

lock, service light contact (90

sec fi xed)

Programmable functions

Logic (A, E, AP, EP,A1,B,C),

Speed (High - Low)

Learning functions

Pause time,

leaf closing delay

The power supply and the fuse are related to the

purchased version.

Different output values can be obtained on the board

supply terminals depending on the mains voltage va-

lue. Before start-up always check if the output voltage

on the transformer secondary winding is between 20

Vac and 26 Vac. Voltage must be measured load free.

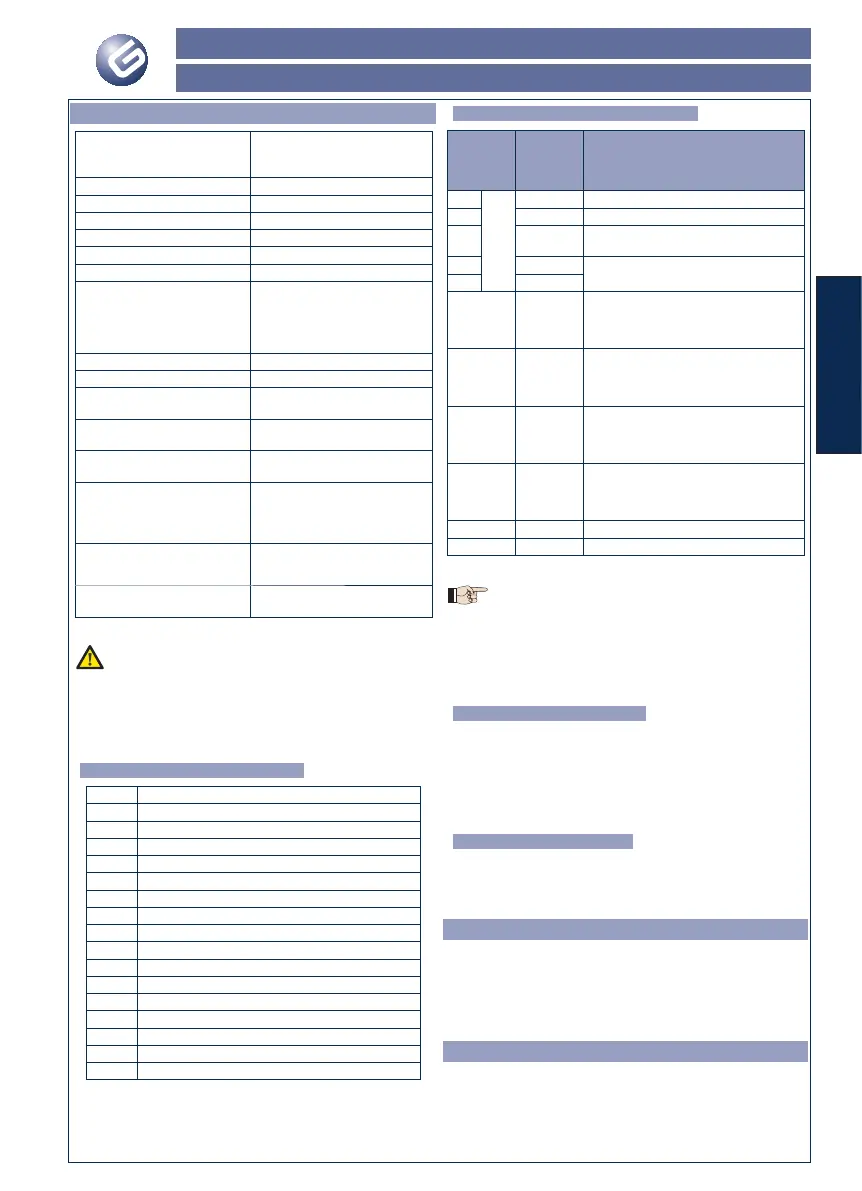

3.1. Description of components

J1 POWER SUPPLY connector

J2 SERVICE LIGHT command terminal-board

J3 FLASHING LAMP terminal-board

J4 ELECTRIC LOCK terminal-board

J5 COMMANDS terminal-board

J7 MOTOR 1 terminal-board

J8 MOTOR 2 terminal-board

J9 Rapid connection for RADIO MODULE 3 pins

J10 BUS terminal-board

J11 BATTERY connector

SW1 SET UP push-button

SW2 SPEED push-button

SW3 LOGIC push-button

DS1 Programming Dip-switch

F1 Accessories protective fuse

F2 Fuses protecting transformers and motors

LED Signalling LEDs

3.2. Description of terminal-boards

Terminal

and/or

terminal-

board

Descrip-

tion

Device connected

1

J5

+24V Power supply for accessories

2 GND Negative

3STOP

Device with NC contact which causes the

automated system to shut down

4 OPEN B

Device with N.O contact (see chap. FUN-

CTION LOGICS)

5 OPEN A

J10

RED

terminal

BUS Safety devices with BUS technology

J2

GREY

terminal

SERVICE

LIGHT

Service Light control output (connect a

relay coil at 24Vdc-100mA max)

J3

ORANGE

terminal

LAMP Flashing lamp 24Vdc - 15W

J4

BLUE

terminal

LOCK

Electric lock 12Vac or 24 Vdc (to be

installed on leaf 1)

J7 MOT1 Motor 1 (leaf 1)

J8 MOT2 Motor 2 (leaf 2)

The service light control is active as specifi ed in advanced

function 9 Table 4:

- for the entire opening and closing movement of the gate

and for a further 90 seconds (standard operation)

- when the gate is closed (closed status function)

Leaf 1 means the leaf which opens fi rst during the opening

operation.

3.3. Anti-crushing function

The electronic anti-crushing function is obtained by controlling the

current consumption or the encoder of the motors connected to

the BRAIN 15 equipment.

If the gate detects an obstacle during the opening or closing move-

ment, the anti-crushing function activates and reverses the sense

of direction of the operator, thus increasing the safety degree of

the automated system.

3.4. Over pushing stroke

If you enable this function, at every OPEN pulse the leaf on which the

electric lock is installed starts its closing movement for a few seconds.

This facilitate release of the electric lock.

4. PROGRAMMING OF THE LOGIC

Repeatedly press the SW3 LOGIC push-button to select one of the

7 programming logics available.

The selected logic is signaled by the LD7 LED:

The number of blinkings corresponds to the number of the se-

lected logic.

See paragraph 6.3.3.

5. PROGRAMMING THE SPEED

The function speed can be adjusted at any time by pressing

push-button SW2.

The selected logic is then displayed on LED LD8:

Led on = HIGH speed

Led off = LOW speed

Loading...

Loading...