ENGLISH

14

햲햲

햲햲

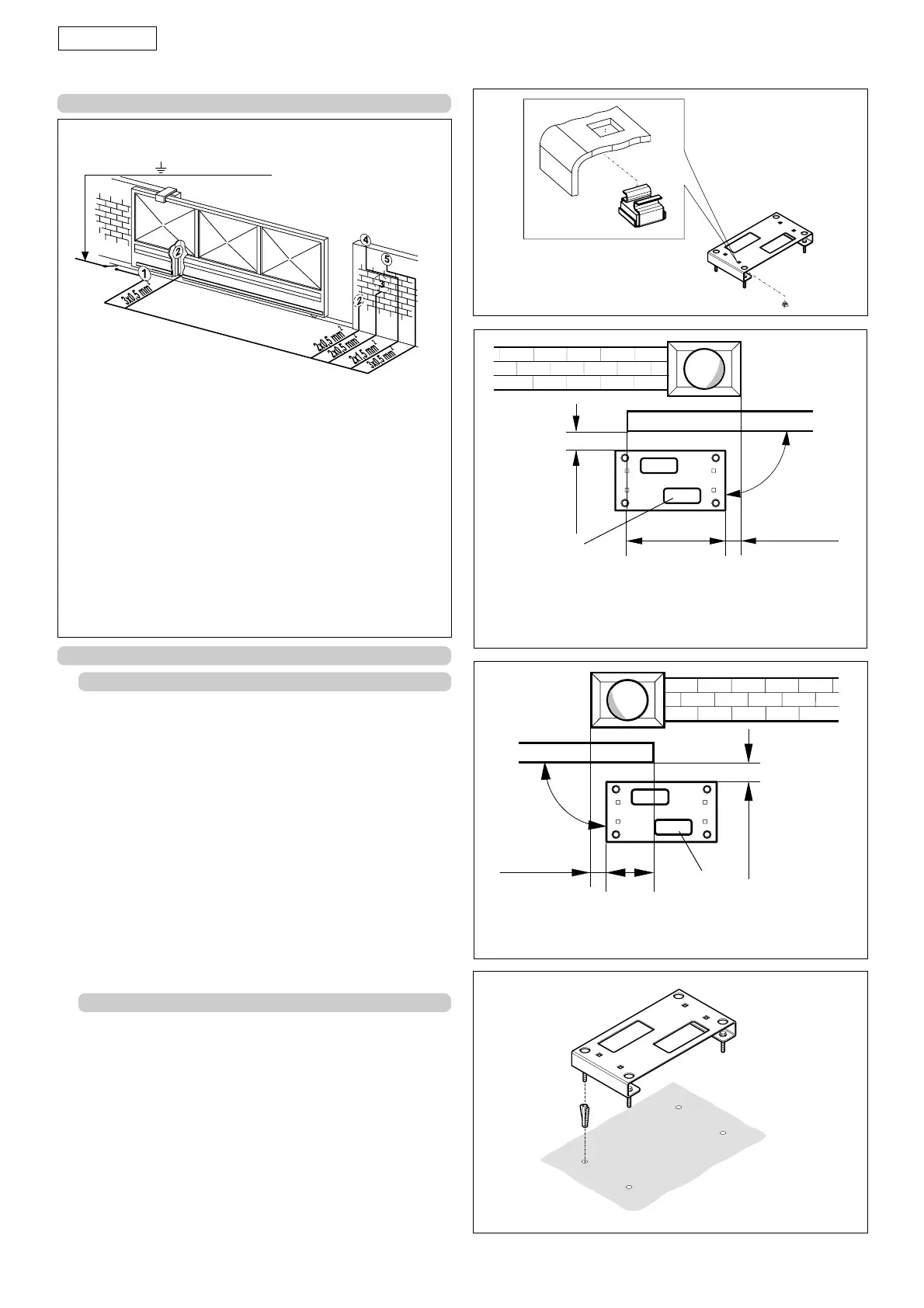

햲 Step operator with equipment.

햳햳

햳햳

햳 Photocells

햴햴

햴햴

햴 Key operated push-button

햵햵

햵햵

햵 Flashing lamp

햶햶

햶햶

햶 Radio receiver

Fig. 3

Notes: 1)To lay electric cables, use adequate rigid and/or

flexible tubes.

2)Always separate low voltage connection cables from

those operating at 230 Vac. To prevent any

interference whatever, use separate sheaths.

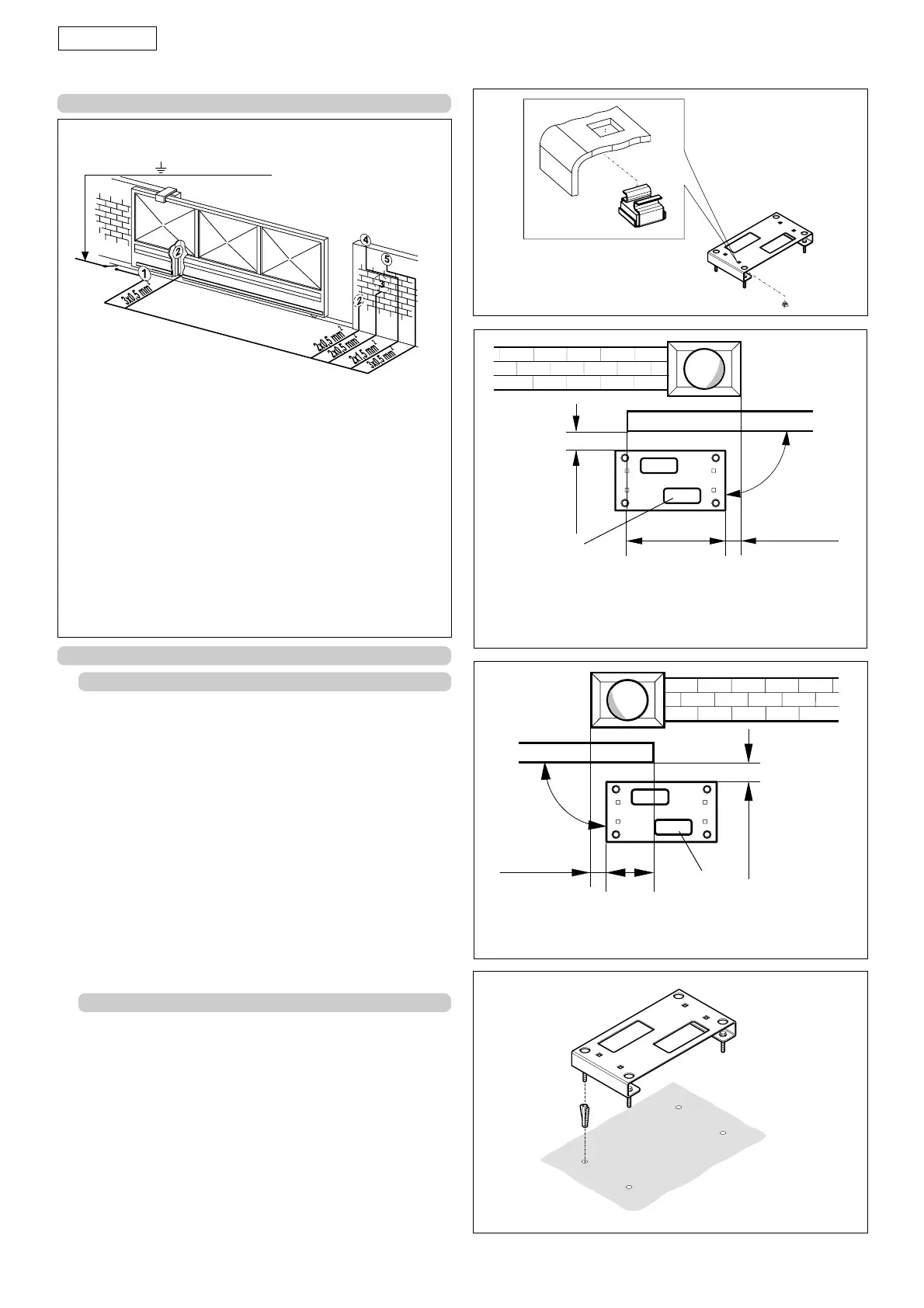

4.2. SECURING THE FOUNDATION PLATE

• Fit the 4 supplied caged nuts, as shown in figure 4, in the 4

square holes of the plate.

• The foundation plate must be located as shown in figure 5

(right closing) or figure 6 (left closing) to ensure the rack and

pinion mesh correctly.

• Secure the foundation plate to the floor, using adequate

expansion plugs (fig. 7) and provide one or more sheaths for

routing the electric cables. Using a spirit level, check if the

plate is perfectly level.

• Lay the electric cables for connection to the accessories and

power supply as shown in figure 3.

To facilitate making the connections, allow the cables to

project by about 20 cm from the hole (Fig.5-6 ref. 햲) of the

foundation plate.

4. INSTALLING THE AUTOMATED SYSTEM

4.1. PRELIMINARY CHECKS

To ensure safety and an efficiently operating automated system,

make sure the following conditions are observed:

• The structure of the gate must be suitable for it to be

automated. In particular, wheel diameter must be in relation

to the weight of the gate to be automated, and dimensions

and weight must match those indicated in the technical

specifications.

• Make sure that the gate slides without any inclination.

• Make sure that the gate moves uniformly and correctly,

without any irregular friction during its entire travel.

• The soil must permit sufficient stability for the expansion plugs

securing the foundation plate.

• Check if the upper guide and travel limit mechanical stops

are installed.

We advise you to have any metalwork carried out before the

automated system is installed.

3. ELECTRONIC EQUIPMENT (standard system)

Fig. 6

• Dimensions in mm

*Use the dimensions according to type of rack.

Galvanised rack 30x6 = 36.5

Galvanised rack 30x12 = 39.5

Nylon rack 30x20 = 41.5

Fig. 5

Fig. 7

Fig. 4

햲

햲

*

*

• Dimensions in mm

*Use the dimensions according to type of rack.

Galvanised rack 30x6 = 36.5

Galvanised rack 30x12 = 39.5

Nylon rack 30x20 = 41.5

36,5

÷

41,5

175,5

0

÷

50

90

°

36,5

÷

41,5

0

÷

50

90,5

90

°

2x1,5 mm + (230Vac)

2

Loading...

Loading...