ENGLISH

15

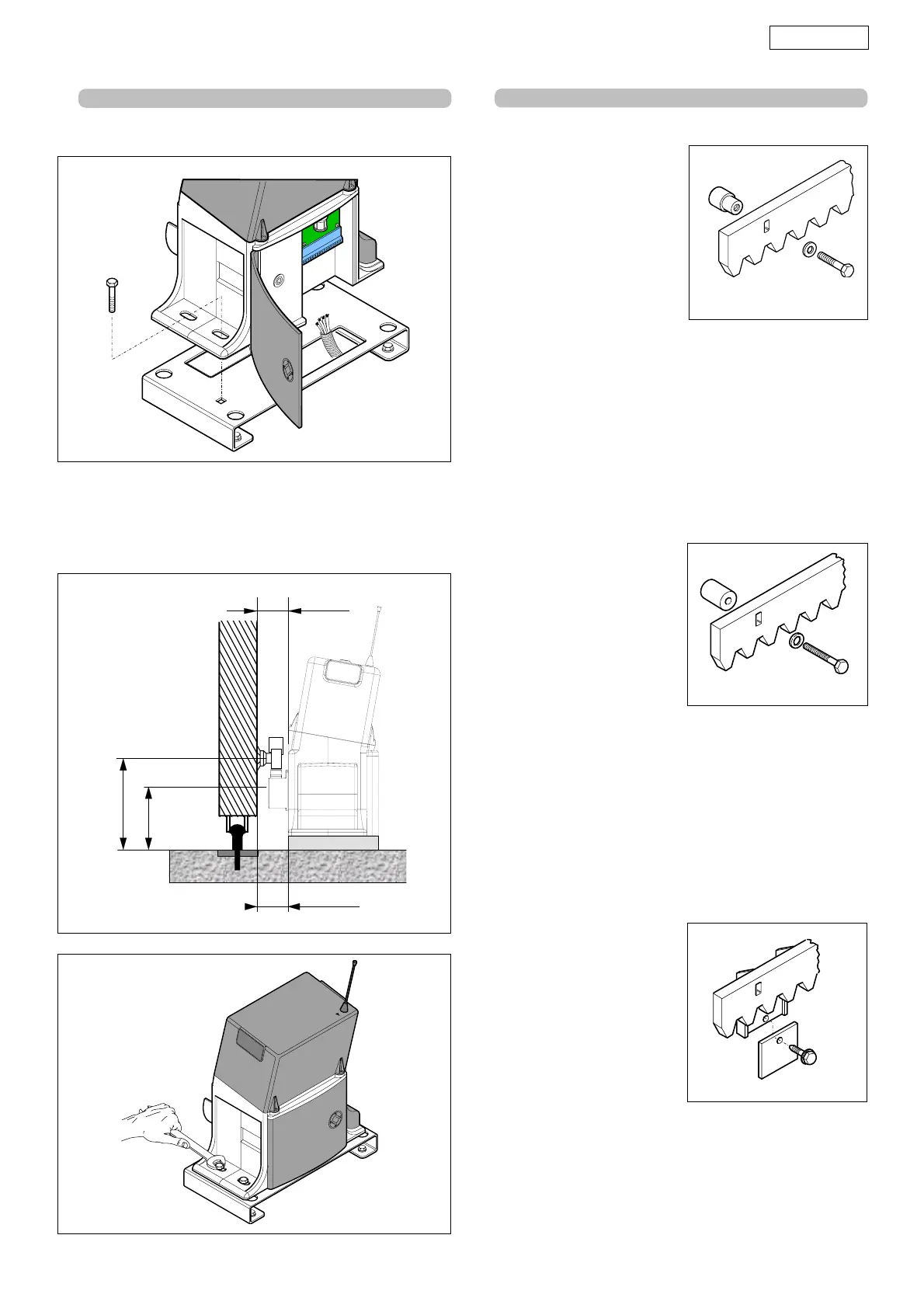

• Position the operator on the plate, using the supplied screws

as shown in figure 8.

Fig. 8

Fig. 9

4.3. MECHANICAL INSTALLATION

• Adjust the distance of the operator from the gate by referring

to fig. 9.

• Secure the gearmotor to the foundation plate, tightening

the screws as in Fig.10.

• Prepare the operator for manual operating mode as

described in chapter 13.

4) Move the gate manually, checking if the rack is resting on the

pinion, and weld the second and third pawl.

5) Bring another rack element near to the previous one, using

a piece of rack (as shown in figure 15) to synchronise the teeth

of the two elements.

6) Move the gate manually and weld the three threaded

pawls, so proceeding until the gate is fully covered.

Fig. 12

4.4.2. STEEL RACK TO BE SCREWED (Fig.12)

1) Manually take the leaf into

its closing position.

2) Lay the first piece of rack at

the appropriate level on the

pinion and place the spacer

between rack and gate,

positioning it at the top of

the slot.

3) Mark the hole position on

the gate. Drill a Ø 6.5 mm

hole and thread with a Ø 8

mm tap.

Screw the bolt.

4) Move the gate manually,

checking if the rack is resting on the pinion, and repeat the

operations at point 3.

5) Bring another rack element near to the previous one, using

a piece of rack (as shown in figure 15) to synchronise the teeth

of the two elements.

6) Move the gate manually and carry out the securing

operations as for the first element, proceeding until the gate

is fully covered.

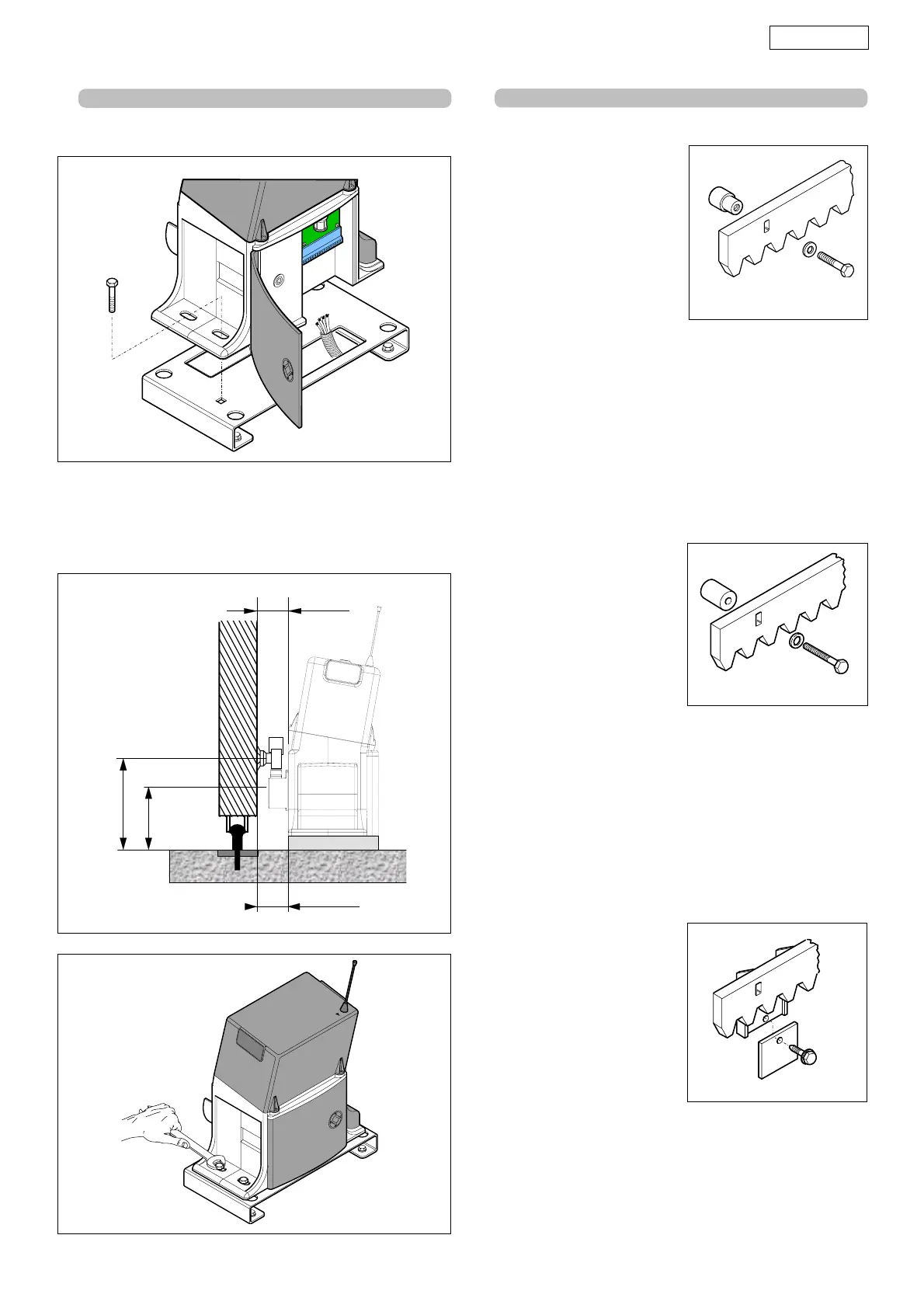

4.4.3. NYLON RACK TO BE SCREWED (Fig.13)

Fig. 13

a piece of rack (as shown in figure 15) to synchronise the

teeth of the two elements.

5) Move the gate manually and carry out the securing

operations as for the first element, proceeding until the

gate is fully covered.

1) Manually take the leaf into its

closing position.

2) Lay on the pinion the first piece

of rack at the appropriate

level and mark the hole

position on the gate; make a

hole with a 4 mm bit and

screw the 6x20 mm self-

tapping screw with reinforcing

plate.

3) Move the gate manually,

checking if the rack is resting

on the pinion, and repeat

the operations at point 2.

4) Bring another rack element

near to the previous one, using

Fig. 10

Fig. 11

4.4. INSTALLING THE RACK

4.4.1. STEEL RACK TO BE WELDED (Fig. 11)

1) Place the three threaded

pawls on the rack element,

positioning them at the top

of the slot. In this way, the slot

play will enable any

adjustments to be made.

2) Manually take the leaf into

its closing position.

3) Lay the first piece of rack at

appropriate level on the

pinion and weld the

threaded pawl on the gate

as shown in figure 14.

46,5÷51,5

112,5÷146

106

36,5÷41,5

Loading...

Loading...