23

GB

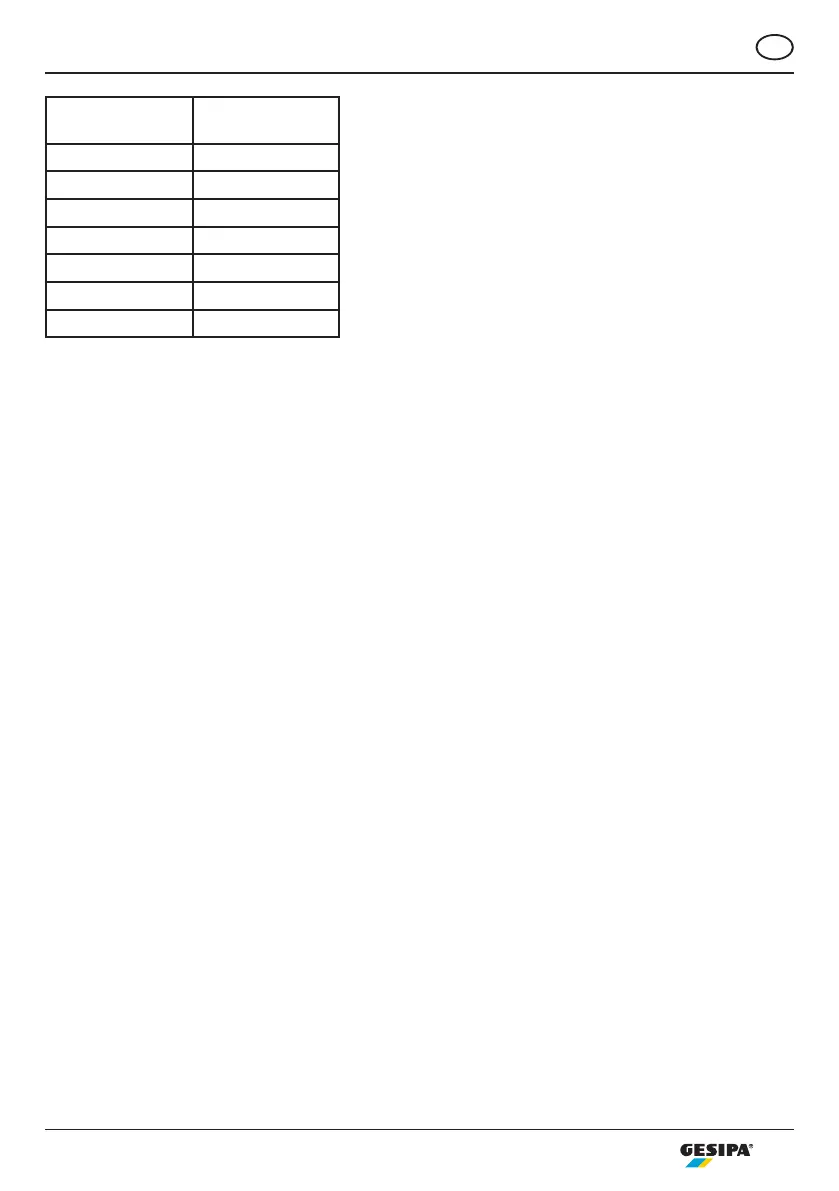

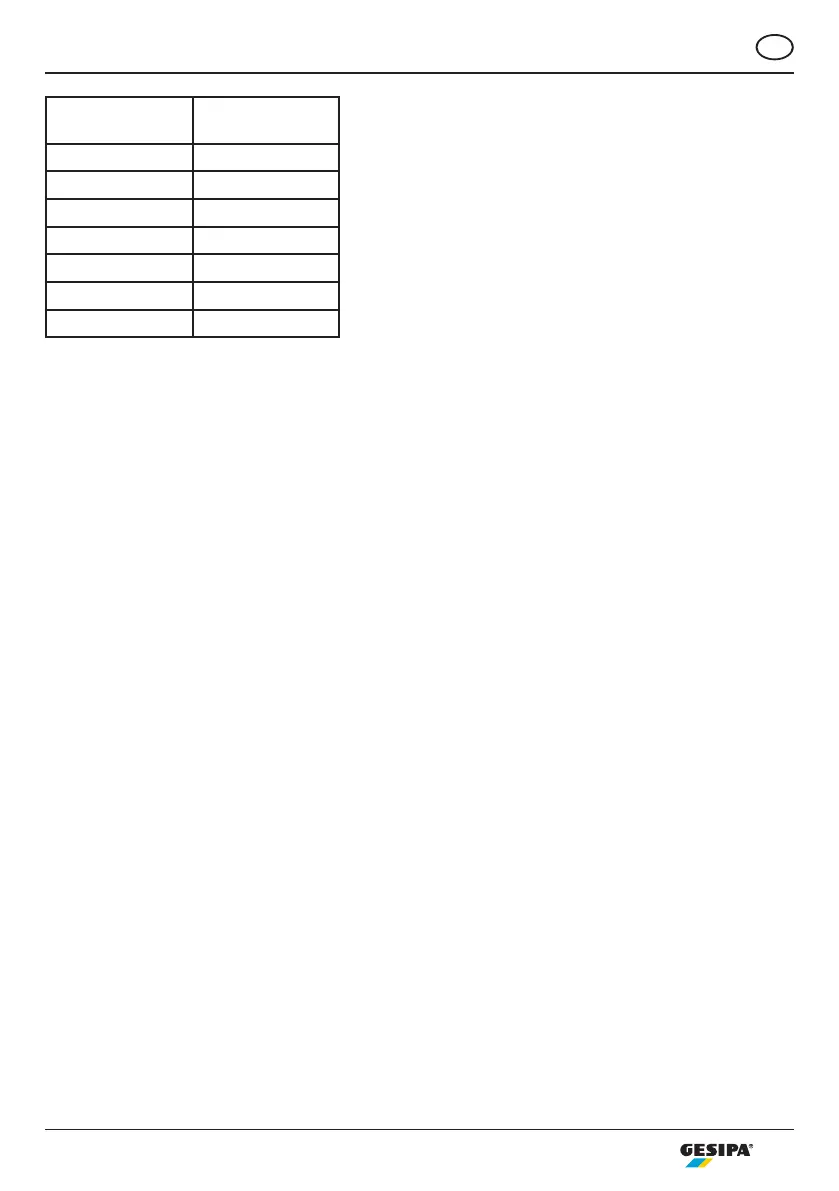

Thread size

Setting stroke*

guide values

M3 2

M4 2,5

M5 3

M6 3,5

M8 4

M10 5

M12 5

ATTENTION! If the setting stroke is unknown, rst set a lower setting stroke to prevent dama-

ge to the thread. If the nut is not sufciently set, increase the setting stroke in a small steps

(max. 0.5 mm; half a turn of the adjusting nut). If too large a setting stroke has been set and

the thread of the blind rivet nut is damaged, it must be unscrewed manually (see point 4.2).

*Guideline values determined with GESIPA

®

standard dome head blind rivet nuts for a grip

range of 0.25-3 mm in 1 mm material thickness.

4. Functional principle

4.1 Screwing on a blind rivet nut

• Ensuring it is straight, set the blind rivet nut against the threaded mandrel A.

• It is advisable to screw in the blind rivet nuts manually by around a ½ turn to make it

easier to insert through the threaded mandrel A.

• Start the screw-in sequence by pressing the switch G.

• Hold down the switch G until the screw-in sequence is stopped automatically. While doing

this, hold the blind rivet nut secure against twisting during the entire screw-in sequence.

The blind rivet nut must be correctly positioned on the nosepiece B after the screw-in se-

quence. Otherwise, correct the setting of the threaded mandrel length (see Section 3.2)..

Caution: If the switch is released prematurely, the nut will be screwed off again.

Loading...

Loading...