32

LRR 1-50, LRR 1-51 - USA - Installation & Operating Manual - 850702-01

Attention

Please check the following before fault diagnosis:

Supply voltage:

Is the conductivity controller supplied with the voltage specified on the rating plate?

Wiring

Does the wiring conform to the wiring diagram?

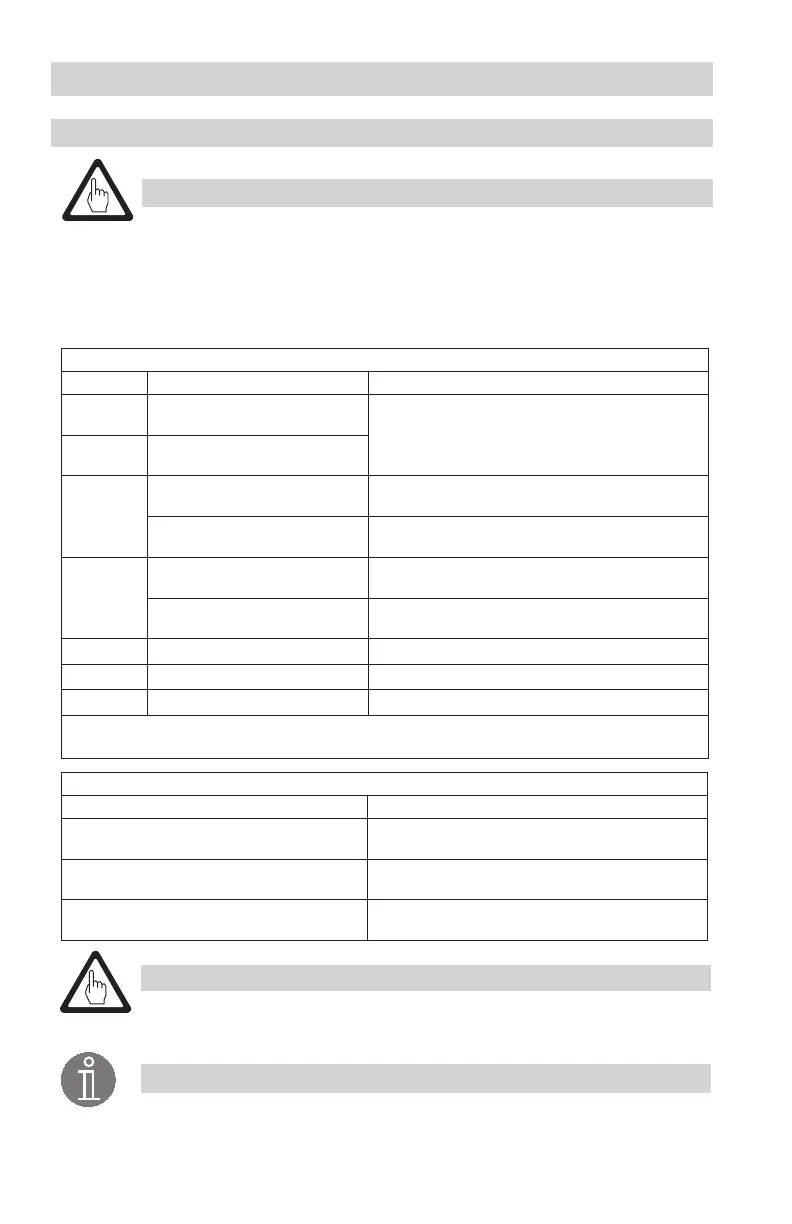

Fault indications and troubleshooting

Indications, diagnosis and corrective action

Attention

■ For further troubleshooting, please refer to the LRG 16-4, LRG 16-9 and LRGT

1.-.. Installation & Operating Manuals.

Note

In the event of a fault in the conductivity controller, the MAX alarm is triggered and

the equipment restarts. If the process repeats itself continuously, the equipment

must be replaced.

Error codes on the 7-segment display

Error code Error Corrective action

E.001

Faulty temperature sensor,

temperature reading too low

Check resistance thermometer and LRG 16-9 conduc-

tivity electrode and replace if necessary. Check electri-

cal connection (short circuit, open circuit?).

E.002

Faulty temperature sensor,

temperature reading too high

E.005

Faulty conductivity electrode,

reading too low.

Check conductivity electrode and replace if necessary.

Check electrical connection.

Faulty conductivity transmitter,

measuring current < 4mA

Check conductivity transmitter and replace if neces-

sary. Check electrical connection.

E.006

Faulty conductivity electrode,

reading too high.

Check conductivity electrode and replace if necessary.

Check electrical connection. Check boiler water.

Faulty conductivity transmitter,

measuring current > 20mA

Check conductivity transmitter and replace if neces-

sary. Check electrical connection.

E.097 Walkthrough application error Internal error. Replace equipment.

E.098 Walkthrough test error Internal error. Replace equipment.

E.099 Internal test error Internal error. Replace equipment.

In the event of a fault, the MAX alarm is triggered and the continuous blowdown valve moves into

OPERATING position.

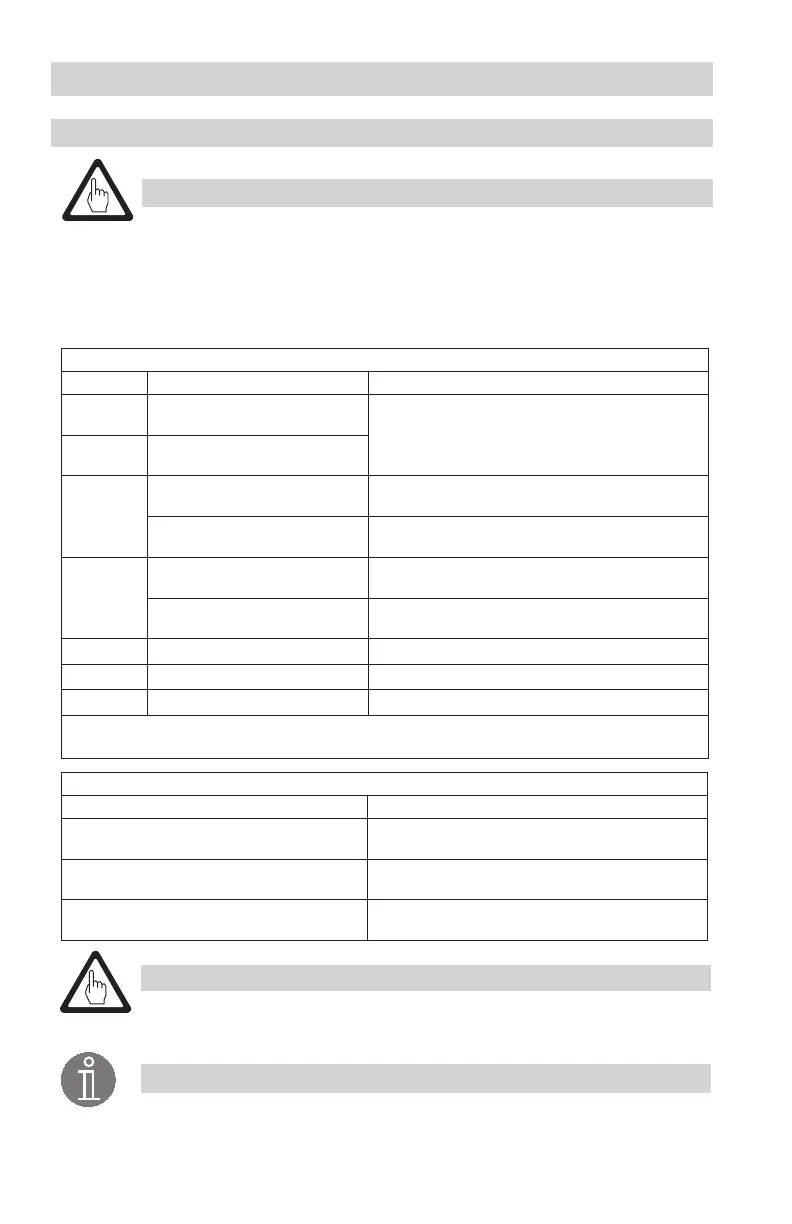

Errors without an error code

Error Corrective action

Actual value < set point. Continuous blowdown

valve opens.

Check code switch S4. Switch must be in the ON

position.

4-20 mA actual value display remains in the 4-8

mA or 20 mA range when the conductivity changes

Check code switch S3 with the help of the table

on p. 19. Switch must be in the OFF position

4-20 mA manipulated variable output (Yw)

changes proportional to conductivity.

Check code switch S3 with the help of the table

on p. 19. Switch must be in the ON position

Loading...

Loading...