4

E.04.99 • G. 13.11.07

Overview

Operating instructions

The operating instructions together with this technical information leaflet must be displayed in a clearly vi-

sible position in the boiler room. It is essential to write the address of the nearest customer service centre

in the operating instructions.

Instruction of operating personnel

Faults are often caused by operator error. The operating personnel must be properly instructed in how the

burner works. In the event of recurring faults, Customer Service should be notified.

Maintenance and customer service

The complete system should be checked once a year for correct functioning and leaks by a representative

of the manufacturer or other suitably qualified person.

We accept no liability for consequential damage in cases of incorrect installation or repair, the fitting of non-

genuine parts or where the equipment has been used for purposes for which it was not intended.

Key for code designation

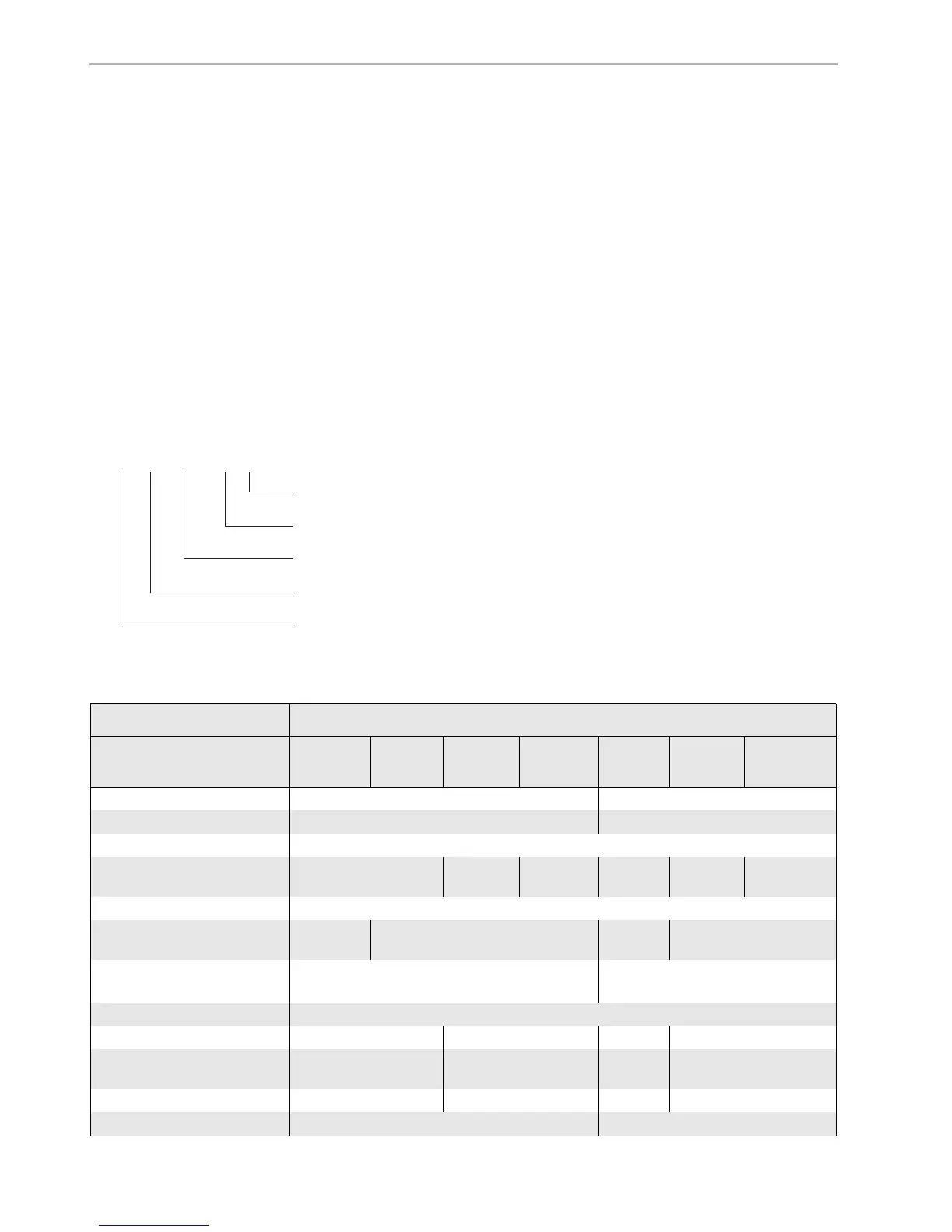

Technical specifications

Burner type

Technical data

RG20-N

(-F)

RG20-L

-N(-F)

RG20-Z

-L-N(-F)

RG20

-M-L-N

RG30-N

(-F)

RG30-Z

-L-N(-F)

RG30

-M-L-N(-F)

Min. burner output in kW 40 105

Max. burner output in kW 120 260

Gas type for natural gas LL + E = “-N” / LPG 3B/P = “-F”

Method of operation 1-stage 2-stage

sliding

modulating 1-stage 2-stage

sliding

modulating

Voltage 1 / N / PE ~50 Hz - 230 V

Max. current consumption

Max. start / operation 1.48A/0.75A 1.35A/0.72A 3 A/1.4 A 3.1 A/1.5 A

Electric motor power

(at 2850 rpm

-1

) in kW

0.14 0.25

Flame failure controller Ionisation electrode

Control box DMG 970 DMG 972 DMG 970 DMG 972

Air pressure monitor DL 2E - 150 Pa DL 2E - 40 Pa DL 2E

- 150 Pa

DL 2E - 40 Pa

Weight in kg 26 29 38 40

Noise emission in db(A) ≤72 ≤ 75

Loading...

Loading...