10

Fine Aggregates

The Testing Screen is designed primarily for operation in

the coarse size range of 4in to No.4. Separation of ner

materials is less ecient and ne particles may become

trapped behind side liners of trays causing test errors�

For separations of ne aggregates from No.8 through

No�200, loading at completion of sieving should be limited

to the ASTM C 136 level of 4g per square inch of sieving

surface, assuming a material about the density of sand�

This is equivalent to loading 1,350g (3lb) per tray and will

result in machine capacity in the ne aggregate range of

under 20lb per test unless sizes are evenly distributed

among the trays�

Somewhat larger amounts of material may be loaded if the

Testing Screen is used for mass separation rather than for

testing� Sharpness of separation will decrease as loading

is increased, and overloads can cause damage to valuable

wire cloth�

For applications where test materials are limited to ne

series sizes, or where special screening problems exist-

because of softness or density, the Testing Screen may be

factory-equipped with a Speed Variation Accessory�

A low-amplitude eccentric shaft is also available and rec-

ommended when working exclusively with friable materials�

The capacity of the Gilson Testing Screen is suitable for

most laboratory test sizing work. For eld laboratories

where mobility is important, Gilson oers a Porta-Screen

®

�

For large-scale mass separation jobs involving hundreds

of pounds of material, and for automated testing, use the

Gilso-Matic

®

Screening Assemblies� See the Gilson Catalog

for further information�

Maintenance

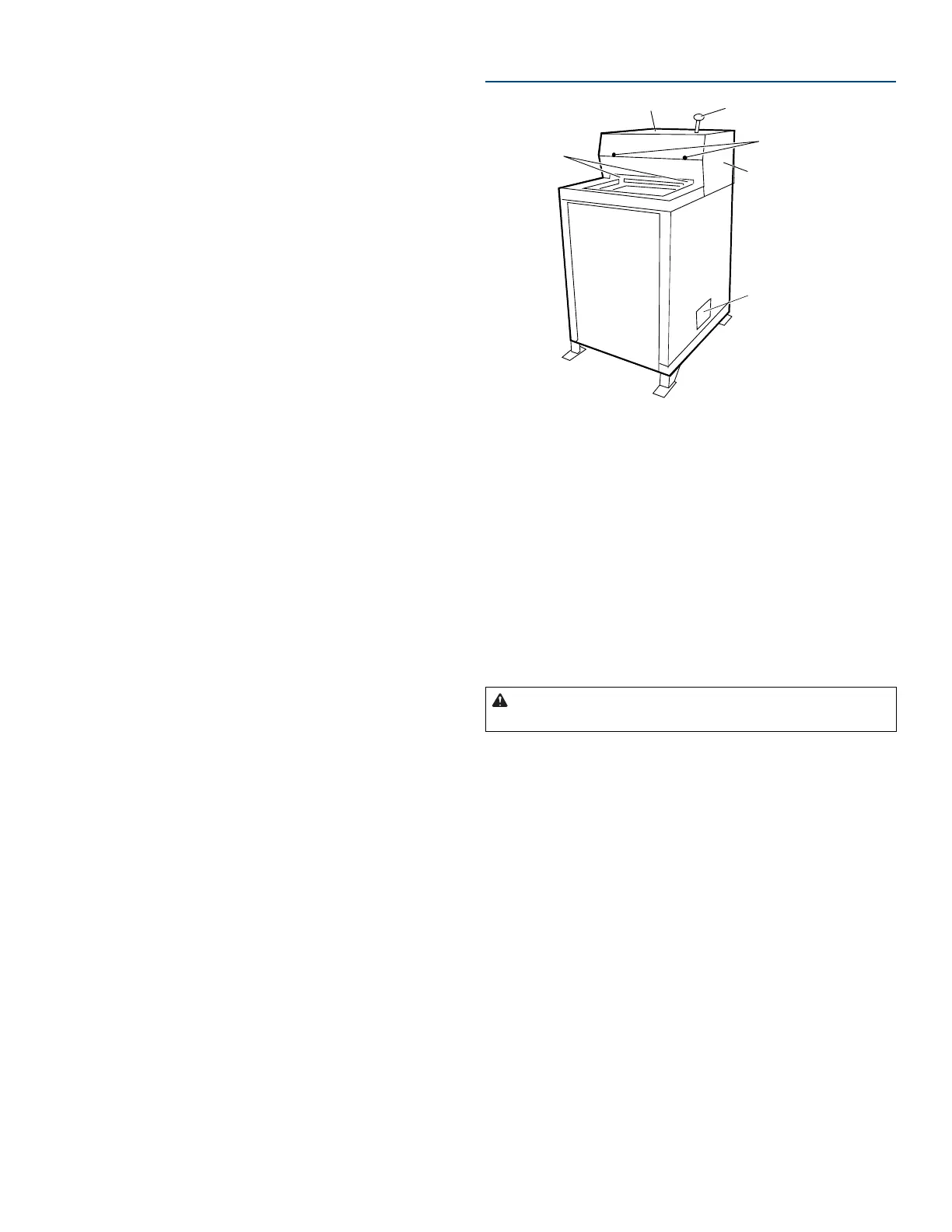

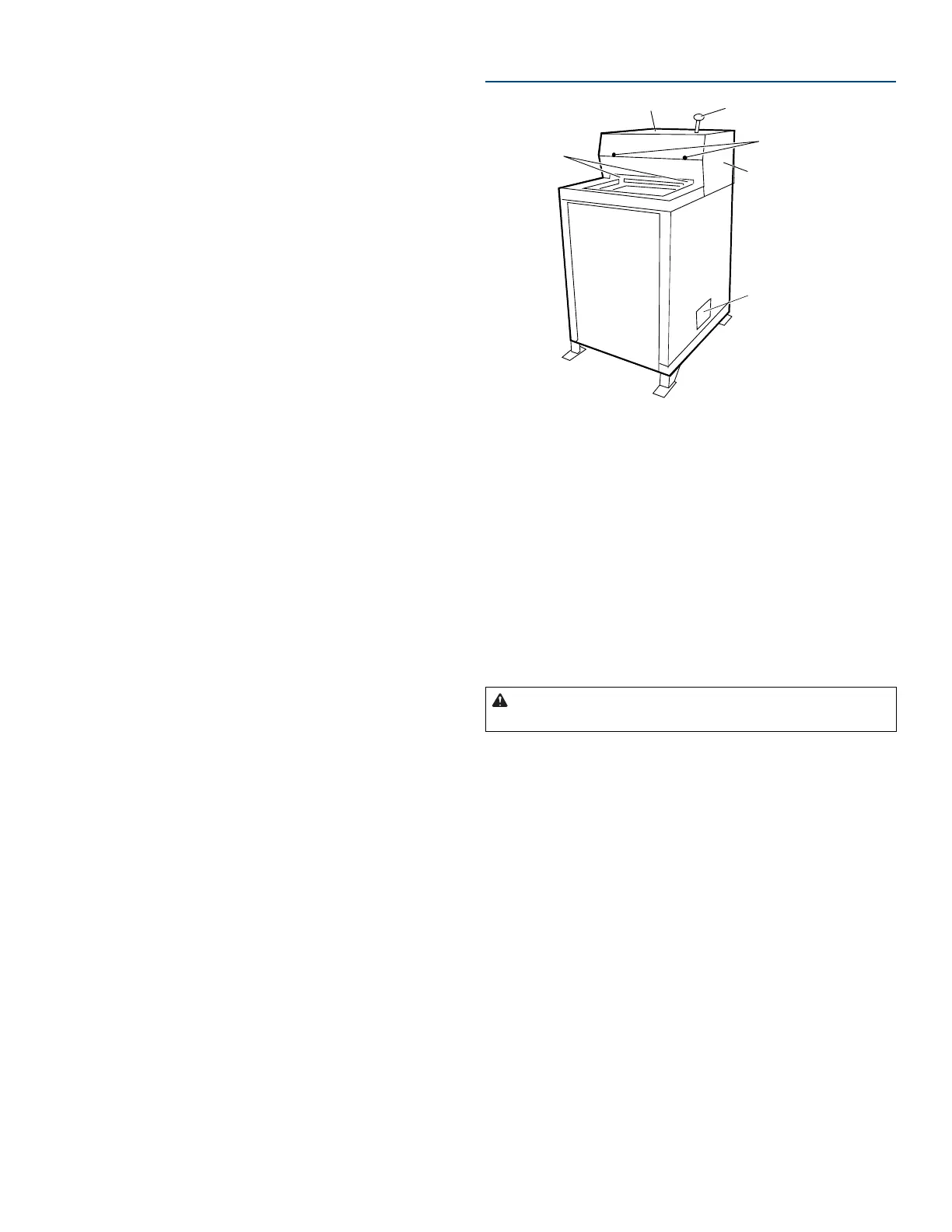

Upper Connecting

Rod Bearings Access

Lower Connecting

Rod Bearings

Access

Lower Threaded Block

/Bearing Access

Top Cover

Pump Handle

Side/Back Cover

Fig. 4: Lubrication Access

NOTE: The person performing maintenance and/or

repairs on the Testing Screen is responsible for

safety and is required to read and understand the

safety instructions in this manual prior to commenc-

ing work�

All shields, guards and other safety devices must be prop-

erly replaced and secured upon completion of work� Only

parts supplied and/or approved by Gilson are acceptable

for use on the machine�

Lubrication

Disconnect power supply before

servicing or cleaning.

Most sample dusts are abrasive by nature� Daily lubrica-

tion and cleaning of the Testing Screen takes only a few

minutes, and will greatly extend its service life and reduce

down time�

Each Testing Screen is fully lubricated and test-run by

the manufacturer before it is shipped� However, periodic

lubrication is required�

Use a high-quality grease to lubricate the parts listed below�

Wipe away excess grease and dirt from around parts

after lubrication�

Wrist Pin Assemblies

At least daily, lubricate the wrist pin assemblies at the lower

ends of the connecting rods (Fig� 4)�

Access: Slot under front of top cover�

Loading...

Loading...