11

Lubricate the following parts on a regular basis, but not as

often as the wrist pin assemblies:

Upper Connecting Rod Bearings

Access: Holes in front of top cover�

Lower threaded blocks (TS-2 Only)

Access: Panels on sides of machine case�

Removal of Top and Side/Back Covers

Disconnect power supply before

servicing or cleaning.

DO NOT plug in or operate the

Testing Screen without all covers installed.

TS-1/TS-3: Unscrew the knob on the pump handle�

Remove the thirteen screws that secure the top cover,

then remove the cover� Reinstall the knob�

TS-2: Turn the clamp rod handles so they point sideways

and away from the machine� Remove the thirteen screws

that secure the top cover, then remove the cover�

TS-1, TS-2, TS-3: Loosen or remove the ve screws that

secure the side/back cover� Pivot the cover toward the back

of the machine, allowing it to be supported by the motor

wire�

Drive Assembly

Disconnect power supply before

servicing or cleaning.

DO NOT plug in or operate the

Testing Screen without all covers installed.

V-belt

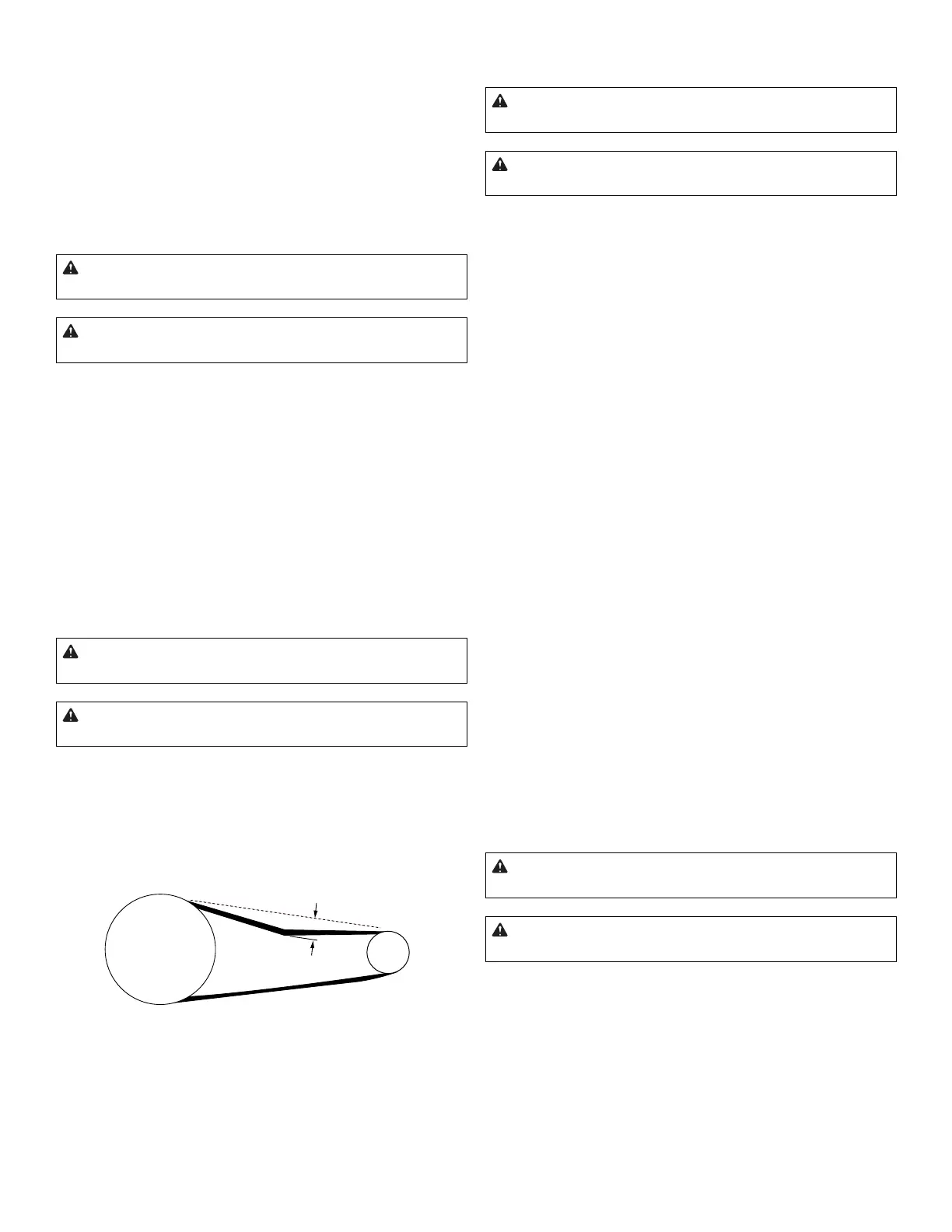

Periodically check the motor V-belt for wear, tension, and

alignment� The belt should be snug, neither too tight nor

too loose. It should deect about 1/4in (6mm) at the center

point between the pulleys (Fig� 5)�

1/4” (6mm)

Fig. 5: Correct V-belt tension

A worn, loose, tight, or misaligned V-belt can adversely af-

fect the operation of the Testing Screen. A good t assures

longer life, less bearing wear, and quieter operation than a

belt which is too tight� A loose belt may cause the machine

to run too slowly or to slip�

Adjust or Replace the V-belt

Disconnect power supply before

servicing or cleaning.

DO NOT plug in or operate the

Testing Screen without all covers installed.

1. Remove the top and side/back covers�

2. Loosen the motor mounting bolts�

3. Verify that the pulleys are aligned and adjust if

necessary� Move the motor until the correct belt tension

is obtained (Fig� 5)�

4. Tighten the motor mounting bolts then re-verify the

belt tension�

V-belt Replacement

1. Loosen the motor mounting bolts and move the motor

toward the front of the machine until the belt disengages

from the motor pulley�

2. Insert a pry bar under the front of the case top and

over the top of the Vibrating Unit Assembly� Shift the

Vibrating Unit Assembly until the holes in the Vibrating

Unit Assembly and in connecting rod align� Remove the

shoulder bolt�

3. Rotate connecting rod upward until you can remove

the belt�

4. Install the new V-belt around the connecting rod�

5. Replace the shoulder bolt then place the V-belt around

the pulleys� Make sure that the pulleys are aligned�

6. Move the motor toward the rear of machine until the

correct belt tension is obtained (Fig� 5)� Tighten the

motor mounting bolts then re-verify the belt tension�

Connecting Rod Assembly

Disconnect power supply before

servicing or cleaning.

DO NOT plug in or operate the

Testing Screen without all covers installed.

Gilson recommends replacing the connecting rods as com-

plete assemblies to avoid t and tolerance problems during

installation� Use the following procedure:

Loading...

Loading...