8

3. Apply clamping force to hold the screen tray that extends

from the front of the Testing Screen�

TS-1/TS-3: Apply short strokes to the hydraulic

pump handle�

TS-2: Turn the two clamp rods simultaneously and as

equally as possible, using your sense of touch to determine

when the trays are rmly clamped.

4. Place a level on the protruding screen tray then re-level

the Testing Screen by adding or removing shims until

the Vibrating Unit Assembly and screen tray are level

side-to-side and front-to-back. Give mounting nuts a nal

tightening�

5. Release clamping pressure and put desired screen trays

into the machine�

Hydraulic System Check

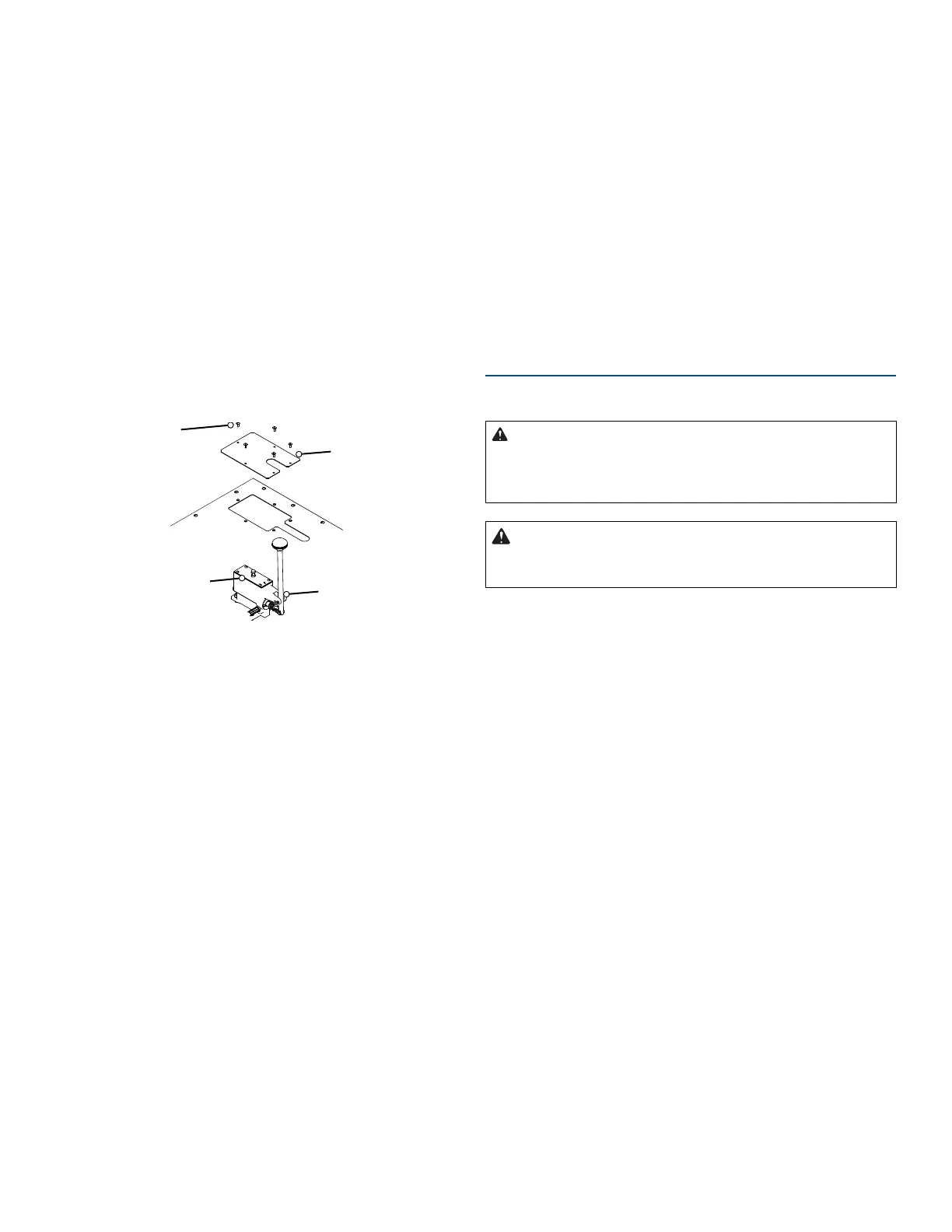

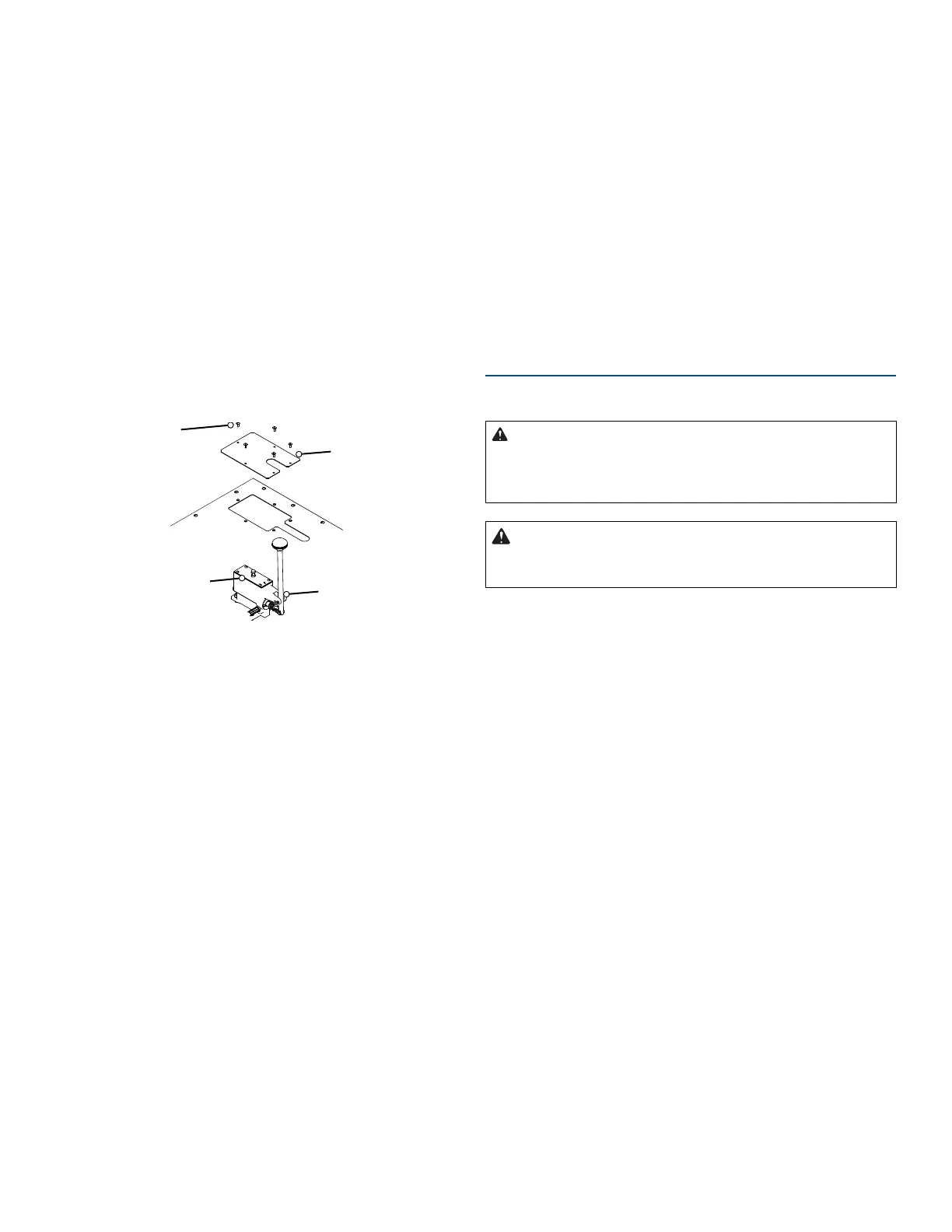

Screws (5x)

External

Pump

Cover

Pump

Cover

Hydraulic

Pump

Fig. 3: TS-1/TS-3 Hydraulic Pump Access

If you have a TS-1 or TS-3 Hydraulic Testing Screen,

examine and test the hydraulic system for leaks�

1. Remove the ve screws that secure the external pump

cover to the top, then lift the cover o (Fig. 3).

2. Observe the position of the internal pump cover before

you remove it� Its vent is slightly closer to the front

(handle) end of the pump than to the back� Gilson

recommends using a marker or other means to mark the

operator side of the cover to ensure correct orientation

during reassembly�

3. Check the oil level in the pump� It should be 1/4in from

the top of the reservoir� If not, refer to instructions for

replacing hydraulic oil on page 14� Reinstall the external

pump cover�

Verify Power Requirements

Verify that the Testing Screen is wired as ordered and

appropriate for your power source�

Standard Testing Screens are driven by a 115V/60Hz,

1/2hp electric motor requiring 12-15 amps to operate.

A dedicated 20 amp circuit is recommended. Machines

with model numbers ending in “F” are congured to

operate on 230V/50Hz.

• Locate the voltage label on the back of the Testing

Screen, and check to be sure that the machine is wired

as ordered�

• Make sure your electrical power source is of a like

conguration.

• Make sure the Testing Screen and your electrical power

source are properly grounded�

• Make sure the power switch (located on right, vertical

surface of the top cover) is in the OFF position�

Testing Screen Power OFF:

• GREEN button OUT

• RED button IN

Operation

TS-1/TS-2/TS-3 Operation

Read and understand ALL of the

safety and operating instructions and sample capac-

ity information in this manual before operating the

Testing Screen.

DO NOT wear loose clothing which

can get caught on the clamp rods while making this

adjustment.

NOTE: These instructions cover operation of the Testing

Screen, not performance of any test�

1. Locate the Testing Screen’s power switch on the right,

vertical surface of the top cover�

Make sure that the switch is in the OFF position:

• GREEN button OUT

• RED button IN

Plug the three-pronged plug into a properly-grounded

power source; or otherwise properly ground your Testing

Screen�

2. Release the clamping force of the Vibrating Unit

Assembly:

TS-1/TS-3: Pull the hydraulic pump handle all the way

toward the front of the machine�

TS-2: Turn clamp rods counterclockwise�

3. Load the Testing Screen:

Load your desired sequence of screen trays into your

Testing Screen, being careful not to pinch your ngers with

already inserted screen trays� Apply clamping force on the

trays�

TS-1/TS-3: Apply short strokes to the hydraulic pump han-

dle� The hydraulic system will apply tension on both sides

of the Vibrating Unit Assembly�

Loading...

Loading...