7

Lag screw mounting

Mounting hardware is not provided� These additional items

are required for proper lag screw installation on a poured

concrete oor:

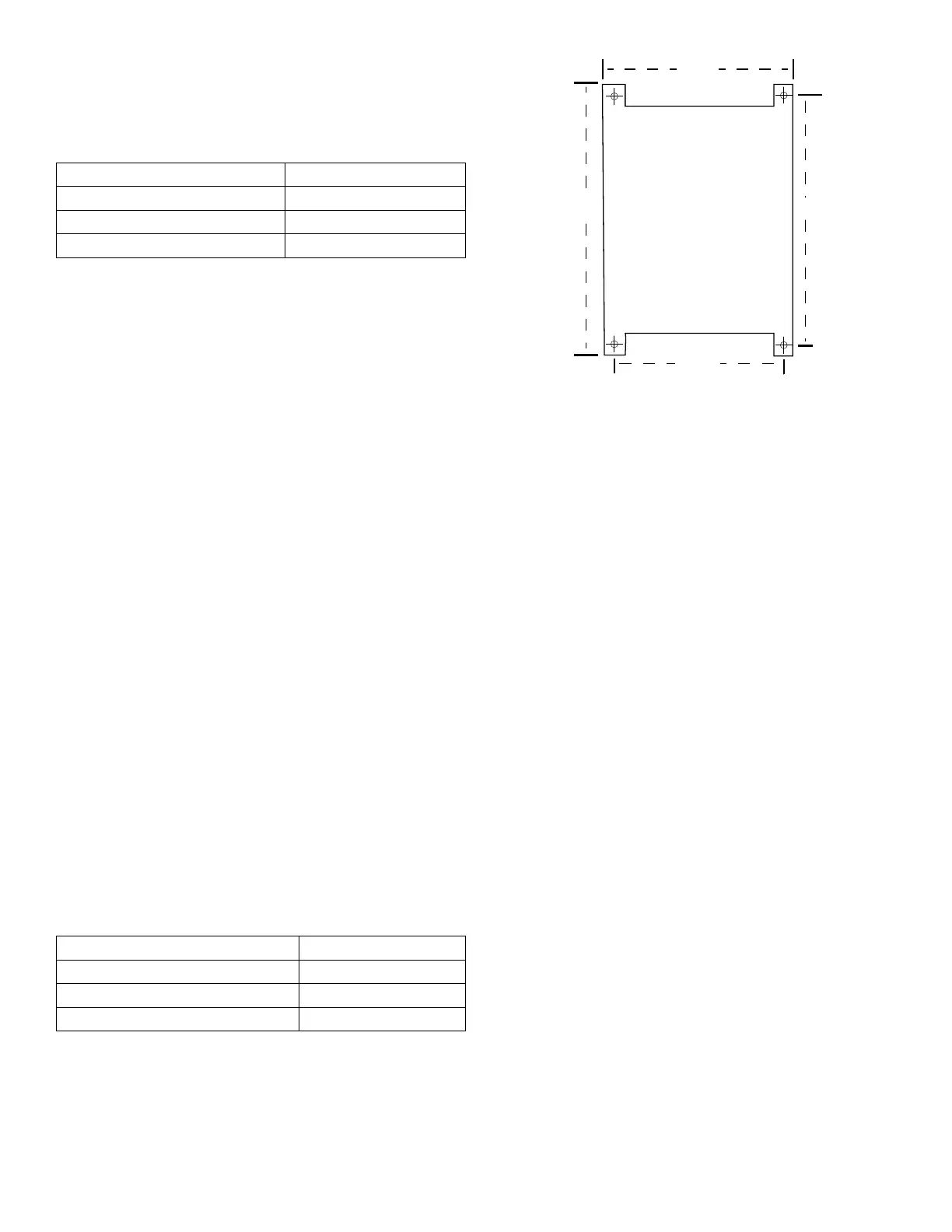

Hardware Quantity

0�5in lag screws 4

0�5in lag shield anchor 4

Metal shims Varies

Procedure

1. Place the unit in the desired location. Mark the oor in

the center of the mounting feet�

2. Using lifting equipment, move the unit�

3. Conrm marked mounting location matches the

mounting template (Fig� 2)�

4. Install the lag screw shield anchors in the marked

locations�

5. Using lifting equipment, return the unit to the mounting

location�

6. Place a at washer on the lag bolts and install the lag

screws in the mounting anchors� Do not fully tighten the

screws�

7. Initially level the units’ outer case, both front-to-back and

side-to-side� Do this by placing and/or removing metal

shims under the feet until the top of the unit is level along

all four edges�

NOTE: The Testing Screen must be level for proper test

results and best operation of the machine�

8. Tighten the lag bolts equally on all four mounting feet,

making sure the unit’s case remains level�

Anchor bolt mounting

Mounting hardware is not provided� These additional items

are required for proper anchor bolt installation on a poured

concrete oor:

Hardware Quantity

0�5in anchor bolts 4

0�5in lock nuts 4

Metal shims Varies

Procedure

1. Place the unit in the desired location. Mark the oor in

the center of the mounting feet�

2. Using lifting equipment, move the unit�

3. Conrm marked mounting location matches the

mounting template (Fig� 2)�

4. Install the anchor bolts in the marked locations, leaving

1�5in of thread exposed to allow for the mounting feet,

shims, and nuts�

5. Using lifting equipment, place the unit on the anchor

bolts, so that the threads extend through the holes in the

mounting feet�

6. Place mounting nuts on the anchor bolts to protect the

threads while leveling� Use lock nuts or other appropriate

locking fastener�

7. Initially level the units’ outer case, both front-to-back and

side-to-side� Do this by placing and/or removing metal

shims under the feet until the top of the unit is level along

all four edges�

NOTE: Note: The Testing Screen must be level for proper

test results and best operation of the machine�

8. Tighten the mounting nuts equally on all four mounting

feet, making sure the unit’s case remains level�

Level the Vibrating Unit Assembly

1. Release the clamping force:

TS-1/TS-3: Pull the handle on the hydraulic pump all the

way toward the front of the machine to release hydraulic

clamping force� Remove the screen trays

if present�

TS-2: Turn the manual screw-type clamp rods counter-

clockwise to release clamping force� Remove the screen

trays if present�

2. Insert a screen tray into the third screen tray position

from the top of Vibrating Unit Assembly, leaving 1/3 of its

length extended out of the front of the machine�

34” 32”

20.50”

Fig. 2: Mounting Template

Loading...

Loading...