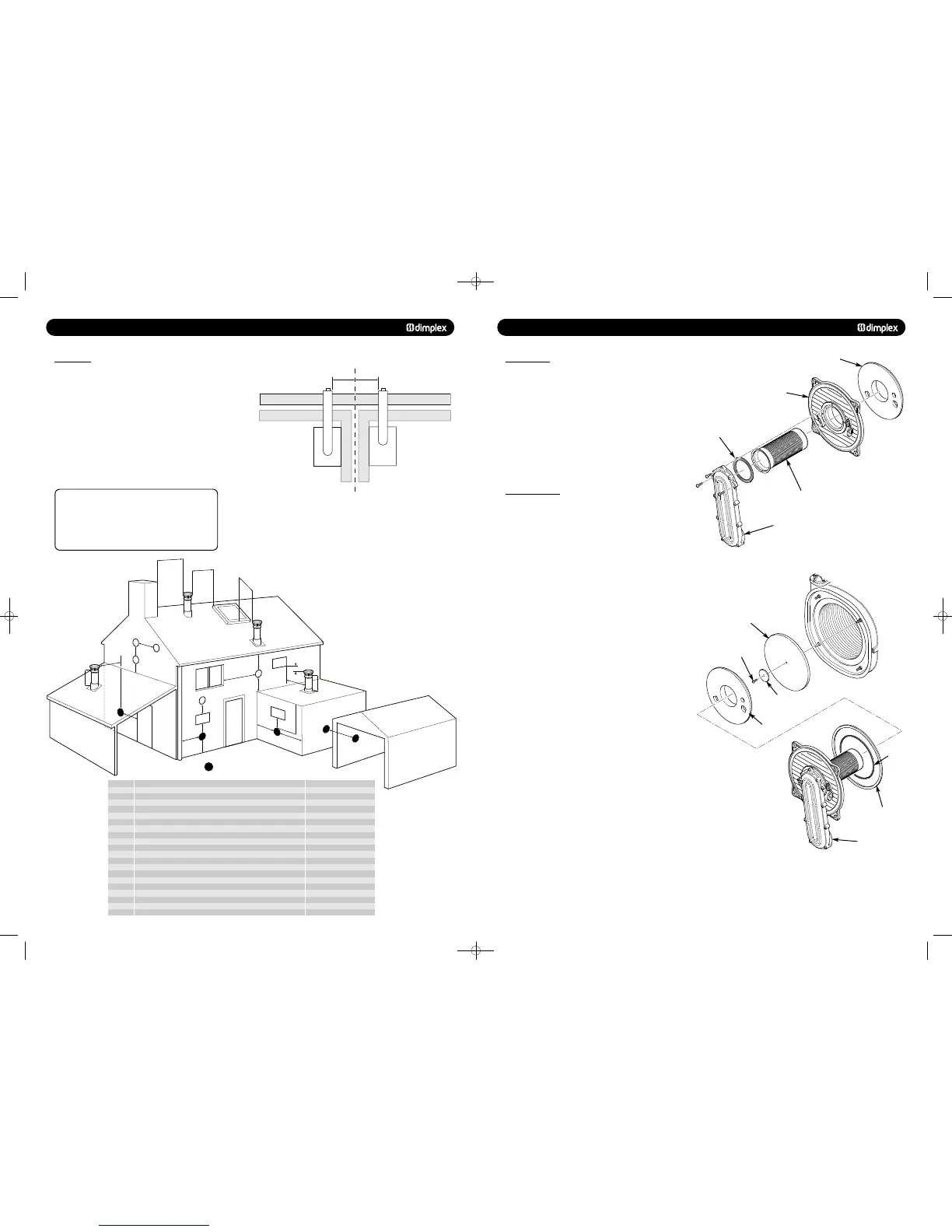

7.0 SITE REQUIREMENTS

7.7 FLUE

1. This high efficiency boiler will discharge a plume of water

vapour from the flue. This should be considered when siting

the flue terminal.

2. The following guidelines indicate the general requirements

for siting balanced flue terminals. For GB recommendations are

given in BS 5440 Pt 1. For IE recommendations are given in

the current edition of I.S. 813 “Domestic Gas Installations”.

3. If the terminal discharges onto a pathway or passageway,

check that combustion products will not cause a nuisance and

that the terminal will not obstruct the passageway.

4. If a terminal is less than 2 metres above a balcony,above

ground or above a flat roof to which people have access, then

a suitable terminal guard must be provided - Part No: 951507.

of the 25mm clearances (Positions ‘O’ to ‘S’ in

the chart below) is allowable per installation.

• Under car ports we recommend the use of the plume

displacement kit.

• The terminal position must ensure the safe and nuisance

- free dispersal of combustion products.

NOTE: The minimum distance from a flue terminal to a boundary line is 300mm.

If fitting a plume div

erter kit, the air inlet should be a minimum of 100mm from

any opening windows or doors.

NOTE A: A term

inal should

be no closer than 150mm

to an opening in the

brickwork intended to

accommodate a fitt

ing

such as a window frame.

NOTE: Fitting of the deflector

elbow is recommended when

installing boil

er to minimum

clearance of 25mm as

detailed in positions O & P.

A

M,L

M,L

N

C

F

P

O

O

R

N

S

C

C

N

Flue terminals that require a guard fitting

P

B

J

H

N

N

G

Q

K

D

E

Position Description Minimum Distance (mm)

A Horizontally to an opening, air brick, opening window - see note A 300

B Above an opening, air brick, opening window etc. - see note A 300

C Below an opening, air brick, opening window etc. - see note A 300

D Below windows or openings on pitched roofs 2000

E Adjacent to windows or openings on pitched and flat roofs 600

F From an adjacent opening window (vertical only) 1000

G From an adjacent wall to flue (vertical only) 300

H Horizontally from a terminal on the same wall 300

J Vertically from a terminal on the same wall 1500

K From an opening in a carport (e.g. door, window) into the dwelling 1200

L From a terminal facing a terminal (horizontal flue) 1200

From a terminal facing a terminal (vertical flue) 600

M From a surface or boundary line facing a terminal 600

N Above ground, roof or balcony level 300

O From an internal or external corner 25

P From a vertical drain pipe or soil pipe 25

Q Below balconies or car port roof 25

R Below eaves 25

S Below gutters, soil pipes or drain pipes 25

300mm Min 300mm Min

Adjoining Properties Boundary Line

TERMINAL POSITION

Fig. 18

Fig. 19

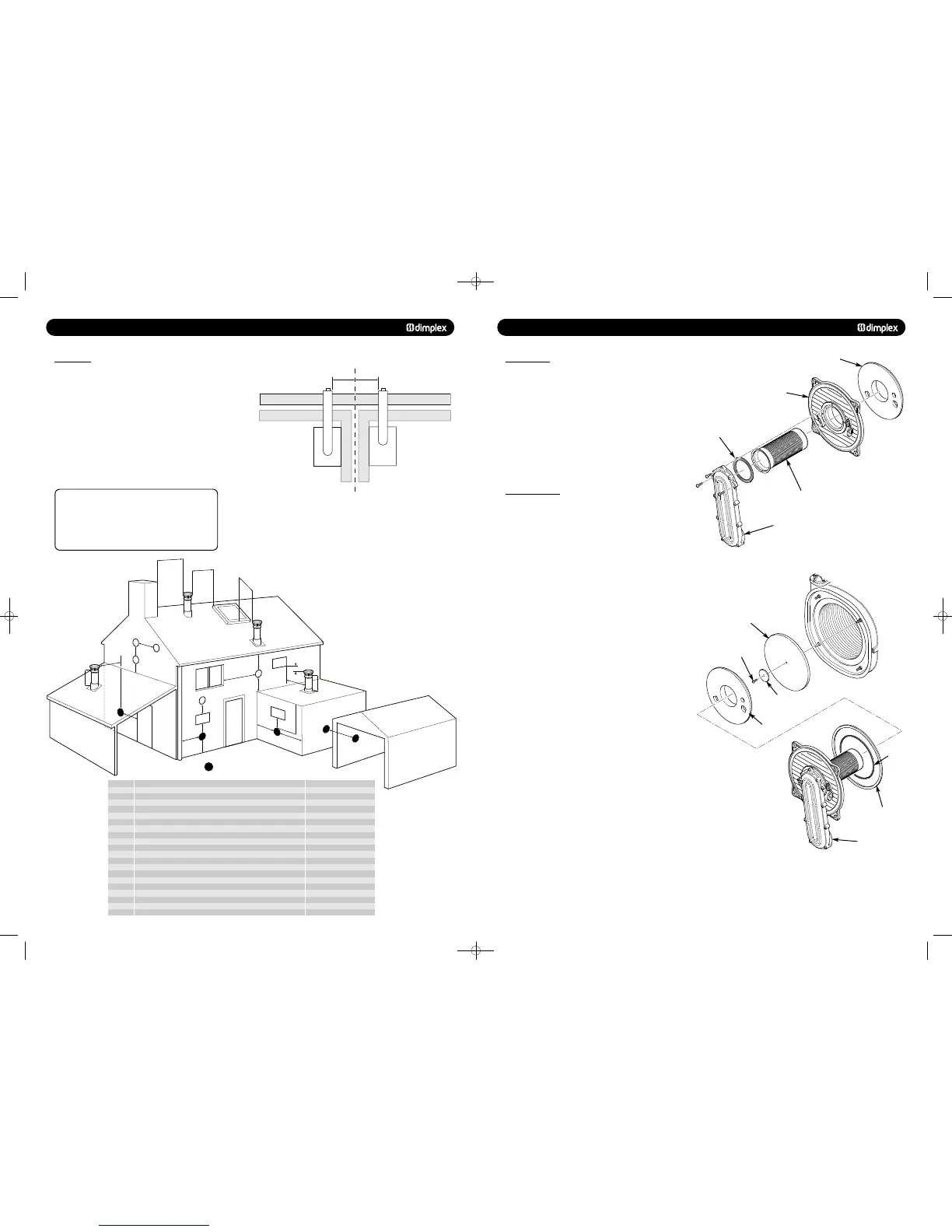

13.0 CHANGING COMPONENTS

13.4 BURNER

1. Remove the valve and fan assembly as described in Section

13.3.

2. Examine the gasket and replace if necessary.

3. Undo the four nuts securing the burner door and remove

from the heat exchanger.

4. Slowly withdraw the burner from the burner plate taking

care not to damage the insulation (Fig. 58).

5. Reassemble in reverse order.

© Dimplex Boilers 2008

1. Remove the electrode leads, noting their positions. Remove

the electrodes as described in section 13.2.

2. Remove the valve and fan assembly as described in Section

13.3.

3. Examine the gasket and replace if necessary.

4. Undo the four nuts securing the burner door and remove

from the heat exchanger.

5. Slowly withdraw the burner from the burner door.

6. Replace the insulation if necessary.

7. Check the burner door seals.

8. The rear insulation is retained by a screw and large washer,

remove these and draw the insulation out of the heat

exchanger (Fig. 59).

9. Reassemble in reverse order.

Burner

Insulation

Gasket

Air/Gas Channel

Rear Insulation

Washer

Insulation

Retaining Screw

Burner Assembly

Burner Door

Burner Door Seal

Inner Seal

751262 MANUAL 19/10/10 08:41 Page 16

Loading...

Loading...