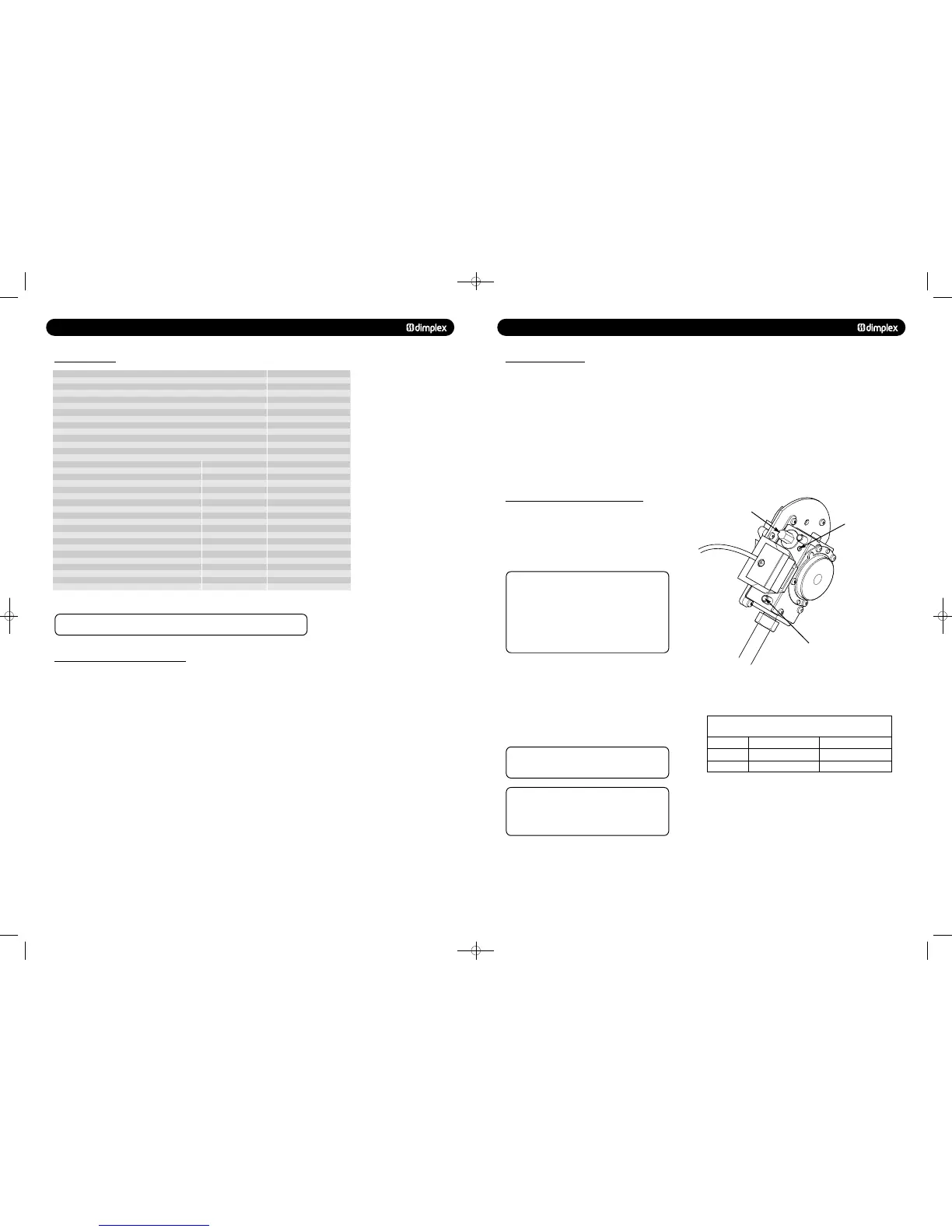

8.0 FLUE OPTIONS

8.10 FLUE LENGTHS

Length supplied in standard kit - horizontal 815mm

Max horizontal length (from boiler to chimney - 60/100mm) 2000mm

Min horizontal length (from boiler to chimney - 60/100mm) 100mm

Max vertical length (from boiler to chimney - 60/100mm) 2000mm

Min vertical length (from boiler to chimney - 60/100mm) 200mm

Length supplied in standard kit - vertical (available in 10m, 20m an 30m length) N/A

Flexitube must be purchased as an accessory to complete the kit (see below)

Flexitube min length 5m

Flexitube max length 30m

Description Part No. Equivalent Length

Horizontal - 60/100 Accessories

Flue extension duct - 500mm 956092 450mm

Flue extension duct - 1000mm (incl. 1 x support bracket) 956093 950mm

93° extension elbow 956091 1550mm

45° extension elbow (pair) 956090 775mm

Air inlet duct - included in kit N/A N/A

Straight adaptor (60/80) - included in kit N/A N/A

91.5° adaptor elbow (80/80) - included in kit N/A N/A

Support bracket - 100mm 840517 N/A

93° flanged elbow - included in kit 956082 N/A

Vertical turret socket 956087 N/A

Flexi tube - 10m 956110 10m

Flexi tube - 20m 956111 20m

Flexi tube - 30m 956112 30m

Straight duct (80) - included in kit N/A N/A

Chimney terminal - included in kit N/A N/A

Note: Equivalent length information only required for coaxial flue parts.

The corrugated (Flexi tu

be) flue parts are fixed and all parts are required for every application.

20

8.11 Additional Concentric Flue Kit Accessories

The following additional concentric kit accessories are available

as optional extras.

Flue Extension Ducts - 1000 mm (956093) and 500 mm

(956092), (each duct extends the flue length by up to 950

mm and 450 mm respectively).

93° Extension Elbow (956091) - Allows an additional bend in

the flue, and has an ‘equivalent length’ of 1550 mm. This

elbow is mechanically different from the flanged elbow

supplied as standard with the appliance, but has the same

equivalent length.

45° Extension Elbow (956090) - Allows an additional bend in

the flue and has an ‘equivalent length’ of 775 mm.

Vertical Turret Socket (956087) - For use with elevated

horizontal flues and vertical terminals.

Vertical Roof Terminal - For use where an external wall is not

available, or where it is desirable to route the ducts vertically.

For installation details refer to the instructions provided with

the individual flue kits.

These optional kits may be used with the standard flue kits to

produce an extensive range of flue options, providing that the

following rules are strictly obeyed.

a) The maximum/minimum permissible length of the room

sealed flue system are:

Horizontal flue terminal (all orientations)

maximum 10000 mm

Horizontal flue terminal (rear exit)

minimum 250 mm

Vertical flue terminal maximum 12000 mm

Vertical flue terminal minimum 600 mm

The ‘equivalent’ flue length must not exceed the maximum

values stated.

b) The standard terminal must be fitted horizontally; horizontal

ducts must have a continuous fall towards the appliance of

1.5° to 3°. This ensures condensate runs back into the

appliance from the flue system. The vertical terminal must

always be used if a vertical outlet is required.

c) The concentric flue system must use either a flanged elbow

or a vertical flue turret socket at the entry/exit to the

appliance.

d) All joints must be correctly made and secured in accordance

with the installation instructions. When cutting ducts, avoid

swarf, uneven and sharp edges to maintain duct integrity.

Refer to Fig. 19 & 20 to determine which option kits are

required before commencing the installation. Instructions for

installing the appliance with a horizontal flue and straight

extension ducts are included in the main text of these

instructions (section 9.5).

12.0 SERVICING AND MAINTENANCE

12.2 COMBUSTION CHECKS

COMBUSTION CHECKS AT MAXIMUM RATE

9. Set the boiler to Maximum gas rate.

10. Check the Carbon Monoxide (CO) and Carbon Dioxide (CO

2

)

readings are within the range quoted in the tables opposite

(Table 2).

11. If the combustion value(s) is outside the values specified

in Tables 1 and 2 and the integrity of the full flue system and

combustion circuit seals, the inlet gas pressure and gas rate

have been verified, it is possible to make an adjustment to the

combustion settings by adjustment of the air/gas ratio valve.

See Section 12.3 Adjustment of the Gas Valve.

© Dimplex Boilers 2008

29

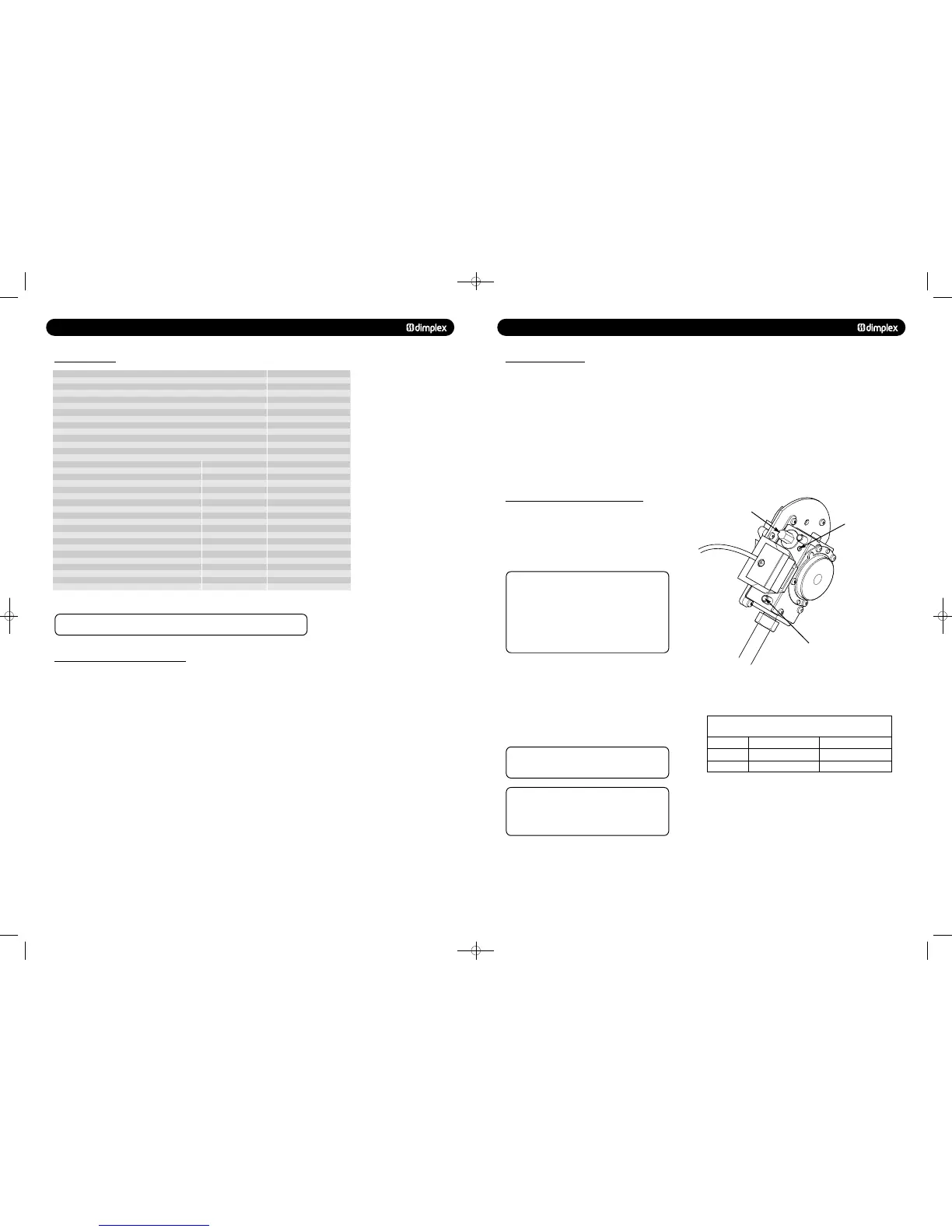

12.3 ADJUSTMENT OF THE GAS/AIR RATIO VALVE

COMBUSTION SETTING ADJUSTMENT

1. It is only possible to adjust the valve at Maximum rate. No

adjustment at Minimum rate is allowed.

2. If the maximum rate setting is adjusted, then the

combustion values must be checked at minimum rate.

DO NOT ATTEMPT TO ADJUST THE GAS/AIR RATIO

VALVE UN LE S S ;

• The person carrying out the measurement has been

assessed as competent in the use of a flue gas analyser

and the interpretation of the results.

• The flue gas analyser used, meets the requirements of

BS7927 or BS-EN50379-3.

• The flue gas analyser is calibrated in accordance with the

manufacturers requirements.

3. At Maximum Gas Rate; put the appliance into Service Mode

at Maximum Gas Rate (see Section 11.2).

4. Wait 5 minutes to allow the boiler to stabilise.

5. If the Carbon Dioxide (CO

2

) level is outside the required

values given in Section 12.2 (Table 2) then adjust the throttle

screw (Fig. 48) until the CO

2

is at the correct setting level. See

Table 4. Clockwise to decrease CO

2

, anti-clockwise to increase

CO

2

.

Only turn the throttle in small steps of

no more than

1/8

th

of a turn

and wait 1 minute after each adjustment for

the combustion reading to stabilise.

After any adjustment of the gas valve, it is

essential to check the combustion levels at minimum gas

rate (Table 1). If the Carbon Monoxide or Carbon Dioxide

levels are outside the range quoted, call Dimplex Boilers Ltd

Technical Helpline on 0844 3711121. If in doubt ASK!

Factory set - warranty

void if adjusted

Throttle Adjuster Screw

Carbon Dioxide (CO2) acceptable setting level at Maximum

Gas Rate after 5 minutes operation

Natura

l Gas %Boiler Model

System 18

751262 MANUAL 19/10/10 08:41 Page 20

Loading...

Loading...