•Page globalcontract.com 8

• Summer 2017

GLOBALContract

INSTALLATION GUIDELINES

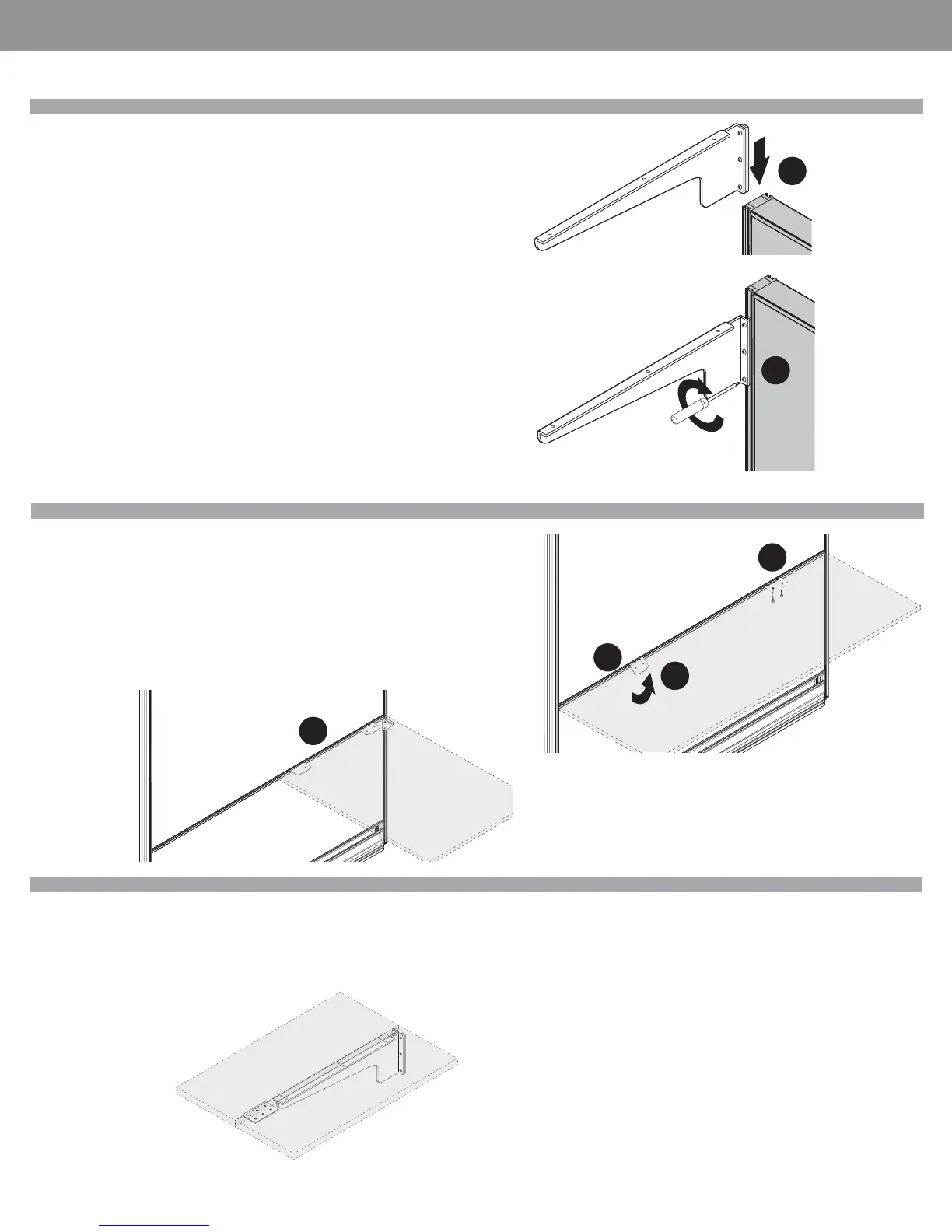

Cantilevers / Corner Brackets

Installation Tip:

• Build from the BOTTOM....UP!

• Slide all Worksurface Supports and Brackets into place...FIRST. Tackboards/Write-

boards /Load Bars, SECOND. Overhead Storage / Shelves, THIRD.

STEP 1: Slide worksurface supports, with connection plate and screws attached,

into groove on side of panel.

STEP 2: Make sure that the screws are fl ush, and do not protrude through the

connection plate.

STEP 3: Securely attach all screws using a #4 ALLEN BIT, or TORX T25 HEAD BIT.

Gauges are provided with every cantilever and corner bracket.

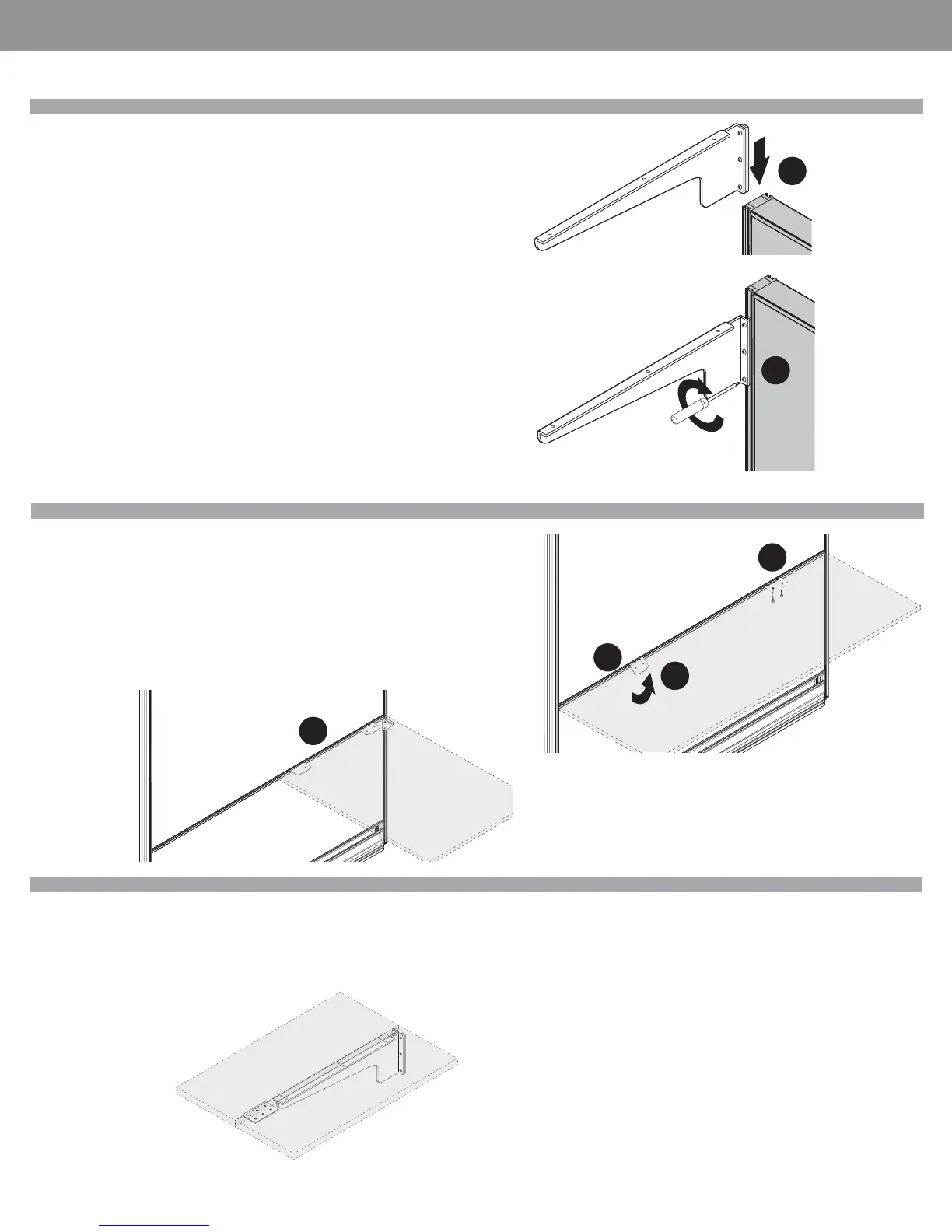

Mid Span Support Brackets (Can ONLY be used with Segmented Panels)

STEP 1: Insert bottom portion of Mid Span Support bracket into segmentation

channel, below worksurface height.

STEP 2: Lift bracket to secure it into segmentation channel.

STEP 3: Secure bracket to worksurface using short wood screws.

STEP 4: Mid Span Support Brackets can be used as additional support for longer

worksurfaces or to create an off-module connection, as shown.

Adjacent Worksurface Mounting

Two Cantilevers, leveled side-by-side with Flat Plate to align front edges of

worksurfaces.

One Corner Bracket, plus (2) Mid-Span Support Brackets (using Segmented

Panels ONLY) to create an off-module worksurface connection.

1

3

1

2

3

4

Loading...

Loading...