Supplied By www.heating spares.co Tel. 0161 620 6677

13

4.4 Bypass

The boiler is fitted with an adjustable automatic bypass.

Diagram 4.2 shows the pump head remaining for the heating

system depending on the bypass setting and the speed

setting of the pump, see section 11 Commissioning.

Ensure that under no circumstances does the flow rate drop

below the figure specified, refer to table 3 and section 11.6.

The installation of the boiler must comply with the

requirements of the current issue of BS6798, in Ireland,

refer also to the current edition of I.S.813 “Domestic Gas

Installations”.

In GB it is necessary to comply with the Water Supply (Water

Fittings) Regulations 1999 (for Scotland, the Water Byelaws

2000, Scotland).

To comply with the Water regulations your attention is drawn

to: The Water Regulations guide published by the Water

Regulations Advisory Service (WRAS) gives full details of the

requirements.

In IE the requirements given in the current edition of I.S.813

“Domestic Gas Installations” and the current Building

Regulations must be followed.

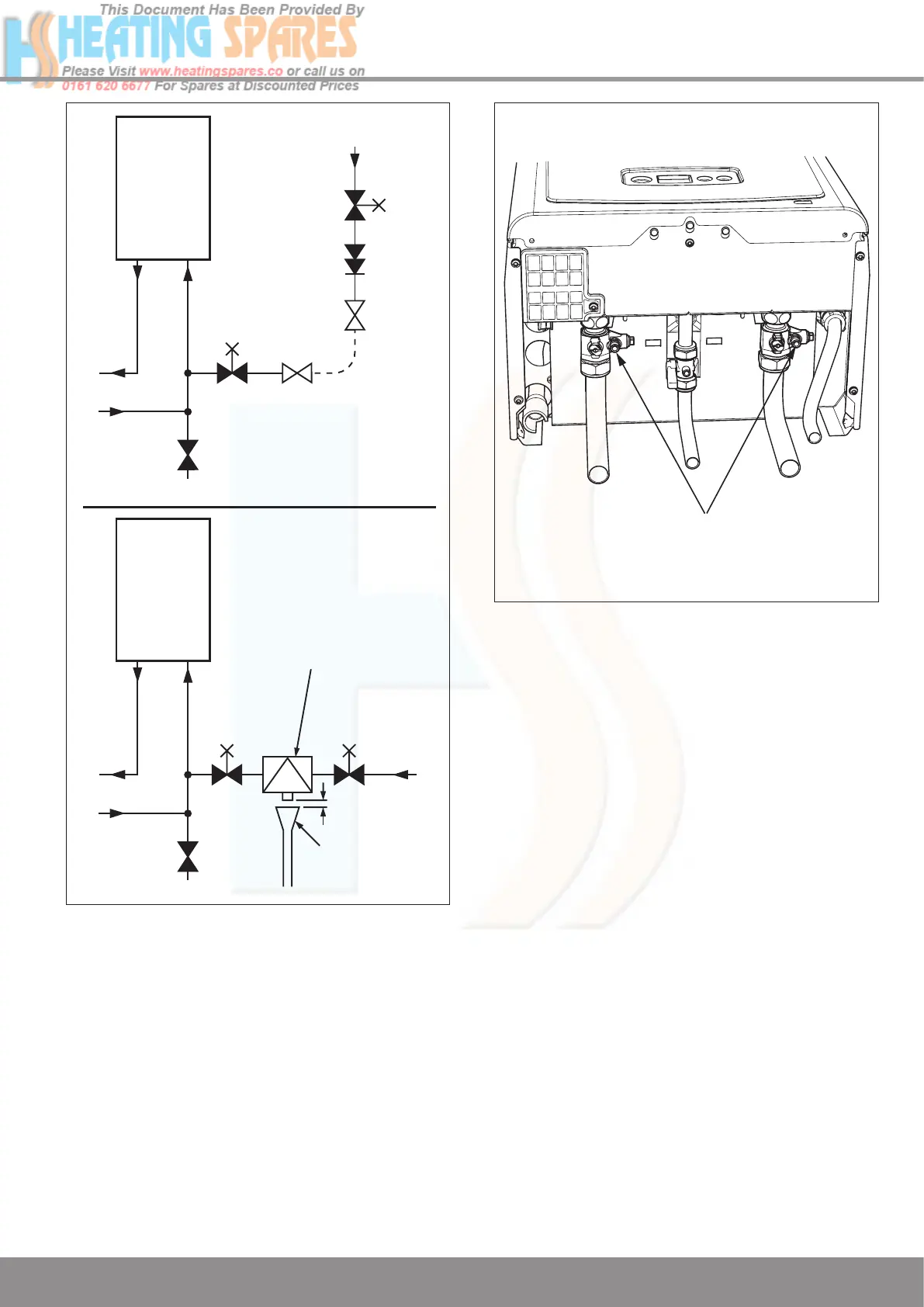

4.5 Filling the Sealed System

Provision for filling the system at low level must be made, see

diagram 4.3. There must be no permanent connection to the

mains water supply, even through a non-return valve.

NOTE: It is important that fittings used for connection

to potable water comply with the water undertakings

requirements.

4.6 Water Treatment

In the case of an existing system, it is ESSENTIAL that prior

to installing the new boiler the system is thoroughly flushed.

For optimum performance after installation of a new system,

the boiler and its associated central heating system should

also be flushed. Flushing should be carried out in accordance

with BS7593: 1992 using a cleanser such as Sentinel X300

or X400, Fernox Restorer or Salamander corrosion guard

cleaner.

For long-term corrosion protection, after flushing, a suitable

inhibitor should be used, refer to the current issue of BS

5449 and BS 7593 on the use of inhibitors in central heating

systems. Examples are Sentinel X100 Fernox Protector or

Salamander corrosion guard inhibitor.

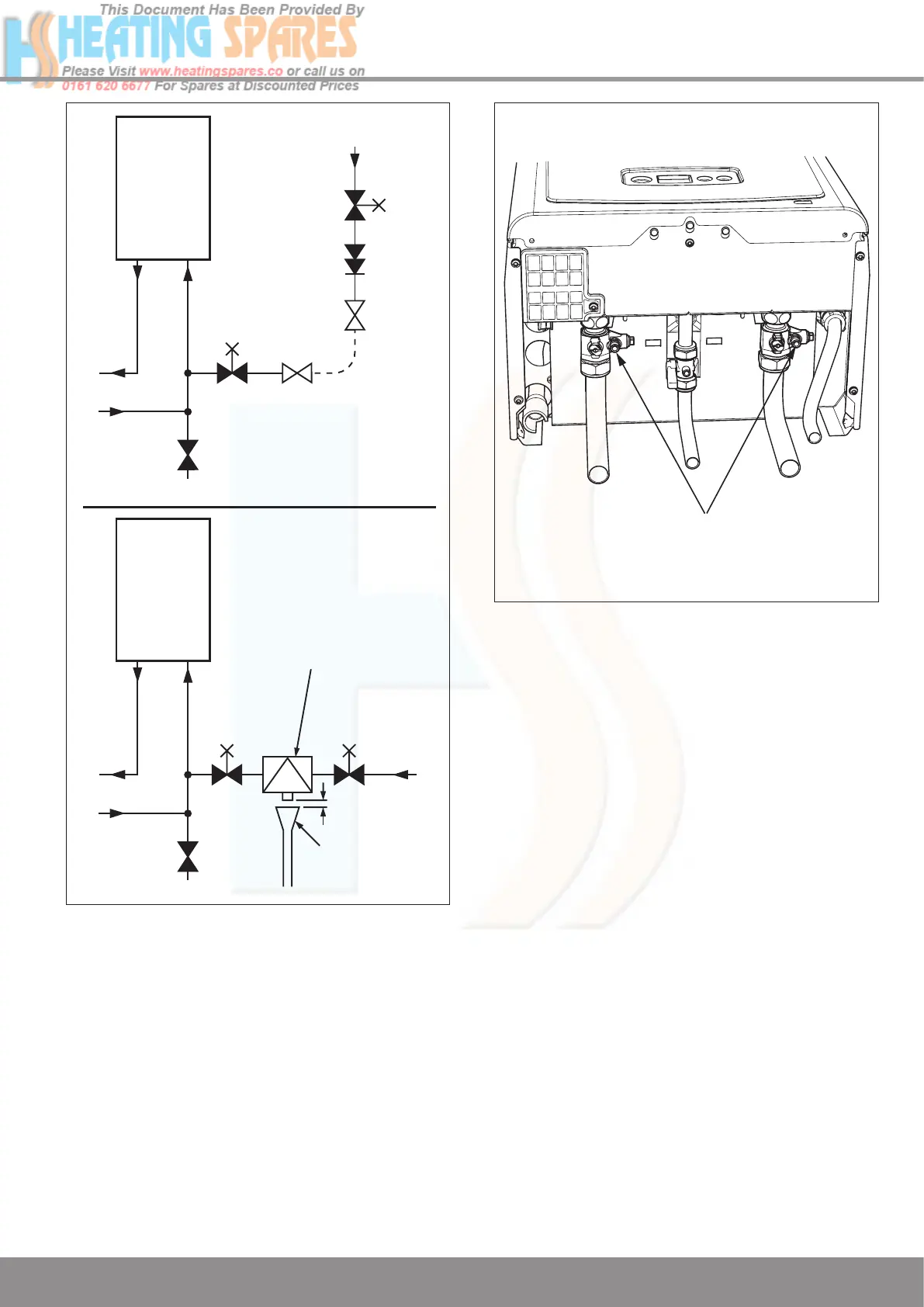

4.7 Draining Points

Draining taps must be provided at the lowest points of the

system, which will allow the entire system to be drained.

Drain points for the appliance are provided at the positions

shown in diagram 4.4.

Diagram 4.4

13034

4 Heating System

TEMPORARY

CONNECTION

HOSE

UNION

HOSE

UNION

SUPPLY

PIPE

CONTROL

VALVE

CONTROL

VALVE

DOUBLE

CHECK

VALVE

BOILER

RETURNFLOW

HEATING

CIRCUIT

DRAIN

POINT

SUPPLY

PIPE

AIR GAP

TUNDISH

CONTROL

VALVE

CONTROL

VALVE

TYPE CA BACKFLOW

PREVENTION DEVICE

BOILER

RETURNFLOW

HEATING

CIRCUIT

DRAIN

POINT

Method 1

Method 2

Diagram 4.3

11593

Loading...

Loading...