Supplied By www.heating spares.co Tel. 0161 620 6677

9 Flue Preparation and Installation

Horizontal Terminal Installation

With due consideration to terminal clearances mentioned in

Section 3.2 drill the one or two holes as required with a 90mm

core drill.

Push the horizontal terminal through the wall allowing approx.

100mm to protrude outside.

Push a grey rubber wall seal

onto either side of the wall ensur-

ing that both wall seals are pushed up to the wall surface, see

examples (b) and (c) diagram 9.25.

Vertical Terminal Installation

With due consideration to terminal clearances mentioned in

Section 3.2, project the rise of the flue pipe to roof level and

cut 150mm hole in the roof.

(a) Pitched Roof

Fit the required pitched roof weather collar over the 150mm

hole in the roof. Make good the tiling or slating around the

collar incorporating the flashing of the weather collar. Position

the angle cap over the weather collar in the correct orientation

to attain the correct angle for your roof. One way round gives

a pitch of 25°-38° and the other gives 37°- 50°.

(b) Flat Roof

Fit the aluminium weather collar over the 150mm hole in the

roof ensuring a weather tight seal.

Horizontal Pipes-Completion of Installation

Having built the pipe(s) from the boiler to the terminal(s), the

length of the final pipe piece can be determined. Cut pipes at

the opposite end to the ‘O’ ring seal making square and free

from burrs. Push the horizontal terminal through the wall to

engage the final pipe piece and pull back ensuring the grey

wall seals are fully pulled up to the outside and inside wall

faces.

Vertical Pipes-Completion of Installation

Refer to diagram 9.25.

For installation of (a), attach the twin pipe to concentric flue

adaptor, part number A2011600, to the base of vertical ter-

minal assembly. For installation of (b), attach the single pipe

to concentric adaptor, part number A2011500, to the base of

vertical terminal assembly.

With the vertical terminal assembly positioned in the roof,

the length of the final pipe can be determined. Cut the fl

ue

to the desired length measuring from the ‘O’ ring seal end

and discard the plain end of the tube. The cut end should be

square and free from burrs. Carefully push the terminal as-

sembly upwards to allow room for fitting the final flue piece(s).

Fit a 100mm fixing bracket to the terminal assembly Part

No2000460486. Pull the terminal assembly down and join to

the flue system. Ensure that the terminal is making a weather

tight seal on the weather collar

. Secure the fixing bracket fitted

to the terminal to the roofing struts or a purpose made batton.

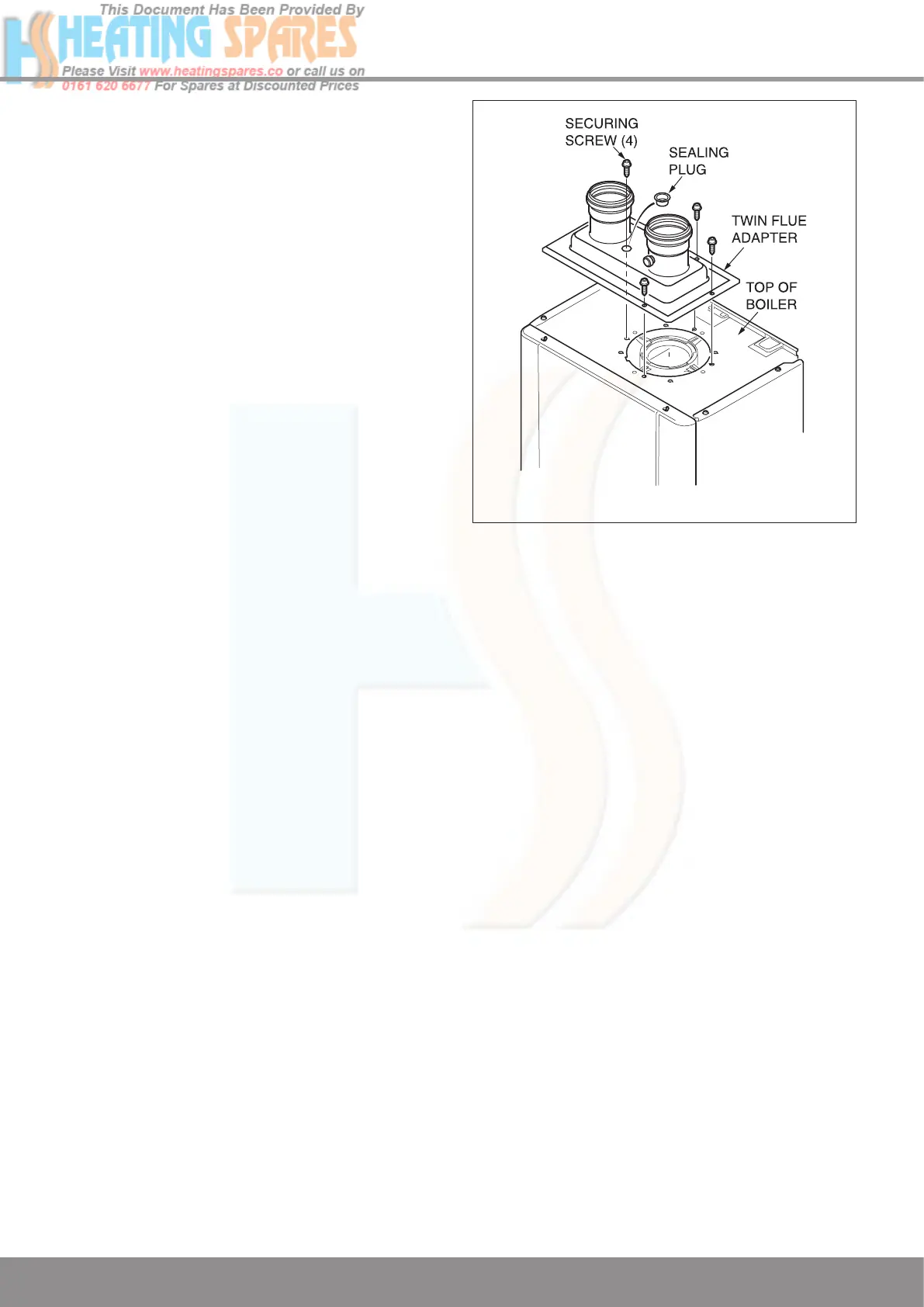

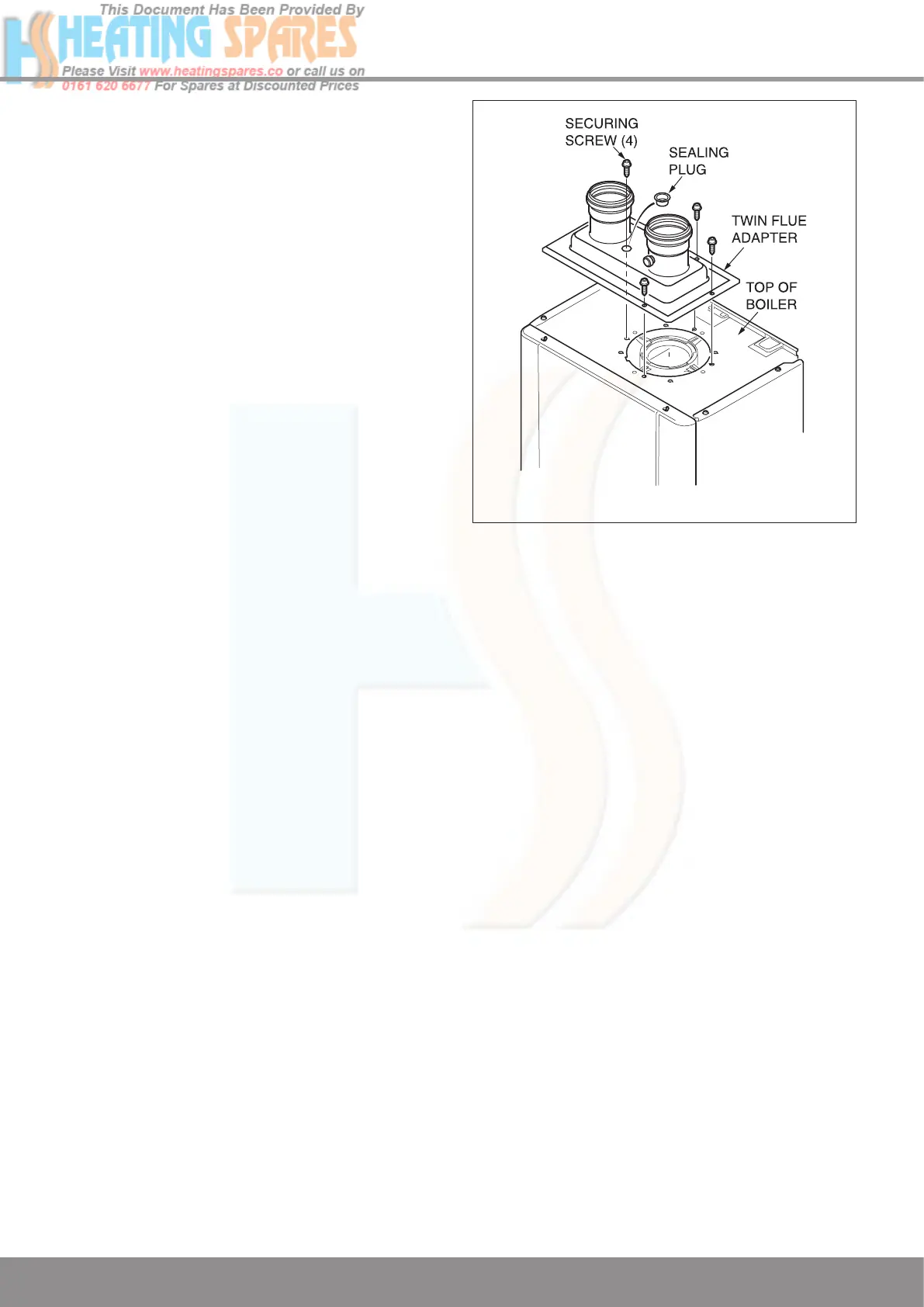

Diagram 9.24

12985

Loading...

Loading...