8

7.3 Special Instructions

Units without a factory installed TXV come equipped with a flowrator piston for refrigerant expansion. For most instal-

lations with matching applications, no change to the flowrator piston is required. However, in mix-matched applica-

tions, a flowrator piston change may be required. See the piston kit chart (provided in the literature packet) or consult

your local distributor for details regarding mix-matched flowrator piston sizing. If the mix-match application requires a

different flowrator piston size, change the flowrator piston in the flowrator body on the indoor coil before installing the

coil and use the procedure in section 8.4.

NOTE: The use of a heat shield is strongly recommended when brazing to avoid burning the serial plate or the finish

of the unit. Heat trap or wet rags must be used to protect heat sensitive components such as service valves and TXV

valves sensing bulb.

7.4 Tubing Connections for Flowrator Model

1. Loosen the 13/16 nut 1 TURN ONLY to allow high pressure tracer

gas to escape. No gas indicates a possible leak.

2. After the gas has been expelled, remove the nut and discard the

black or brass cap plastic seal.

3. Remove the flowrator piston to verify it is the correct size for the

outdoor unit being installed and then replace the piston (changing

size, if needed). See piston kit chart in the literature kit for appropri-

ate piston size.

4. Remove the spin closure on the suction line using a tube cutter and

deburr the tube.

5. Insert the suction line into the connection, slide the insulation and

the rubber grommet at least 18" away from the braze joint.

6. Remove the tailpiece clamped to the exterior of the cabinet or in

the literature kit packet and slide the 13/16 nut into place.

7. Braze tailpiece to the line set liquid tube and braze suction line

connection. Quench all brazed joints with a damp rag upon comple-

tion of brazing. Do not allow water to enter the inside of the tubing.

8. AFTER THE TAILPIECE HAS COOLED, confirm position of the

white Teflon

®

seal and hand tighten the 13/16 nut.

9. Torque the 13/16 nut to 7-25 ft-lbs. or tighten 1/6 turn.

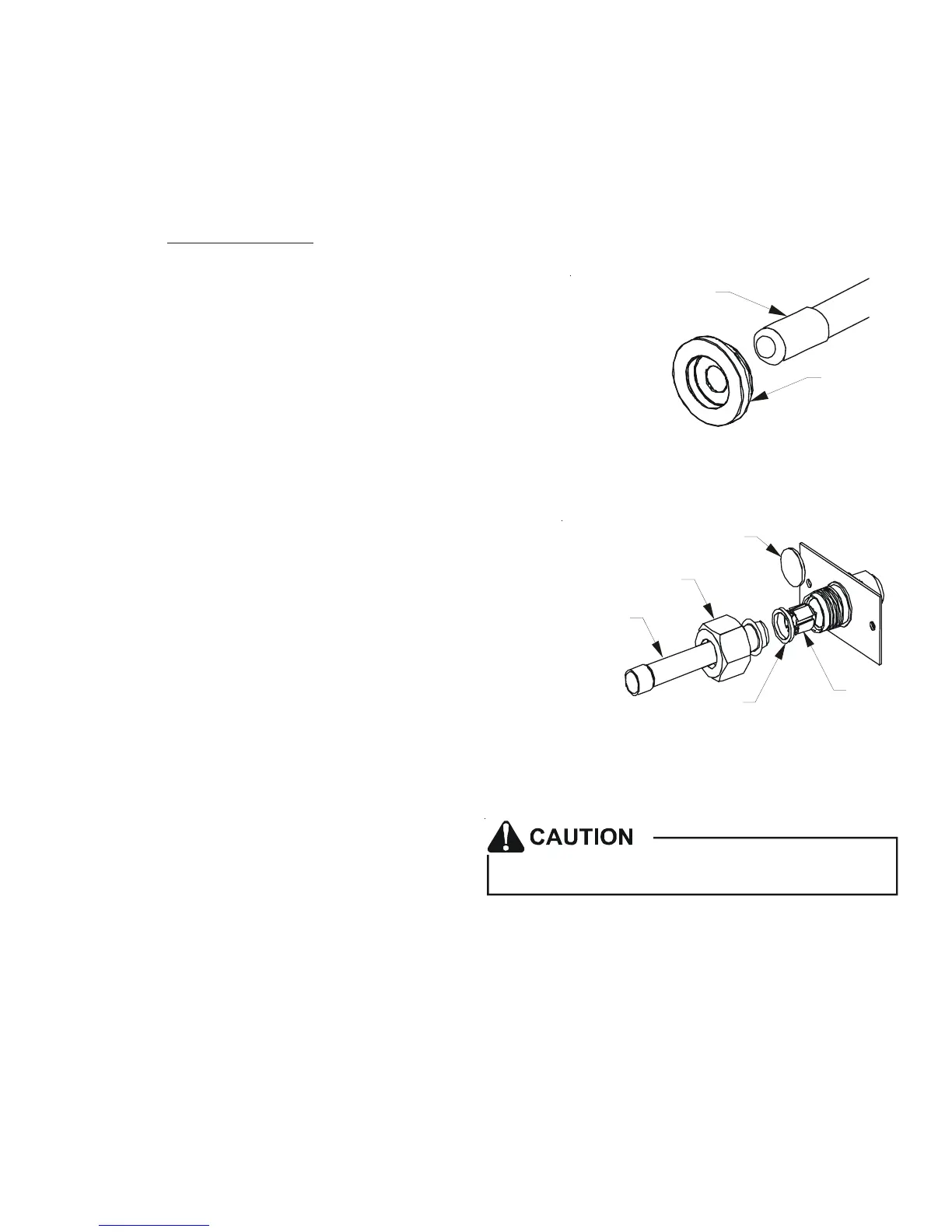

RUBBER

GROMMET

SUCTION LINE

WITH SPIN CLOSURE

SUCTION SPUN END AND GROMMET

Figure 10

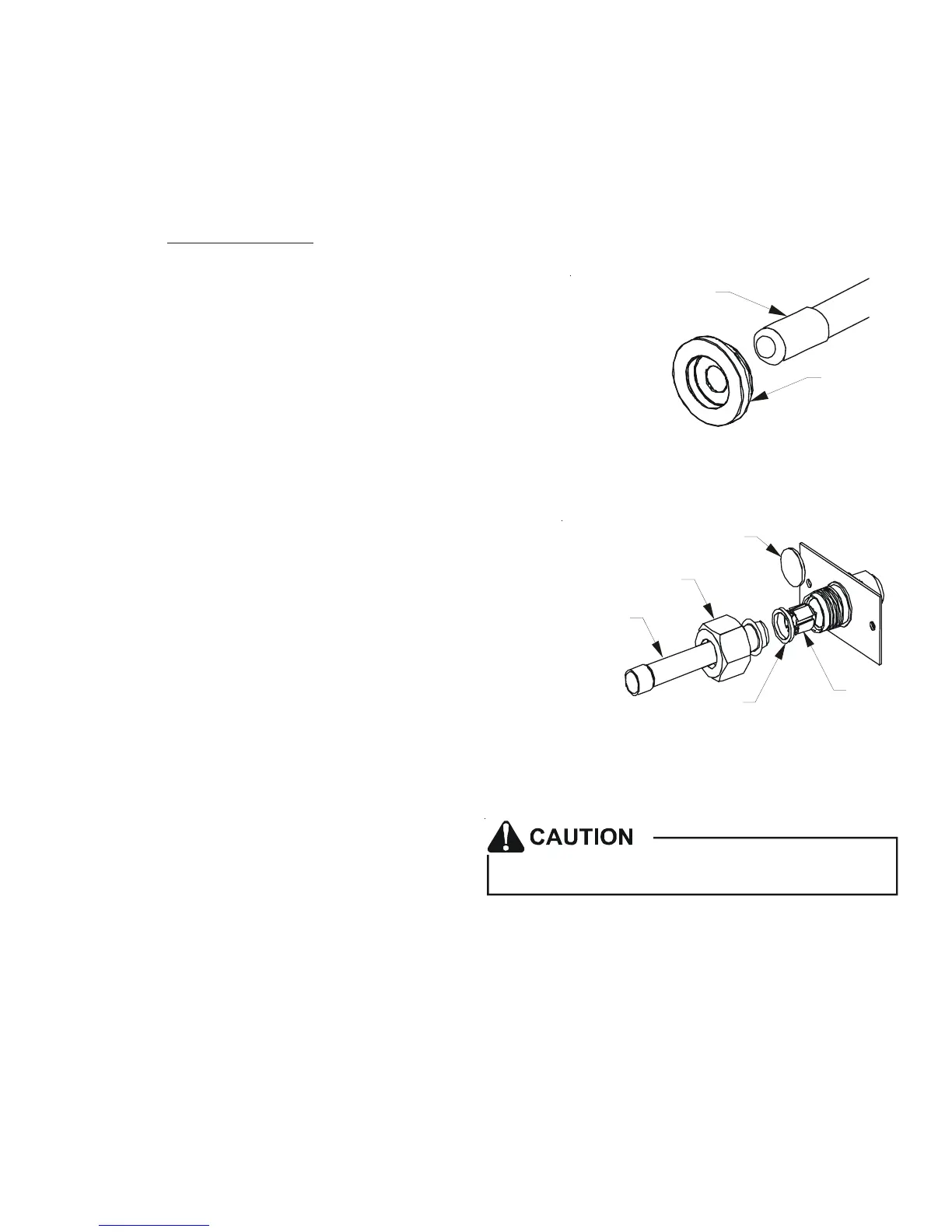

WHITE

TEFLON SEAL

PISTON

TAILPIECE

13/16” NUT

PLASTIC or BRASS CAP

TAILPIECE JOINT

Figure 11

Excessive torque can cause orifices to stick. Use the

proper torque settings when tightening orifices.

7.5 Tubing Connections for TXV Models

TXV models come with factory installed TXV with the bulb pre-installed on the vapor tube.

1. Remove refrigerant tubing panel or coil (lower) access panel.

2. Remove access valve fitting cap and depress the valve stem in access fitting to release pressure. No pressure indi-

cates possible leak.

3. Replace the refrigerant tubing panel.

4. Remove the spin closure on both the liquid and suction tubes using a tubing cutter.

5. Insert liquid line set into liquid tube expansion and slide grommet about 18" away from braze joint.

6. Insert suction line set into suction tube expansion and slide insulation and grommet about 18" away from braze joint.

7. Braze joints. Quench all brazed joints with water or a wet rag upon completion of brazing.

Loading...

Loading...