24

9. Install the bottom of the flexible coupling to the top

of the drive shaft.

10. Attach a sling to the lifting lugs of driver and hoist

the driver up. Inspect the mounting surface, register

and clean these surfaces thoroughly. If any burrs

are found, remove burrs with a smooth mill file,

cleaning thoroughly afterward. Temporarily attach

the top half of the flexible coupling to the motor

shaft.

11. Orient the motor conduit box in the required

position. Align the driver mounting holes with

the mating tapped holes on the discharge

head. Lower the driver until the registers

engage and the driver rests on the thrust

pot assembly. Secure driver with capscrews

provided.

12. Secure the flexible coupling assembly.

13. Install the coupling guard.

14. Fill the oil reservoir with recommended oil.

Pump Startup And Operation – SECTION 4

PRE-START PROCEDURE

Consult the applicable manufacturer’s instructions

for detailed information for the prime mover

(electric motor, engine or steam turbine), coupling,

driveshaft, gear driver. Prior to startup, check the

following:

1. Confirm that the following procedures

described in the “Installing the Drivers”

sections have been performed:

A. Wiring of Driver.

B. Driver must rotate counterclockwise

(CCW) when viewed from above.

Do not check motor rotation unless motor

is bolted to pump and drive coupling is

removed.

Be sure to remove all the hand tools and to install the

coupling guards around all exposed shafts and couplings

before start up of the pump. Failure to comply may

result in sever personnel injury or death.

C. Check alignment of pump and driver.

D. Impeller adjustment has been made.

E. Mechanical seal lock collar is attached to shaft.

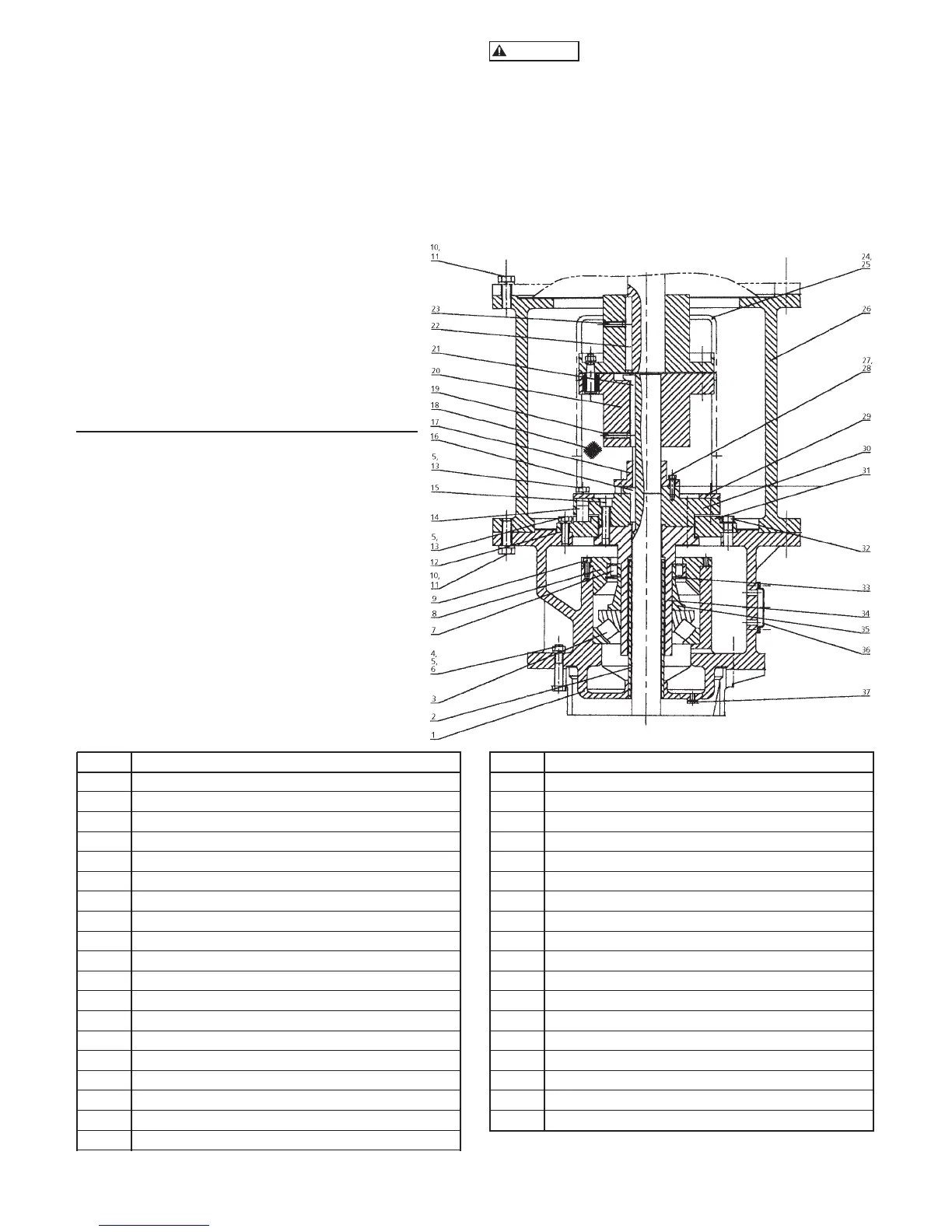

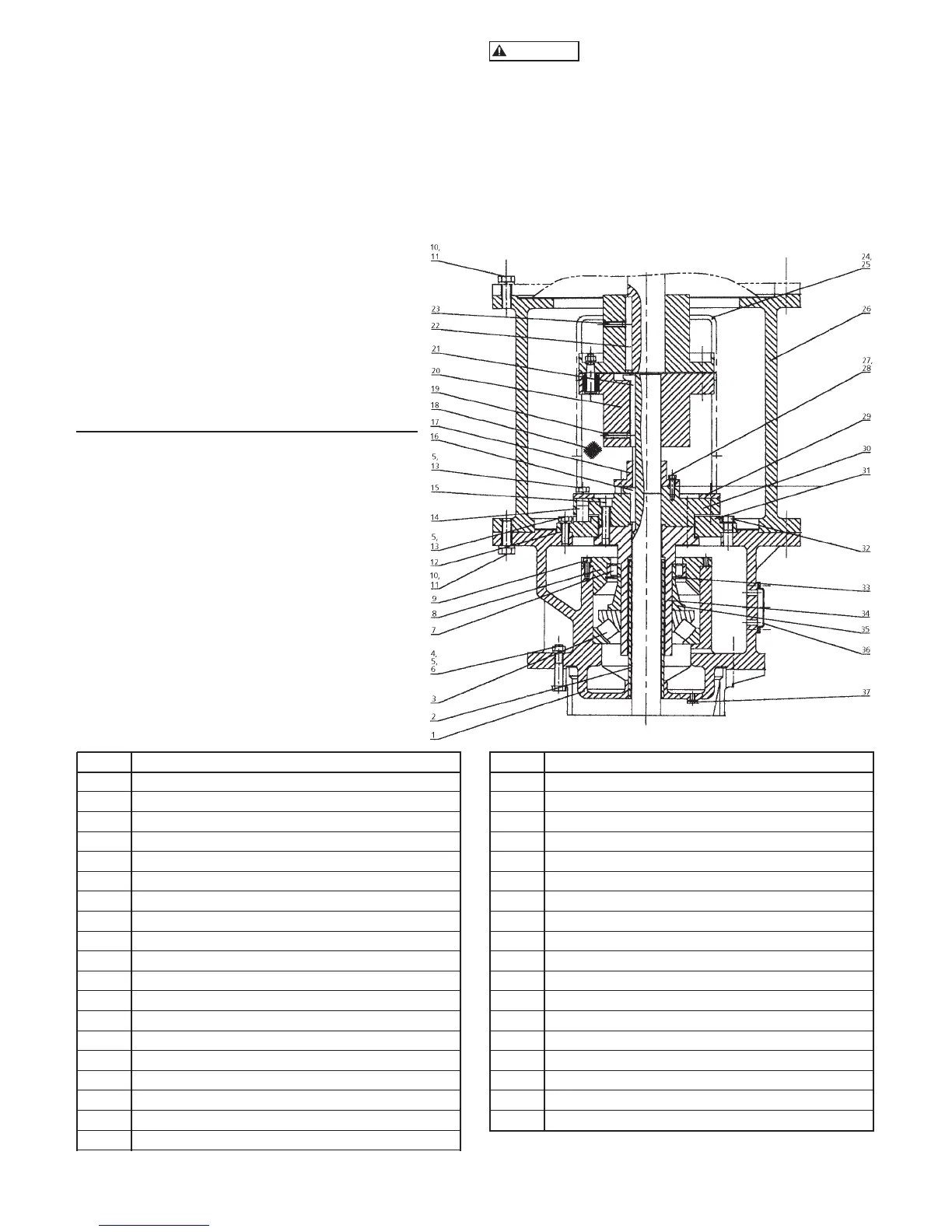

ITEM DESCRIPTION

1 Thrust pot body

2 Tube - oil retaining

3 Thrust bearing

4 Capscrew - head to thrust pot

5 Washer - head to thrust pot

6 Hex Nut - head to thrust pot

7 Roller bearing

8 Bearing seat

9 Allen head screw

10 Capscrew - motor adapter to motor or thrust pot

11 Washer - motor adapter to motor or thrust pot

12 Gasket

13 Capcsrew

14 Non-reverse pin

15 Socket head screw

16 Gib key

17 Adjusting nut

18 Coupling guard

19 Setscrew

ITEM DESCRIPTION

20 Flexible shaft coupling

21 Gib key

22 Key (motor shaft)

23 Setscrew

24 Round head screw for coupling guard

25 Washer coupling guard

26 Motor adapter

27 Capscrew - adjusting nut

28 Washer - adjusting nut

29 Retaining ring

30 Hollow shaft clutch

31 Non-reverse plate

32 Pipe plug - oil filling

33 Retaining ring

34 Hollow shaft

35 Shaft sleeve

36 Sight gauge

37 Pipe plug - oil drain

Figure 19 – Oil Lubricated Thrust Pot

Loading...

Loading...