Shutdown and Cleaning

3A2854G 15

Shutdown and Cleaning

The motor has a built-in feature to protect itself from

overuse. If the motor stops, the thermal switch has tripped.

Do not return sprayer to store. The motor will

operate normally after cooling for 20-30 minutes.

For best results, do not spray more than one cup of water

through the tip while cleaning. If more flushing

is needed, remove the tip from the sprayer.

Flushing Sprayer

1. Engage trigger lock and pull prime/spray valve UP to

release pressure.

2. Remove material cup and return excess material to

proper container. If used, properly dispose the material

cup liner.

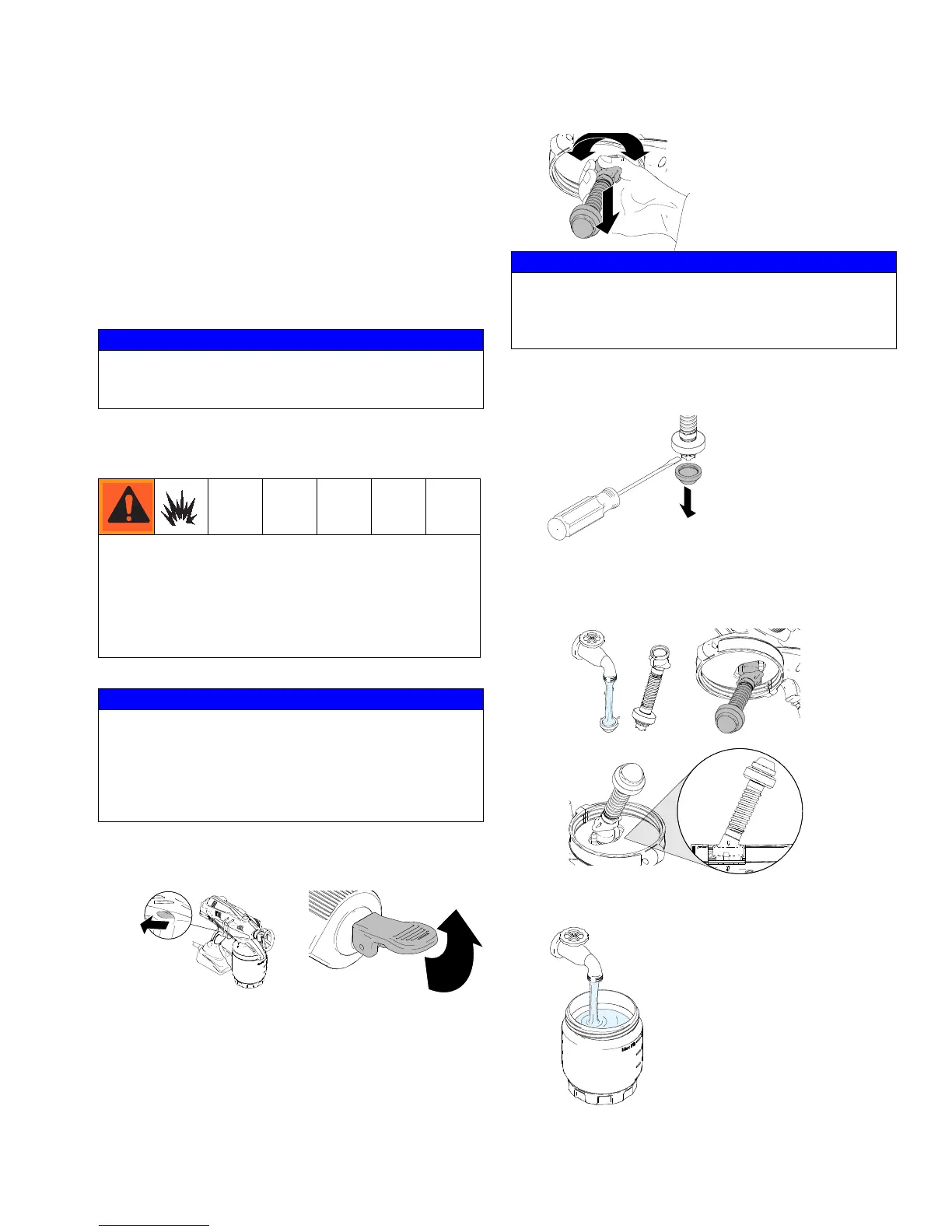

3. Remove flexible suction tube as shown below.

4. Use screwdriver to pry flexible suction tube strainer

from flexible suction tube.

5. Clean flexible suction tube and suction tube strainer

with water (or flushing fluid) and a brush every time

you flush the sprayer. Reconnect flexible suction tube

and suction tube strainer and orient as shown.

6. Clean material cup if not using a liner, and fill with

water or appropriate flushing fluid.

NOTICE

Failure to properly clean sprayer after each use will

result in hardened materials, damage to the sprayer, and

the warranty will no longer be valid.

Use only water-based materials. Do not use materials

which state “FLAMMABLE” on the packaging. For more

information about your material, request MSDS from dis-

tributor or retailer.

Keep spray area well-ventilated. Keep a good supply of

fresh air moving through the area.

NOTICE

Protect the internal parts of this sprayer from water.

Do not submerge the sprayer in cleaning fluid. Openings

in shroud allow cooling of mechanical parts and electron-

ics inside. If water or cleaning fluid gets into these open-

ings, the sprayer could malfunction or become

permanently damaged.

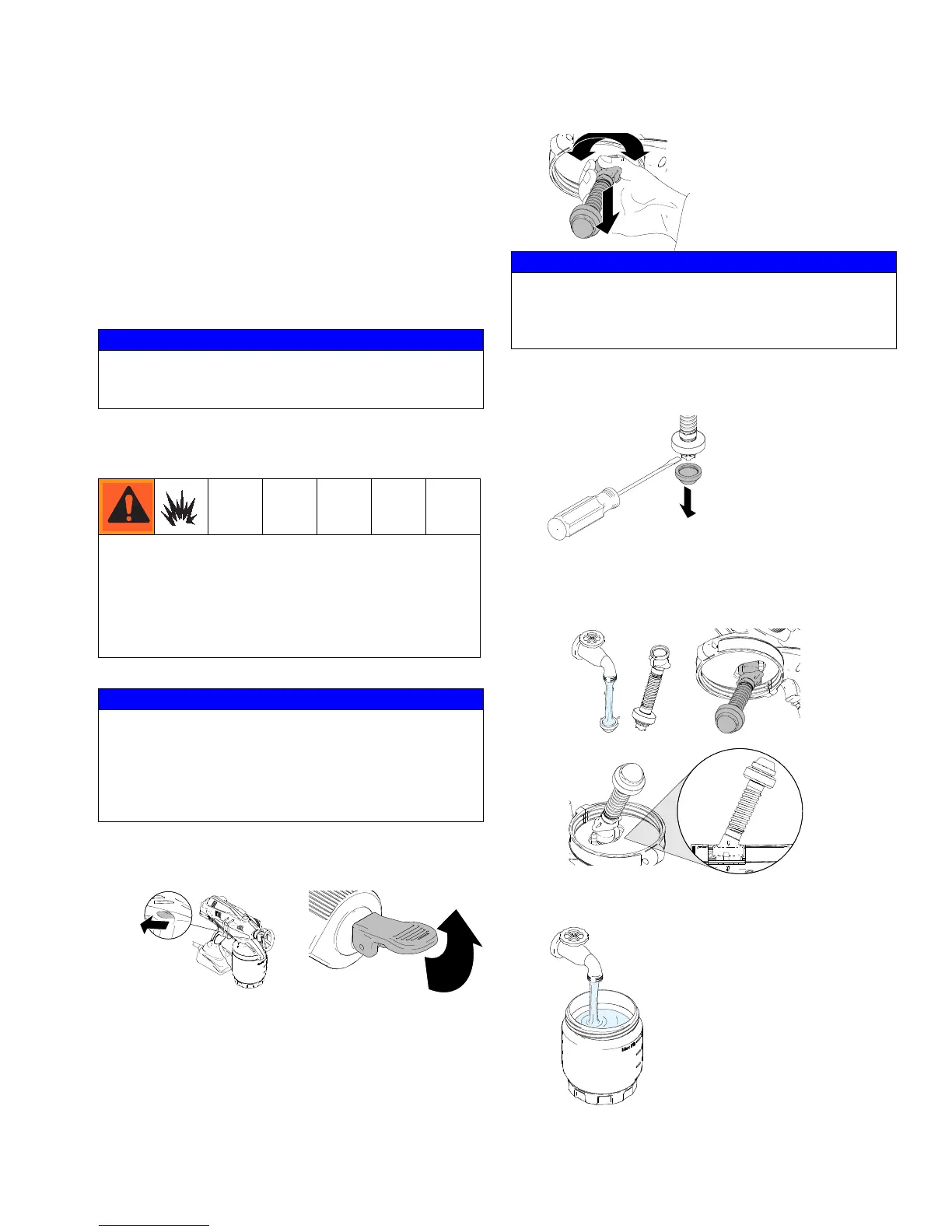

NOTICE

When removing flexible suction tube from sprayer, make

sure to pull directly on top fitting of flexible suction tube.

The tube will become damaged if pulled from bottom or

on flexible portion.

Loading...

Loading...