Troubleshooting

12 308647T

Troubleshooting

Follow the Pressure Relief Procedure, page 10,

before checking or repairing the equipment.

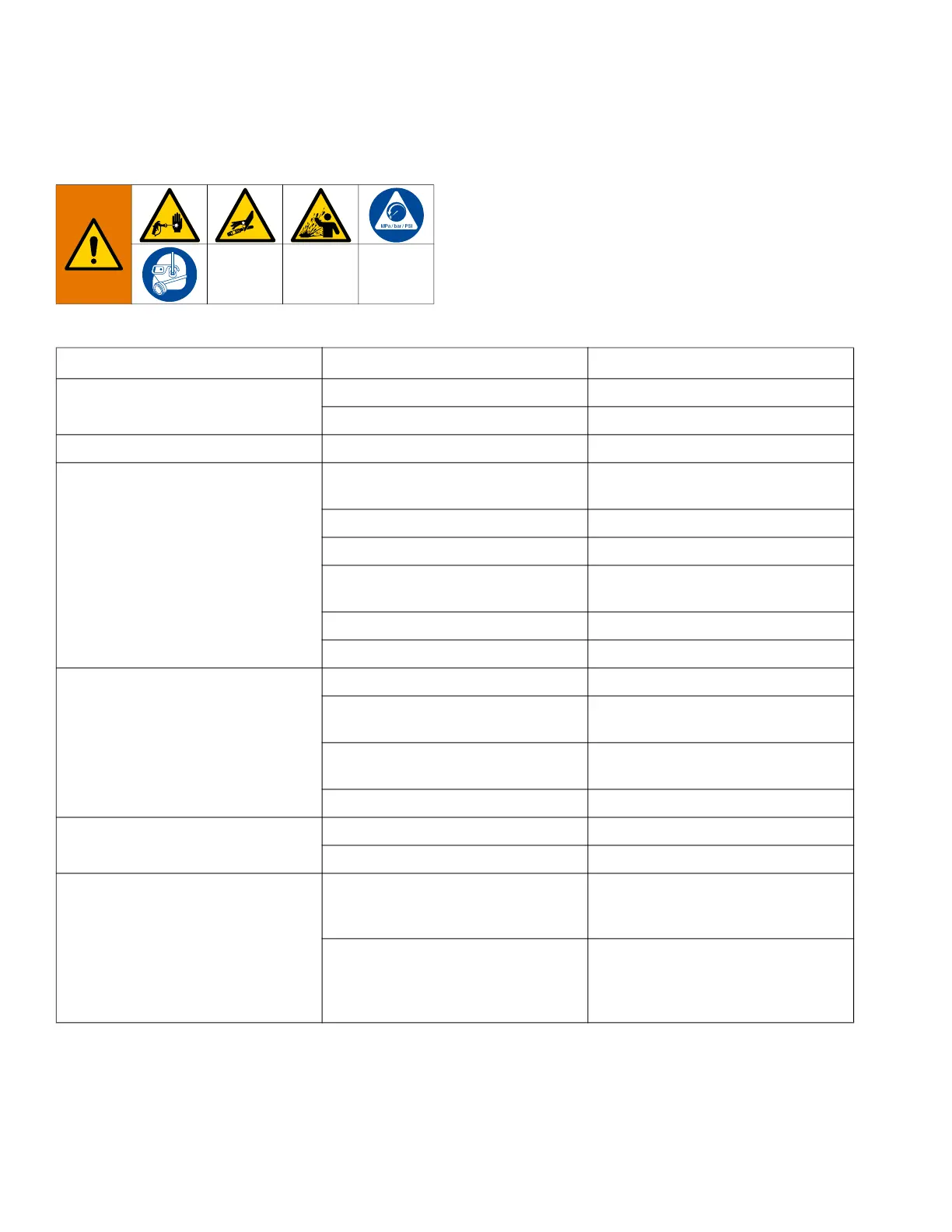

NOTE: check all possible solutions in the chart below

before you disassemble the regulator.

Problem Cause Solution

No pressure regulation Damaged diaphragm Replace diaphragm.

Leaking or dirty seat Replace cartridge, or clean seat.

No fluid flow Damaged valve actuation Replace valve actuator.

Pressure creeps above setting Metal chip or contamination

between ball and seat

Replace cartridge, or clean seat

area.

Damaged diaphragm Replace diaphragm.

Damaged o-ring or improper seal Replace the o-ring under the seat.

Damaged or clogged air regulator or

line (air-operated regulator only)

Clear obstruction in line. Service

regulator if necessary.

Leaking or dirty seat Replace cartridge, or clean seat.

Large change in inlet pressure Stabilize regulator inlet pressure.

Pressure drops below setting Empty/clogged supply line Fill/flush supply line.

Damaged or clogged air regulator or

line (air-operated regulator only)

Clear obstruction in line. Service

regula- tor if necessary.

Using valve beyond its rated flow

capacity

Install valve for each spray gun or

dispensing valve.

Large change in inlet pressure Stabilize regulator inlet pressure.

Fluid leaks from spring housing Loose fluid housing Tighten the four cap screws.

Damaged diaphragm Replace diaphragm.

Chatter Excessive pressure differential

between pump and gun

Reduce pump pressure to not more

than 2000 psi (14 MPa, 138 bar)

greater than required gun pressure.

Excessive flow rate Reduce fluid flow through regulator.

Connect only one spray gun or

dispensing valve to each fluid

regulator

Loading...

Loading...