Installation

308647T 9

The installations shown in FIG. 1 are only a guide for

selecting and installing a circulating or direct system;

they are not actual system designs. Contact your

Graco distributor for assistance in designing a system

to suit your needs.

NOTE: Before you install the regulator, thoroughly flush

the system to remove metal chips and other

contaminants. A fluid filter (D) of 60-mesh or finer

should always be installed upstream of the regulator.

Connections

Install the fluid regulator (G) in the spray gun fluid

supply line (F), as shown in the typical installation

drawings on this page. Connect only one spray gun or

dispensing valve to each fluid regulator.

Apply pipe sealant to the male pipe threads, and

connect the fluid supply line (F) to the fluid regulator’s

3/8 npt(f) inlet. Connect the line from the gun (J) to the

fluid regulator’s 3/8 npt(f) outlet. Install the gauge or

plug into the 1/4 npt(f) gauge port.

Make sure the direction of fluid flow agrees with the IN

and OUT markings on the regulatory body.

Flush the System

The regulator was tested in lightweight oil. Flush the

entire system with a solvent compatible with the fluid

being dispensed. Then test the system.

Mounting Bracket

A Mounting Bracket is available for mounting the

regulator. Order Part 222515 for the bracket and

mounting hardware.

Grounding

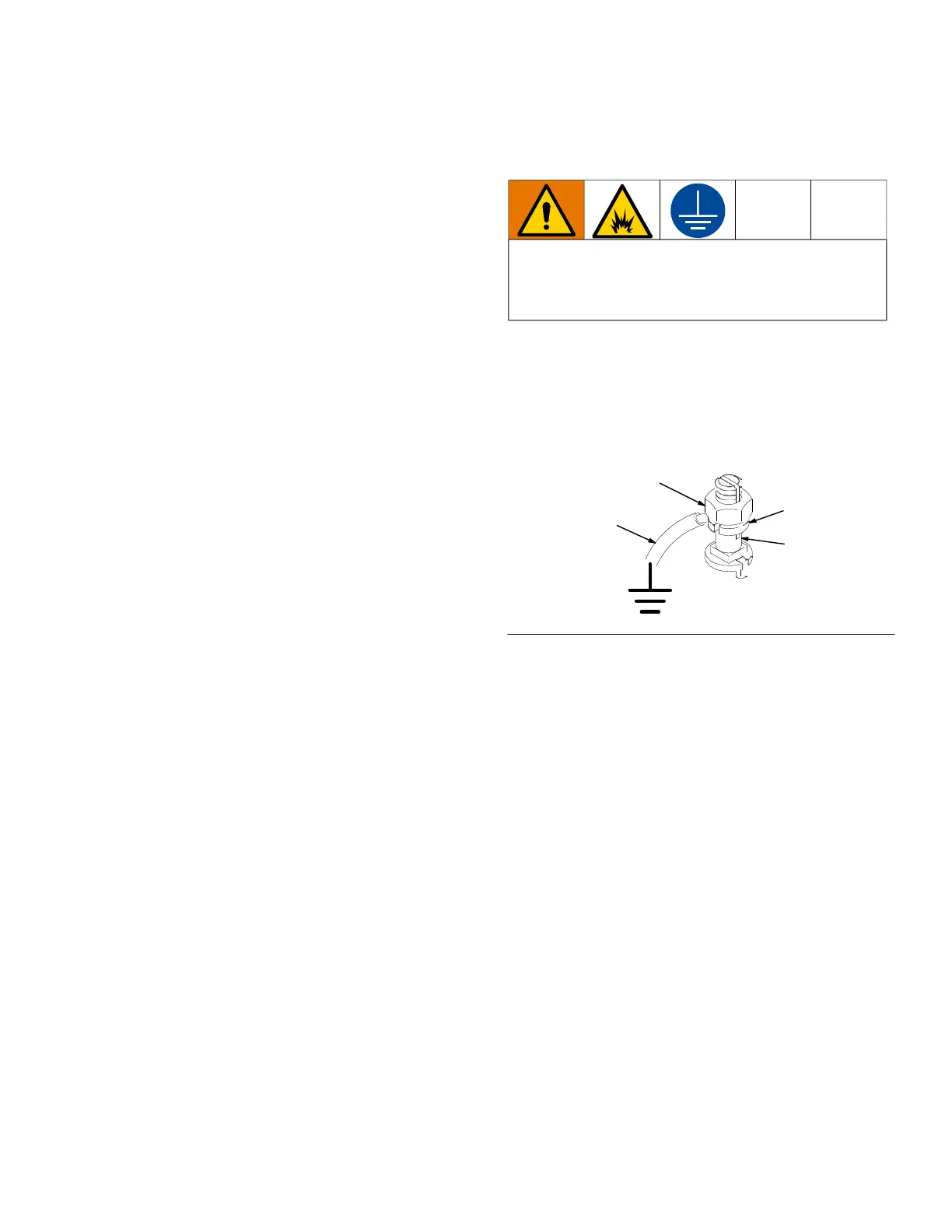

Pump: use a ground wire and clamp. Loosen the

grounding lug locknut (W) and washer (X). Insert one

end of a 1.5 mm2 (12 ga) minimum ground wire (Y) into

the slot in lug (Z) and tighten the locknut securely.

Connect the other end of the wire to a true earth

ground. Order Part 237569 Ground Wire and Clamp.

Air and fluid hoses: use only electrically conductive

hoses.

Heaters: if used, see the heater instruction manual.

Air compressor: follow manufacturer’s

recommendations.

Spray gun: ground through connection to a properly

grounded fluid hose and pump.

Fluid supply container: follow your local codes and

regulations.

Object being sprayed: follow your local codes and

regulations.

Solvent pails used when flushing: follow your local

codes and regulations. Use only conductive metal pails,

placed on a grounded surface. Do not place the pail on

a nonconductive surface, such as paper or cardboard,

which interrupts grounding continuity.

To maintain grounding continuity when flushing or

relieving pressure: hold metal part of the spray gun

firmly to the side of a grounded metal pail, then trigger

the gun.

The equipment must be grounded to reduce the risk

of static sparking. Static sparking can cause fumes

to ignite or explode. Grounding provides an escape

wire for the electric current.

FIG. 2

W

Y

X

Z

0864

Loading...

Loading...