psi

bar

MPa

17309674

Pressure Control Repair

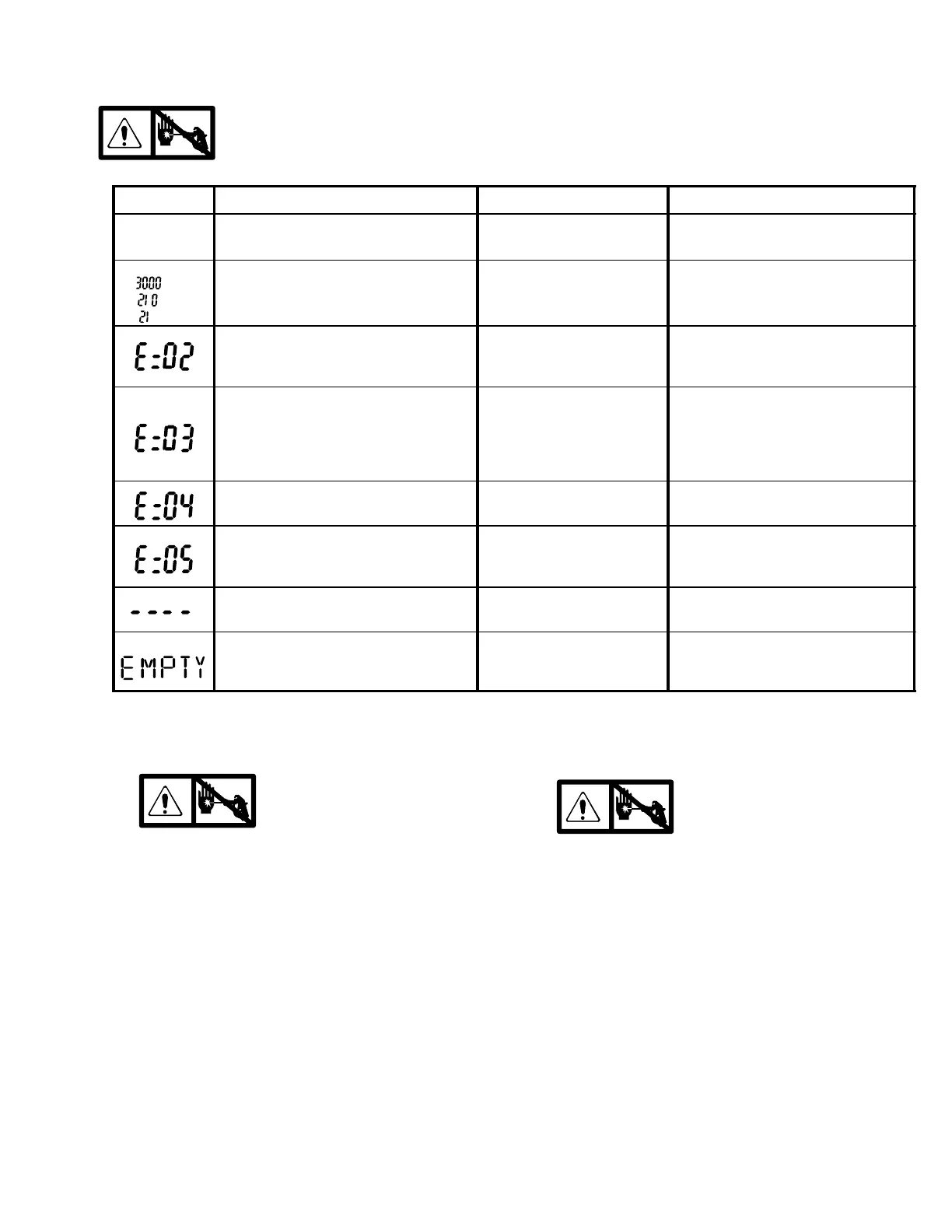

Digital Display Messages

No display does not mean that sprayer is not pressurized. Relieve pressure before repair; page 4.

DISPLAY

SPRAYER OPERATION

INDICATION ACTION

No Display

Sprayer stops. Power is not ap-

plied. Sprayer may be pressurized.

Loss of power Check power source. Relieve pres-

sure before repair or disassembly.

Sprayer is pressurized. Power is

applied. (Pressure varies with tip

size and pressure control setting.)

Normal operation Spray

Sprayer may continue to run. Power

is applied.

Pressure greater than 4500

psi (310 bar, 31 MPa) or

pressure transducer faulty

Replace pressure control board or

pressure transducer.

Sprayer stops. Power is applied.

Pressure transducer faulty,

bad connection or broken

wire.

Check transducer connection.

Open drain valve. Substitute new

transducer for transducer in spray-

er. If sprayer runs, replace trans-

ducer.

Sprayer stops. Power is applied.

Line voltage too high Check for voltage supply problem

Sprayer does not start or stops.

Power is applied.

Motor fault Check for locked rotor, shorted wir-

ing or disconnected motor. Repair

or replace failed parts.

Power is applied.

Pressure less than

200 psi (14 bar, 1.4 MPa)

Increase pressure if desired. Drain

valve may be open.

Sprayer stops. Power is applied.

Empty paint pail. Loss of

pressure.

Refill paint pail. Check for leaks or

clogged pump inlet. Repeat Start-

up procedure.

Pressure Control Transducer

Removal

Refer to Fig. 10 or 11 depending on sprayer voltage.

1.

Relieve pressure; page 4.

2. Remove four screws (12) and cover (50).

3. Disconnect lead (E) from motor control

board (49).

4. Remove two screws (47) and filter housing (15).

5. Thread transducer lead plastic connector down

through transducer grommet (20).

6. Remove pressure control transducer (38) and

packing o-ring (3) from filter housing.

Installation

1. Install packing o-ring (3) and pressure control

transducer (38) in filter housing (15). Torque to

30–35 ft-lb.

2. Thread transducer lead plastic connector up

through transducer grommet (20).

3. Install filter housing (15) with two screws (47).

4. Connect lead (E) to motor control board (49).

5. Install cover (50) with four screws (12).

Pressure Adjust Potentiometer

Removal

Refer to Fig. 10 or 11 depending on sprayer voltage.

1.

Relieve pressure; page 4.

2. Remove four screws (12) and cover (50).

3. Disconnect all leads from motor control board (49).

4. Remove six screws (6) and board (49)

5. Remove potentiometer knob (11), nut (37a) and

pressure adjust potentiometer (37).

Installation

1. Install pressure adjust potentiometer (37), nut

(37a) and potentiometer knob (11).

a. Turn potentiometer fully clockwise.

b. Install knob at full clockwise position.

2. Install board (49) with six screws (6).

3. Connect all leads to motor control board (49). See

Fig. 10 for 100, 120 Vac and Fig. 11 for 110, 240

Vac.

4. Install cover (50) with four screws (12).

Loading...

Loading...