PINION,

CLUTCH,

CLAMP,

FIELD

&

ENGINE

Disassembling these parts can start from the pinion hous-

'

If

startlng

ffom

the

clutch,

see page 34.

ing or from the clutch,

if

no pinion sewice is needed.

If

sfarflng

from

the

plnlon

houslng,

first follow Steps 1

to

6

of

DRIVE HOUSING,

on page 31, and then continue

with the procedure below.

PINION HOUSING

Removing the Pinion Housing

WARNING

Toreducethe riskof serious bodily injury, alwaysfol-

low the

Pressure Relief Procedure Warning

on

page 24 before repairing

the

sprayer.

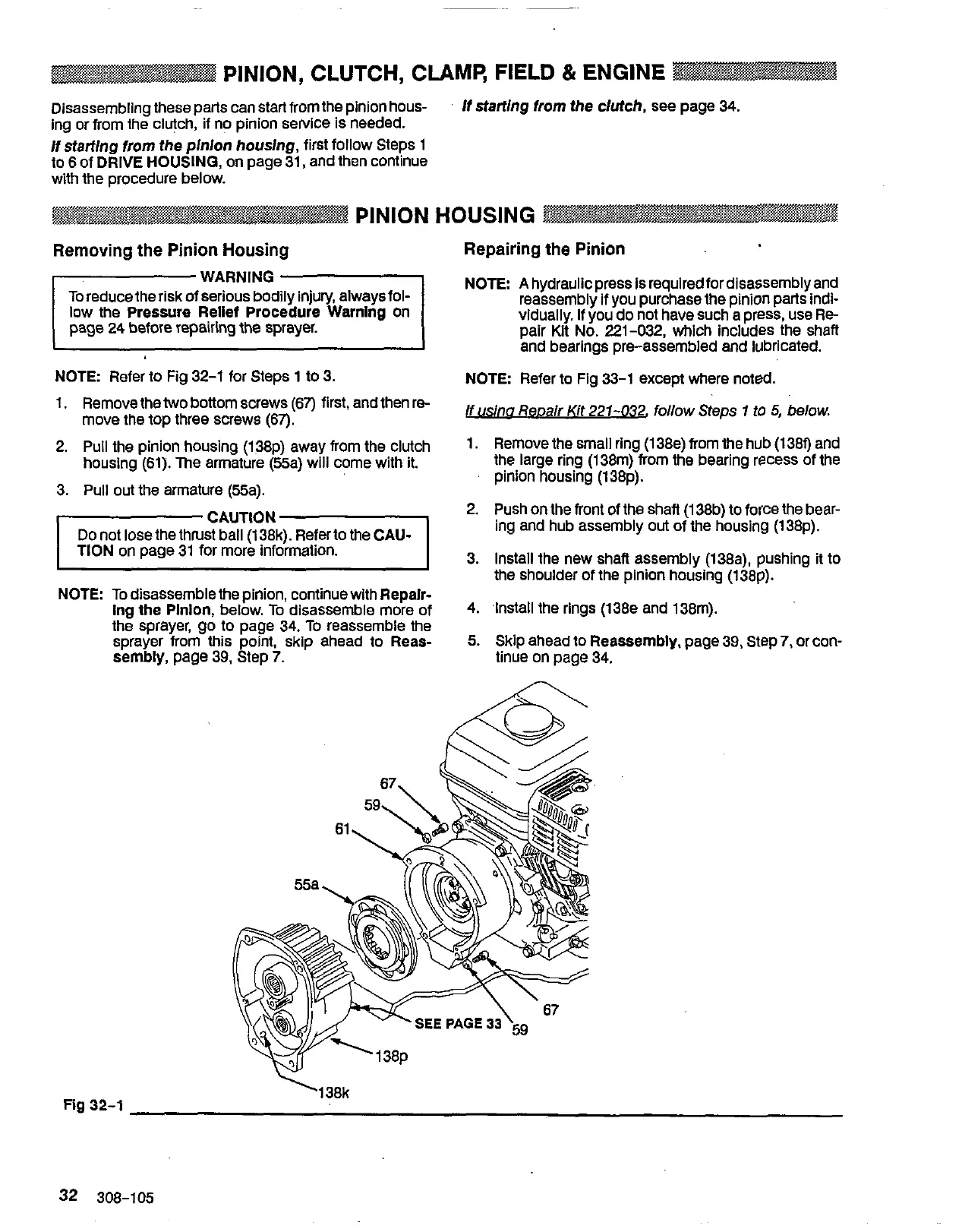

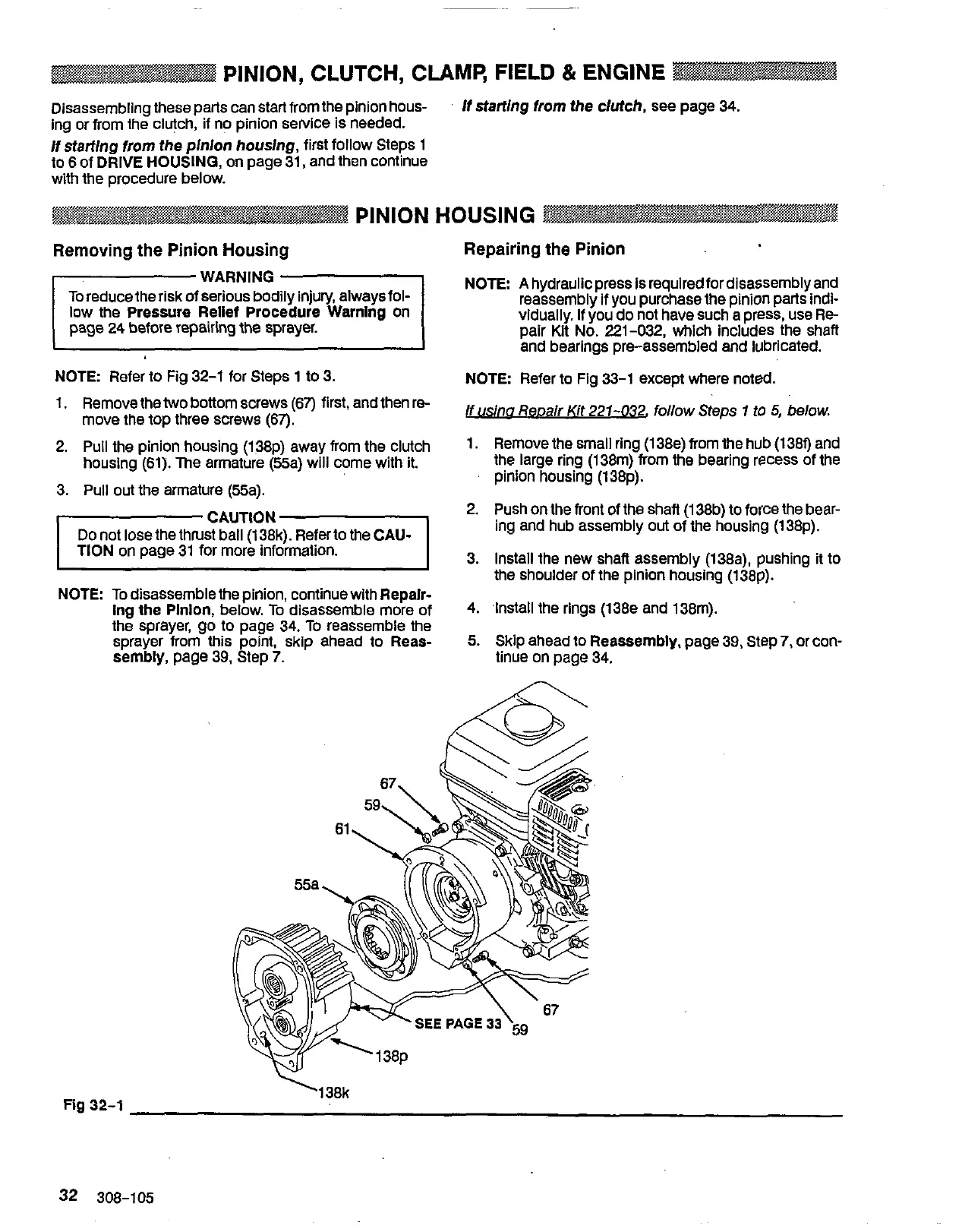

NOTE:

Refer to Fig 32-1 for Steps

1

to

3.

1.

Removethetwo bottom screws

(67)

first, andthen

re-

2. Pull the pinion housing (138p) away from the clutch

3. Pull

out

the armature (55a).

move the top three screws

(67).

housing (61).

me

armature (Sa) will come with it.

Do

not losethe thrust ball (138k). Referto the

CAU-

TlON

on page 31 for more information.

CAUTION

NOTE

To disassemble the pinion, continue with

Repalr-

ing the Plnlon,

below. To disassemble more of

the sprayer, go to page 34.

To

reassemble the

sprayer from this point, skip ahead to

Reas-

sembly,

page 39, Step

7.

Repairing the Pinion

NOTE

A

hydraulic press

isrequiredfordisassemblyand

vidually. If you do not have such a press, use

Re

reassembly If you purchase the pinion parts indi-

pair Kit

No.

221-032, which includes the shaft

and bearings pre-assembled and lubricated.

NOTE

Refer

to

Fig 33-1 except where noted.

If

usina

ReDair

Kit

221-032,

follow

Sreps

7

to

5,

below.

1.

2.

3.

4.

5.

Remove the small ring (138e) from

the

hub (1389 and

the large ring (138m) from the bearing recess

of

the

pinion housing (138p).

Push on the front of the shafl(l38b)

lo

force the bear-

ing

and hub assembly out of the housing (138~).

the shoulder

of

the pinion housing (138p).

Install the new shafl assembly (138a), pushing

it

to

,Install the rings (138e and 138m).

Skip ahead

to

Reassembly,

page 39, Step

7,

or con-

tinue on page 34.

Fig

32-1

32

308-105

Loading...

Loading...