-

PRESSURE

CONTROL CALIBRATION

(See

Fig

25)

an injection injury or other serious bodily injury which can result from component rupture, electric shock, fire, ex.

USE EXTREME CAUTION WHEN PERFORMING THIS CALIBRATION PROCEDURE to reduce the risk

oi

plosion, or moving parts.

This procedure

sets

the sprayer to

2500

psi

1172

bar)

MAXIMUM WORKING PRESSURE. by performing these calibrations in any

other way.

NEVER attempt to increase the fluid outlet pressure

This procedure must be performed whenever

a

NEVER EXCEED

2500

psi

(172

bar) MAXIMUM

microswitch or pressure control assembly is removed sprayer

at

higher pressures could result in compo-

WORKING PRESSURE, Normal operation of the

and reinstalled or replaced to be sure

the sprayer is

properly calibrated.

nant rupture, fire or explosion.

Improper calibration can cause the sprayer to over-

ALWAYS

use

a

new

50

foot

(15.2

m) spray hose

pressurize and result in component rupture, fire or

rated for

3OOO

psi

1210

bar) MAXIMUM WORKING

explosion.

It

may

also

prevent the sprayer from ob-

PRESSURE when performing this procedure. A

taining the maximum working pressure which would

used,

underrated hose could develop

a

high pressure

leak or rupture.

result in poor sprayer performance.

AVOID touching the wire in the pressure control

reduce the risk of electric shock,

-.

assembly when the control box cover is removed to

Tools

Needed:

NEW

50

ft

(15.2

m)

3ooo

psi

(210

bar) airless spray

Needle Valve. Part No.

102

-

715

or

103-067

hose, Part No.

210

-

541

3/8"

open eid wrench

Fluid

-

Filled Pressure

Gauae.

Part No.

102-814

~~~ ~ ~ ~ ~~~~

".

5~gallon pail and water

Mineral Spirits (for flushing after test)

1.

Follow the Pressure Relief Procedure Warning

on page

14.

Install the new

50

ft

(15.2

m) spray

hose to the sprayer outlet. On the other end of

the

hose install the needle valve. Install the fluid

-

filled

pressure gauge in the top port of the fluid filter.

2.

Open the needle valve

slightly.

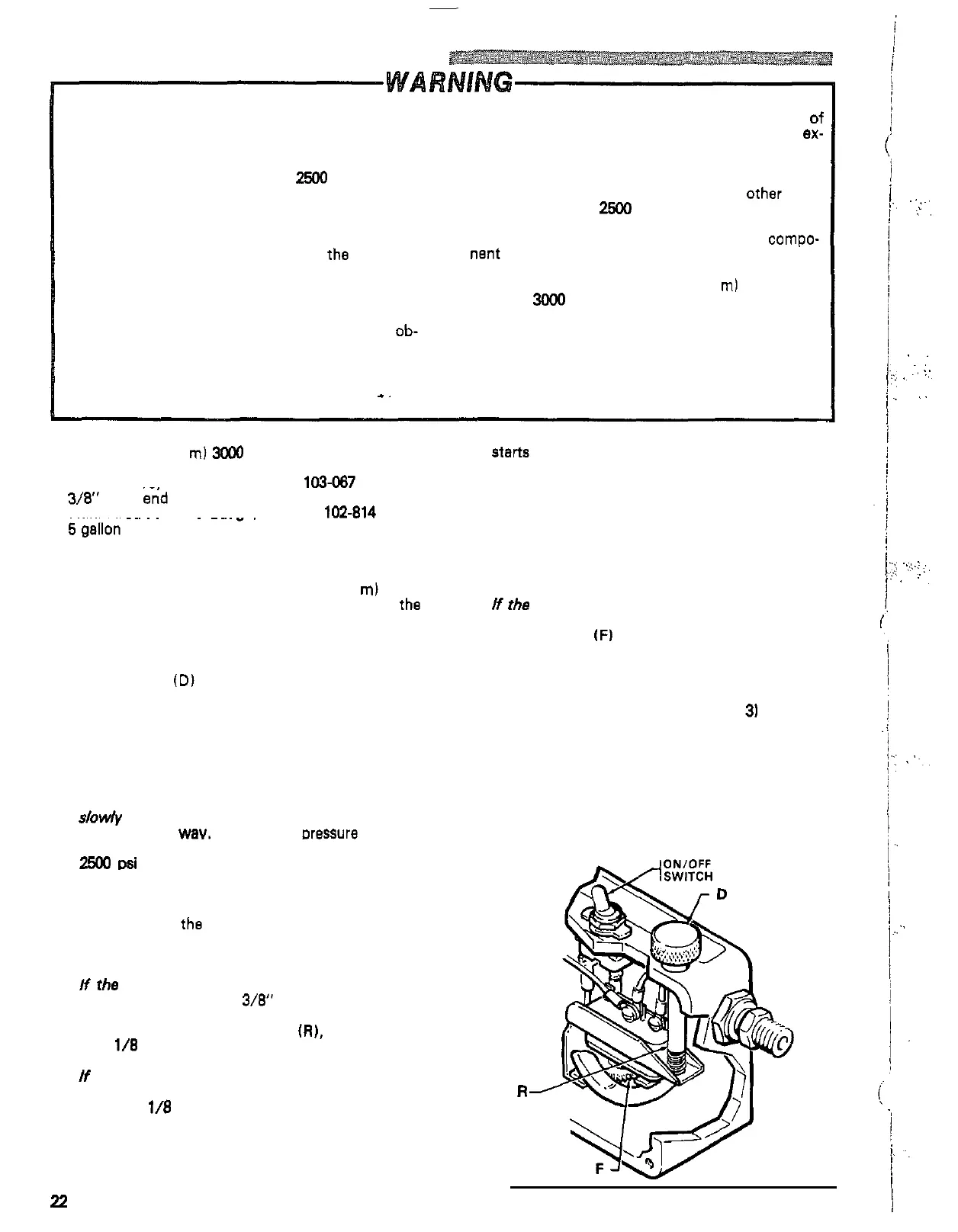

Turn the pressure

control knob

(D) to the minimum setting. Plug in

the sprayer and turn the switch ON. Increase the

pressure setting just enough to start the sprayer.

Prime the hose, being sure to eliminate

all

air from

the system.,

3.

Open the needle valve

a

little more

-

enough to.

allow the pump to run continuously

-

and turn the

slowly

start

to close the needle valve, but don't

pressure control knob to maximum. Now,

very

close

it

all

the way. Observe the Dressure

at

which

4.

Now check to

see

at

whet pressure the sprayer

starts to run again after stalling. Plug in the sprayer,

turn

it

on, close the needle valve, and set the

pressure

at

maximum. Allow the sprayer to run until

it

stalls.

5.

Now open the needle valve very slowly while ob-

serving the pressure gauge. Check to

see

if the

pressure drops to approximately

2100

psi

(147

bar)

before starting again.

N

the pressure

is

lower:

shut

off

and unplug the

sprayer, but do not relieve pressure. Turn the dif-

ferential wheel

(F)

counterclockwise

just one notch

end repeat Steps

4

and

5.

Check the pressure drop

again, and repeat if necessary.

NOTE:

If

you adjust the differential wheel, recheck

the stall pressure (steps

2

and

3)

to be sure

the

stall

pressure has not changed.

6.

Follow the Pressure Relief Procedure Wernlng

on page

14,

flush the water out with mineral spirits,

relieve pressure again, then remove the test hose,

needle valve and pressure gauge.

f

the pump stalls, 'which should

be

approximately

2500

psi

(172

bar).

NOTE:

The slower the pressure

is

brought up, the

easier

it

is

to note the exact

stall

pressure.

pressure to rise too

fast

which gives

a

false

Closing

the needle valve quickly causes the

reading.

N

the pressure

is

lower:

unplug the sprayer and

turn the pressure adjustment nut,

at

the bottom of

relieve pressure. Use

a

3/8"

open end wrench to

the pressure control knob shaft

IR),

counterclock

-

wise

1/8

turn or

less,

then repeat steps

2

and

3.

If the pressure

is

higher:

unplug the sprayer and

relieve pressure. Turn the pressure adjustment nut

clockwise

1/8

turn or

less

and repeat steps

2

and

3.

Repeat until the proper stall pressure is obtained.

22

307

-

724

R

Fig

25

yfl

..

..

,

...

,.

..

.

..

..

..

..

..

~.

....

..

.

..

..

,

.

.,.

'..

..

,.

.

.,,

~

.'

:

.

:.

..

:

...

..

..

..

.

..

,.

..

.

,

..

Loading...

Loading...