Component Identification

8 333182A

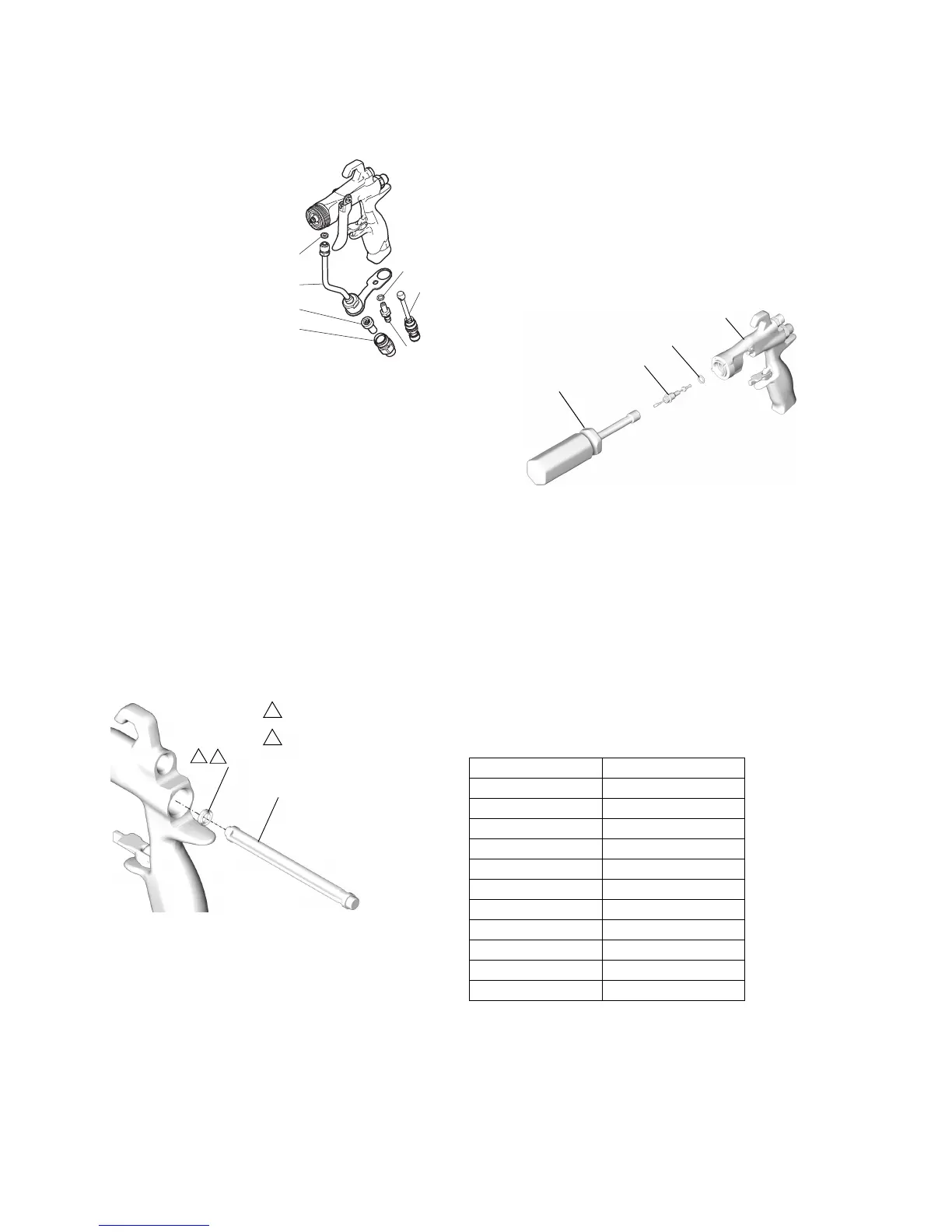

Fluid Tube Replacement (16)

1. Remove the air inlet fitting

(17) using the gun tool (30)

and remove the screw (20).

2. Unscrew the fluid inlet fitting

(25). Remove and clean or

replace the inline fluid filter

(24).

3. Unscrew fluid tube connector

(16a) from fluid inlet. Carefully

remove gasket (22).

Flat Tip Conversion Kit (Optional)

The Flat Tip Conversion Kit allows AAM Flat Tips to be used

with this gun. Order part number 288514.

Reassembly

1. Install the tube gasket (22) in the gun. Hand tighten the

fluid tube connector (16a) into the gun’s fluid inlet. Anti-

gens the air inlet fitting (17) and screw (20). Torque the

fluid tube connector to 150-160 in-lb (17-18 N•m). Torque

the air inlet fitting to 175-185 in-lb (20-21 N•m). Torque

the fluid tube bracket screw to 50-60 in-lb (6-7 N•m).

2. Install the inline fluid filter (24) into the base of the fluid

tube (16). Screw the fluid inlet fitting (25) into the base of

the tube. Torque to 175-185 in-lb (20-21 N•m).

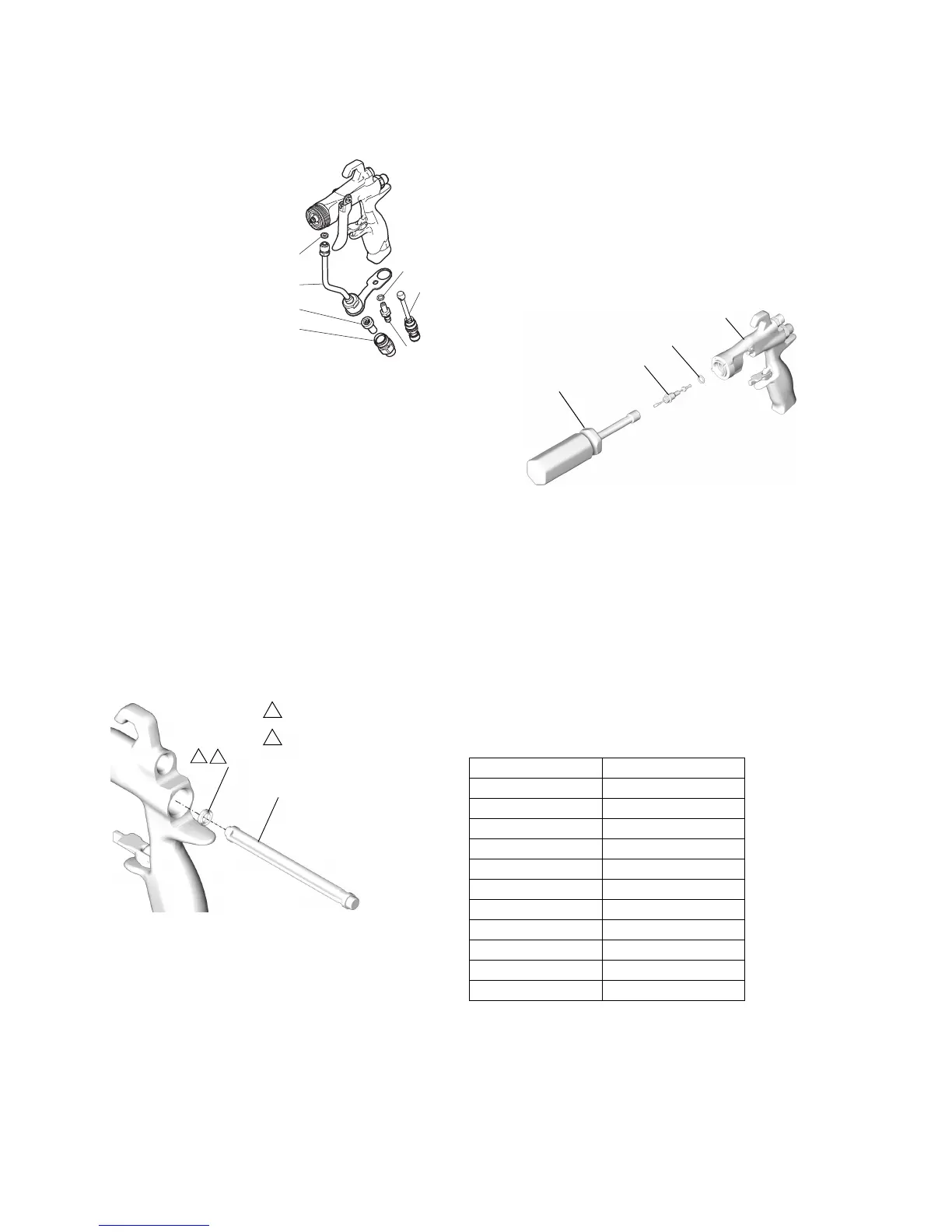

3. Place the new u-cup (7) on the seal installation tool (28),

with the u-cup lips facing the tool. Push the u-cup into the

back of the gun until you feel a definite snap.

4. Lubricate the front end of the air valve assembly (8).

Gently slide the air valve assembly into the back of the

gun, passing through the u-cup (7), as far as it will go. Be

careful not to damage the u-cup.

5. Slide the seat (10) onto the shaft (9). Be sure that the

tapered end of the seat is toward the thicker end of the

shaft. Carefully insert the shaft (9) and seat (10) in the air

valve (8).

6. Install the two springs (15 and 19). Screw the spring cap

(11) into the back of the gun body. Torque to 175-185

in-lb (20-21 N•m).

7. Lightly lubricate the needle assembly o-rings and shaft

where the packing slides. Be sure that the o-ring (2a) is in

place in the gun body (1).

8. Insert the fluid needle assembly (2) into the front of the

gun. Use the nut driver (29) to screw the fluid needle

assembly into the gun body (1) and torque to 50-60 in-lb

(6-7 N•m).

9. Install the trigger (3), pivot pin (13), and nut (14). Use low

strength thread locker and be sure that the brass piece of

the fluid needle assembly (2) is behind the trigger.

Lubricate both sides of the pivot pin where the trigger

contacts the pin and lubricate the boss on both sides of

the gun where the trigger contacts the gun body. Torque

the nut to 20-30 in-lb (2-3 N•m).

10. Trigger the gun to pull the needle back while you screw

the diffuser assembly (5) into the gun body (1) using the

gun tool (30). Torque to 155-165 in-lb (18-19 N•m). When

properly tightened, the flange will bottom out on the gun.

11. Attach the guard (6) and spray tip (33), page 5.

Translated Manuals

Translated manuals can be obtained from a distributor

or by visiting www.graco.com.

18

16

37

38

75

20

17

ti22690a

ti6578a

7

28

Lubricate lightly.

Lips face out of gun body.

3

8

3

8

Spanish - 333183 Estonian - 333195

French - 333184 Latvian - 333196

Dutch - 333185 Lithuanian - 333197

German - 333186 Polish - 333198

Italian - 333187 Hungarian - 333199

Turkish - 333188 Czech - 333200

Greek - 333189 Slovakian - 333201

Croatian - 333190 Portuguese - 333202

Danish - 333191 Finnish - 333203

Chinese - 333192 Swedish - 333204

Japanese - 333193 Norwegian - 333206

Korean - 333194 Russian - 333207

29

2

2a

1

ti6575a

Loading...

Loading...