3A3212C

EN

Operation, Parts

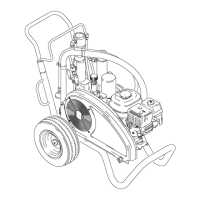

GX Electric Airless

Sprayers

For professional use only.

Not approved for use in explosive atmospheres or hazardous locations.

For portable airless spraying of architectural paints and coatings.

Models: GX

3000 psi (207 bar, 20.7 MPa) Maximum Working Pressure

See page 4 for additional model information.

Important Safety Instructions

Read all warnings and instructions in this manual, related manuals, and on the unit

including the power cord. Be familiar with the controls and the proper usage of the

equipment. Save these instructions.

Related Manuals

Gun – 311861 (FTX) 312830 (SG3) Pump – 3A3172

ti272

Use only genuine Graco replacement parts.

The use of non-Graco replacement parts may void warranty.