INSTRUCTIONS–P

ARTS LIST

307–847

Rev. L

Supersedes K

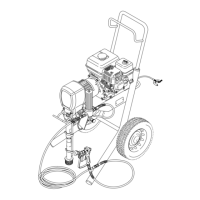

5 HORSEPOWER, GASOLINE–POWERED

GM

5000

Airless

Paint Sprayer

3000 psi (210 bar) Maximum Working Pressure

Sprayers with Upright Carts

Model 220–886, Series C

Basic

sprayer

, without hose or gun

Model 231–052

Complete

sprayer

, with hose and Contractor gun,

RAC IV

DripLess

T

ip Guard,

and 517 size SwitchT

ip

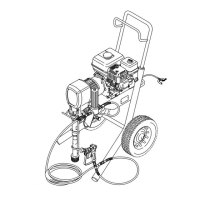

Sprayers with Lo–Boy Carts

Model 222–488, Series A

Basic

sprayer

, without hose or gun

Model 231–085

Complete

sprayer

, with hose and Contractor gun,

RAC IV

DripLess

T

ip Guard,

and 517 size SwitchT

ip

GRACO INC. P.O. BOX 1441

MINNEAPOLIS, MN

55440–1441

COPYRIGHT

1987, GRACO INC.

This manual contains important

warnings and information.

READ AND RETAIN FOR REFERENCE

0136

Liquids can be injected into the body by high pressure airless

spray

or leaks – especially hose leaks.

Keep

body clear of the nozzle. Never stop leaks with any part of the

body.

Drain

all pressure before removing parts. A

void accidental

triggering

of gun by always setting safety latch

when not spraying.

Never

spray without a tip guard.

In case of accidental skin injection, seek immediate “Surgical

Treatment”.

Failure

to follow this warning can result in amputation or serious

injury.

FIRE

AND

EXPLOSION HAZARD

SKIN INJECTION

HAZARD

READ AND UNDERSTAND ALL LABELS AND INSTRUCTION MANUALS BEFORE USE

Spray

painting, flushing or cleaning equipment with flammable liq

-

uids

in confined areas can result in fire or explosion.

Use

outdoors or

in extremely well ventilated areas. Ground equip

-

ment,

hoses, containers and objects being sprayed.

Avoid all ignition sources such as static electricity from plastic

drop

cloths, open flames such as pilot lights, hot objects such as

cigarettes,

arcs from connecting or disconnecting

power cords or

turning

light switches on and off.

Failure

to follow this warning can result in death or serious injury

.

NOTE: This

is an example of the DANGER label on your sprayer

.

This label is available in other languages, free of charge. See page 42 to order

.